Method for preparing bismuth vanadate/bismuth ferrite heterojunction film solar cells

A solar cell and heterojunction technology, which is applied in the manufacture of circuits, electrical components, and final products, to achieve superior photovoltaic performance, simple preparation methods, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

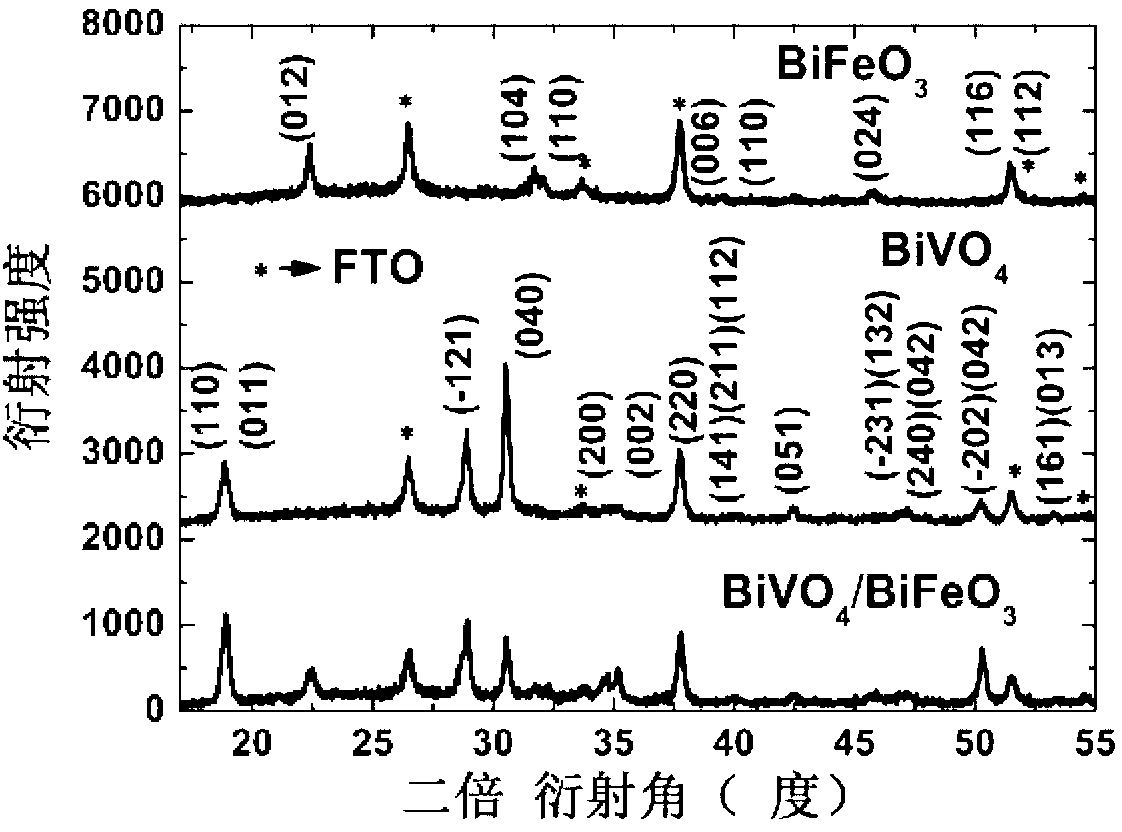

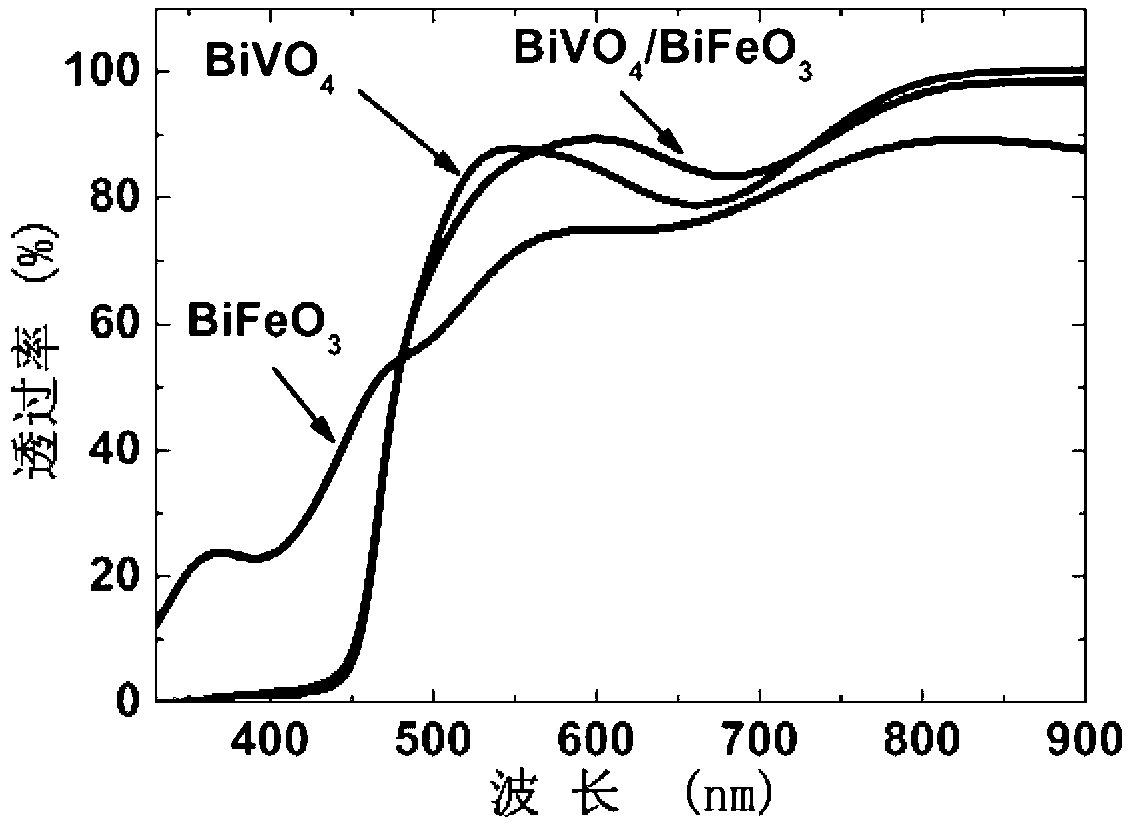

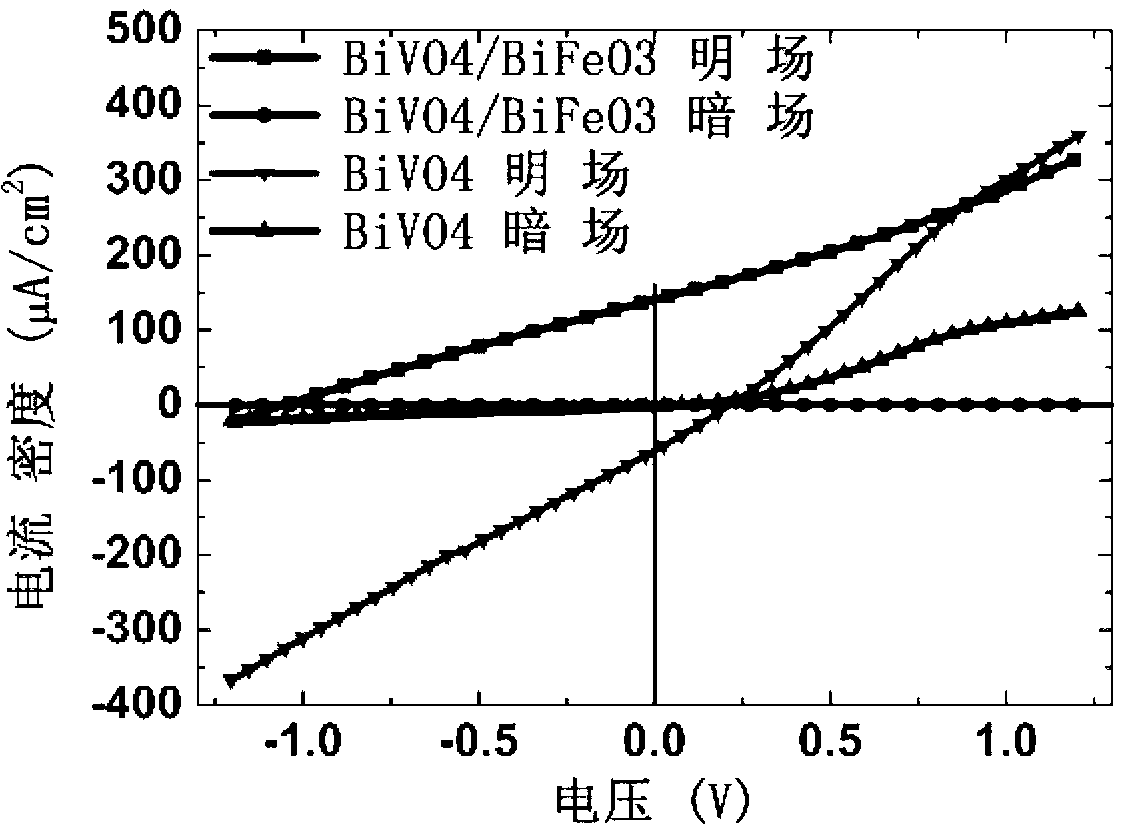

[0029] First Bi(NO 3 ) 3 ·5H 2 O and Fe(NO 3 ) 3 9H 2 O (molar ratio according to Bi:Fe=1:1) configure BiFeO with DMF as solvent 3 Precursor solution, the concentration of the precursor solution is 0.2mL / cm 2 . Secondly, Bi(NO 3 ) 3 ·5H 2 O and NH 3 VO 3 (Molar ratio according to Bi:V=1:1) proportionally and dissolved in DMF with the assistance of citric acid, acetic acid and ethanolamine, BiVO 4 precursor solution. BiVO was then prepared by the gel-spinning method 4 / BiFeO 3 heterojunction films. The conditions for throwing glue are: 1) Ultra-thin BiFeO 3 Layer preparation: Spin the glue at 500 rpm for 10 seconds and then at 3000 rpm for 30 seconds. After spinning the glue, dry