Bacillussp., microbial agent and applications of Bacillussp. and microbial agent

The technology of Bacillus cereus and microbial inoculum is applied in the application field of preparing ethanol, and can solve the problems of low cellulose degradation ability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Enrichment and isolation of cellulose-degrading strains

[0030] Take 10 g of sludge sample by aseptic operation, put it into a conical flask filled with 90 mL of sterile water and shake it for 30 min to make it fully mixed to form a 10-1 dilution. After clarification, take the supernatant and transfer it to the rich Collect culture medium; directly draw 10ml of the liquid sample to inoculate the enrichment medium, culture it at 30°C and 180 r. Continuous enrichment culture for 20 days.

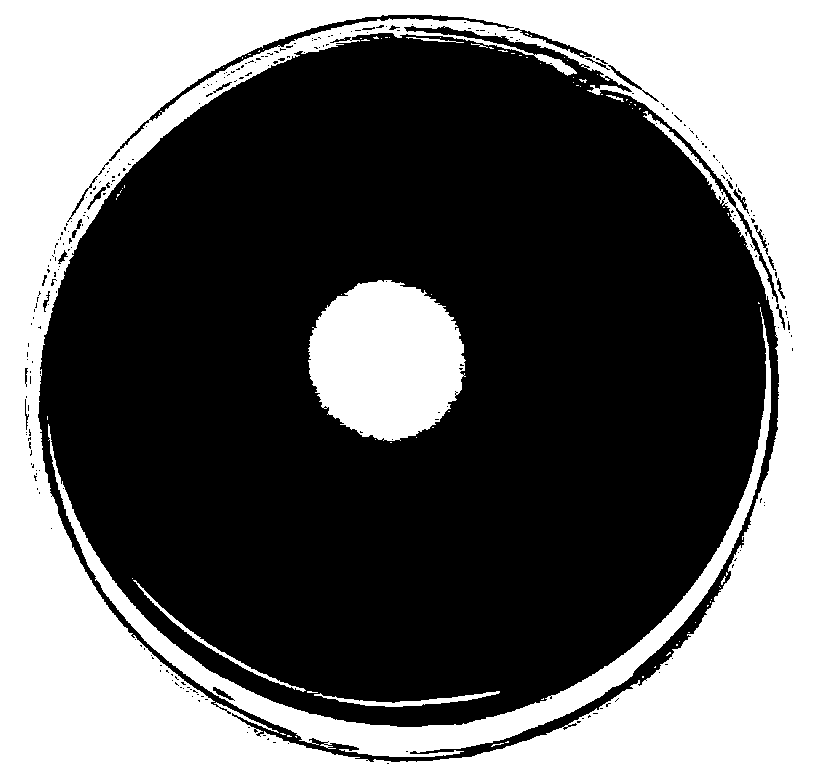

[0031] The enriched culture solution was made into 10-2, 10-3, 10-4 concentration dilution solution by gradient dilution method. Take 100 μL of 10-2, 10-3, and 10-4 dilutions and spread them on the primary screening medium plate. After culturing at 28°C for 1 to 2 days, duplicate the plate, and use Gram's iodine solution Submerge the parental plate for 3-5 minutes, the result is as follows figure 1 shown.

[0032] The strains with clear transparent circles around the colonies w...

Embodiment 2

[0037] According to the experimental content and experimental methods recorded in the "Common Bacteria System Identification Manual" [4] and "Actinomycete Systematic Principles, Methods and Practice" [5], the screened strains with the preservation number CGMCC No. 6895 were tested. Bacteria identification.

