Composite strand tapered anchoring steel strand finished product cable and manufacture method thereof

A steel strand and composite technology, applied in the field of cables, can solve the problems of steel wire corrosion, corrosion, high design and manufacturing costs, and achieve the effects of saving design costs, good anti-corrosion and sealing, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: A clip-type composite anchoring steel strand finished cable.

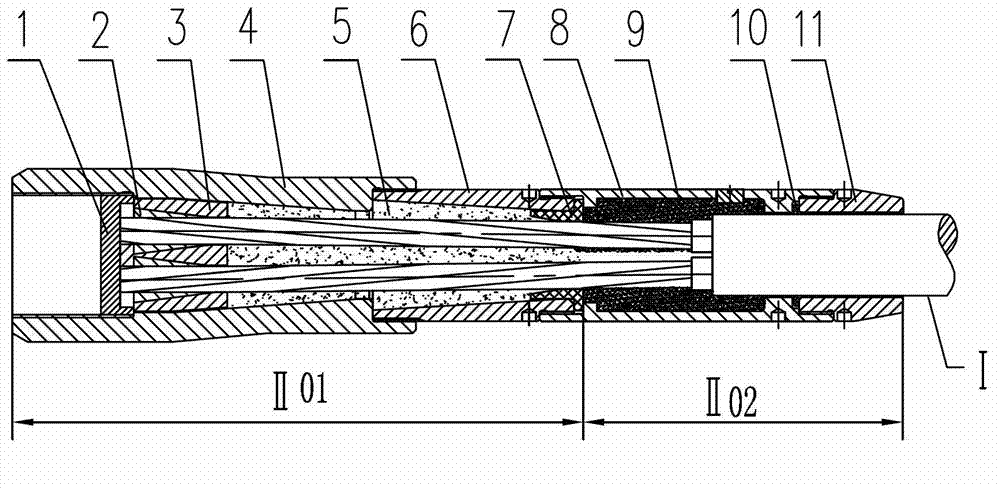

[0073] Such as figure 1 As shown, the clip-type composite anchoring steel strand finished cable includes a steel strand finished cable body I and two anchor ends located at both ends of the steel strand finished cable body I, and each anchor end includes an anchor clamping section II01 and Seal anti-corrosion section Ⅱ 02;

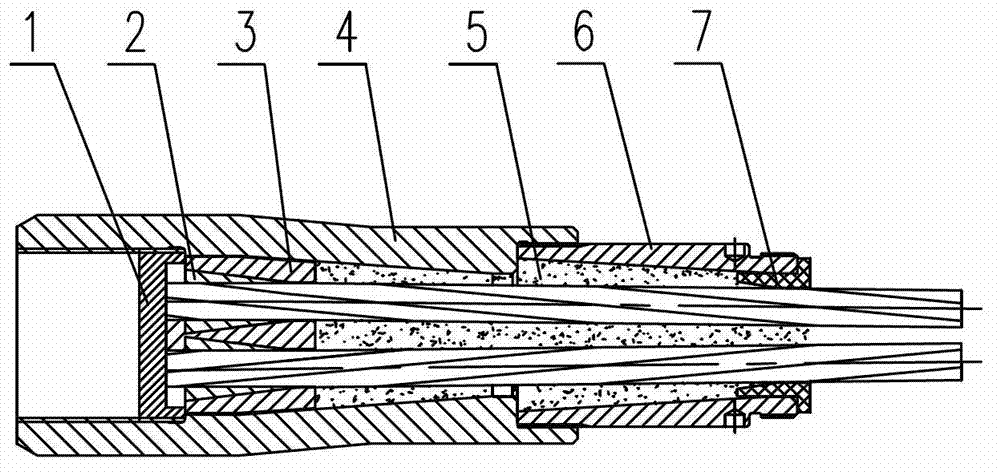

[0074] The anchor clamping section II01 includes an end cap 1, a clip 2, a split anchor plate 3, an anchor cup 4, an extension tube 6 and a restraint ring 7 (see figure 2 );

[0075] The split wire anchor plate 3 is a cone with an external taper, the inner cavity of the anchor cup 4 is an inner taper hole, and the inner hole of the extension tube 6 is also an inner taper hole;

[0076] Each single-strand steel strand of the finished steel strand cable body I is clamped on the sub-wire anchor plate 3 through the clip 2, and the sub-wire anchor plate 3 is located in the i...