the substrate with the precursor wet film on a hot plate at 350°C for 1 to 3 minutes, and finally dry it in O 2 Ultrathin BiFeO was prepared by sintering at 550 °C for 5 minutes in a rapid annealing furnace under atmosphere 3 layer; 2) BiVO 4 Layer: Spin the glue at 500rpm for 10 se...

Embodiment 2

[0032] First Bi(NO 3 ) 3 ·5H 2 O and Fe(NO 3 ) 3 9H 2 O (molar ratio according to Bi:Fe=1:1) configure BiFeO with DMF as solvent 3 Precursor solution, the concentration of the precursor solution is 0.2mL / cm 2 . Bi(NO 3 ) 3 ·5H 2 O and NH 3 VO 3 (Molar ratio according to Bi:V=1:1) proportionally and completely dissolved in DMF with the assistance of citric acid, acetic acid and ethanolamine, BiVO 4 precursor solution. BiVO was then prepared by the gel-spinning method 4 / BiFeO 3 heterojunction films. The conditions for throwing glue are: 1) Ultra-thin BiFeO 3 Layer preparation: Spin the glue at 500 rpm for 10 seconds and then at 3000 rpm for 30 seconds. After spinning the glue, dry the substrate with the precursor wet film on a hot plate at 350°C for 1 to 3 minutes, and finally dry it in O 2 The ultra-thin BFO layer was prepared by sintering in a rapid annealing furnace at 600°C for 5 minutes under atmosphere; 2) BiVO 4 Layer: Spin the glue at 500rpm for 10 se...

Embodiment 3

[0035] First Bi(NO 3 ) 3 ·5H 2 O and Fe(NO 3 ) 3 9H 2 O (molar ratio according to Bi:Fe=1:1) configure BiFeO with DMF as solvent 3 Precursor solution, the concentration of the precursor solution is 0.2mL / cm 2 . Bi(NO 3 ) 3 ·5H 2 O and NH 3 VO 3 (Molar ratio according to Bi:V=1:1) proportionally and completely dissolved in DMF with the assistance of citric acid, acetic acid and ethanolamine, BiVO 4 precursor solution. BiVO was then prepared by the gel-spinning method 4 / BiFeO 3 heterojunction films. The conditions for throwing glue are: 1) Ultra-thin BiFeO 3 Layer preparation: Spin the glue at 500 rpm for 10 seconds and then at 3000 rpm for 30 seconds. After spinning the glue, dry the substrate with the precursor wet film on a hot plate at 350°C for 1 to 3 minutes, and finally dry it in O 2 The ultra-thin BFO layer was prepared by sintering in a rapid annealing furnace at 550°C for 5 minutes under atmosphere; 2) BiVO 4 Layer: Spin the glue at 500rpm for 10 se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com