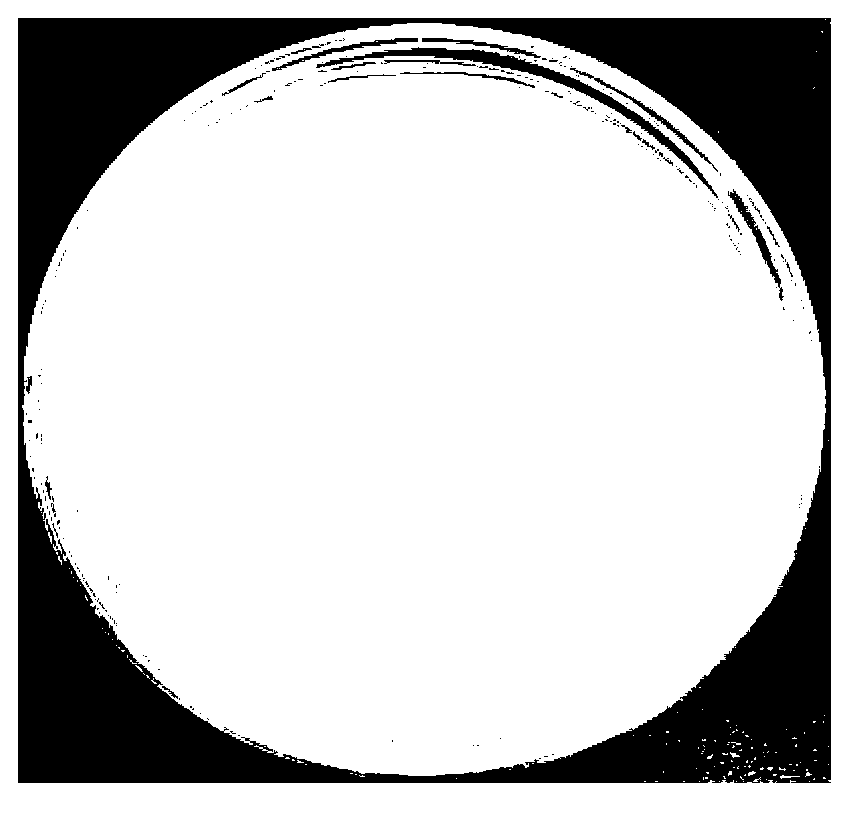

[0038] 1. Morphological analysis

[0039] The observation of the colony morphology of the strain with the preservation number CGMCC No. 6895 was carried out on a nutrient agar medium. After the strain was streaked and inoculated, it was incubated at a constant temperature of 28°C for 48 hours to observe the colony morphology. The colony of the strain with the preservation number CGMCC No. 6895 is white and slightly shiny, with a rough, flat, nearly round surface and irregular edges. The results are as follows: figure 2 shown.

[0040] 2. Identification of 16s rDNA

[0041] PCR amplification and sequencing of 16s rDNA: The total DNA of the strain with the preservation num...

Embodiment 3

[0050] (1) Inoculate 3 parts by weight of Bacillus sp. with the preservation number CGMCC No. 6895 in 100 parts by weight of nutrient broth medium (liquid), culture at 37°C, take samples during the culture process and pass Observation by direct counting method under microscope until the number of viable bacillus was 0.5×10 10 per gram of culture medium.

[0051] (2) Weigh 30g of bagasse (14.06g of cellulose) into a 500ml Erlenmeyer flask, then add the same amount of inorganic nutrient solution (MgSO 4 .7H 2 O 0.5g, KH 2 PO 4 1.0g, Na 2 PO 4 0.2g, MnSO 4 0.035g, CuSO 4 .5H 2 O 0.007g, FeSO 4 .7H 2 O 0.007g, distilled water 1000ml, sterilized).

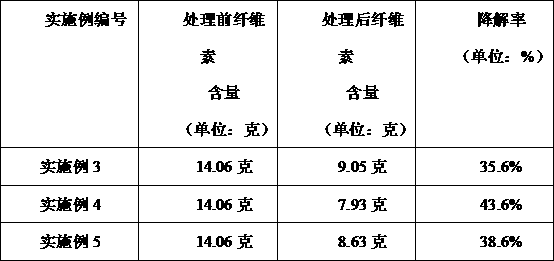

[0052] (3) The 0.5×10 obtained in step (1) 10 Each gram of culture medium (10 g) was added to the Erlenmeyer flask in step (2). The Erlenmeyer flask was placed in a biochemical incubator at 30°C for static culture for 30 days, and the water content was controlled at about 70%. The results of the cellulose content after 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com