Embodiment 2

[0084] Embodiment 2 A manufacturing method of a clip-type composite anchoring steel strand finished cable.

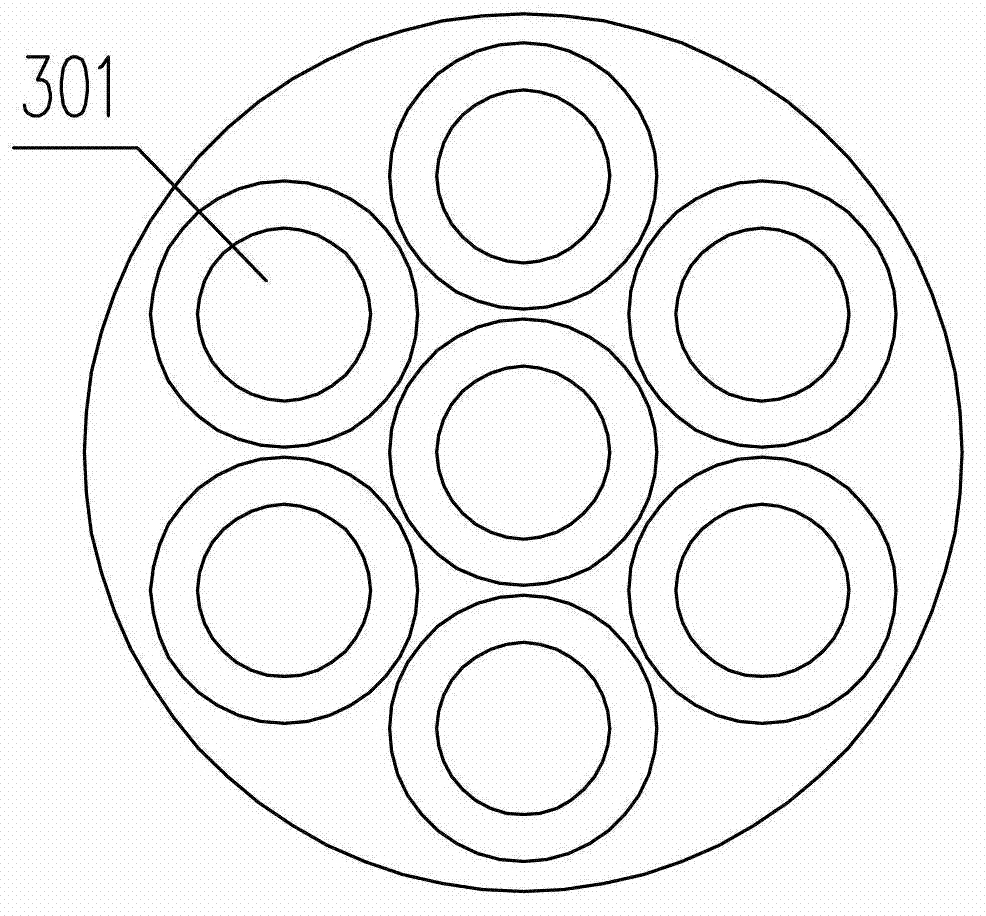

[0085] The cable body I of the clip-type composite anchoring steel strand finished cable is the finished steel strand cable body I1 composed of n single-strand steel strands (see Figure 6-1), and the steel strand finished cable body I1 is There is an inner PE sheath 102 outside each single-strand steel strand; the outer wrapping of n single-strand steel strands with the inner PE sheath is wrapped with a high-strength polyester tape 104, and the high-strength polyester tape 104 is extruded with Outer layer PE sheath 101, each single steel strand constituting the cable body I1 is galvanized, smooth or epoxy sprayed steel strand, n is 2, 3, 4, 5, ... 350 any number in

[0086] Its production process includes the following steps:

[0087] A. Remove a length of sheath from one end of the steel strand finished cable body I that constitutes the clip-type composite anchoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com