Environmentally-friendly polyurethane composition for making carpet backing material, and its preparation method

A carpet backing and polyurethane technology, which is applied in the field of foam foaming, can solve the problems of easy static electricity, easy pollution and non-conformity in drying, and achieve the effects of ensuring excellent performance, improving noise absorption performance, and increasing areal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

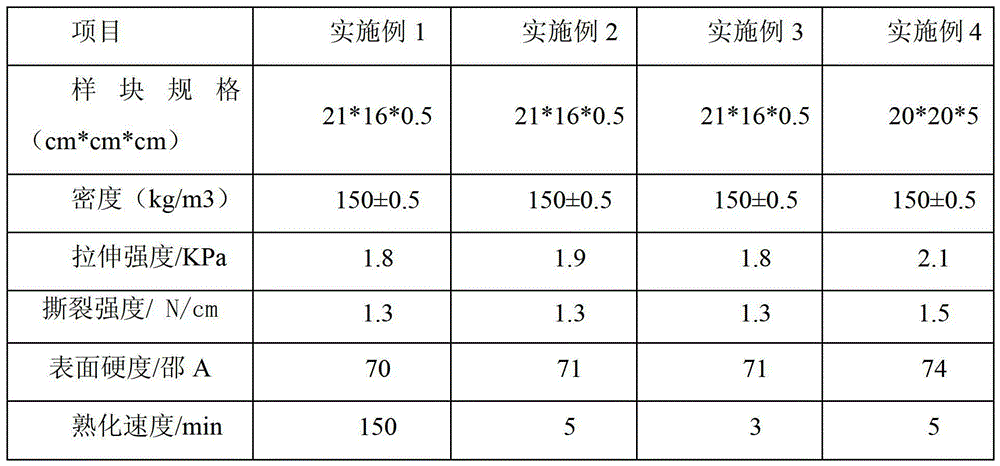

Examples

Embodiment 1

[0031] A component material:

[0032] Polyether polyol A: 70 (with glycerin as the initiator, primary hydroxyl content ≥ 70%, number average molecular weight 4000)

[0033] Polyether polyol B: 30 (ethylene glycol as the initiator, primary hydroxyl content ≥ 80%, number average molecular weight 3000)

[0034] AK7703: 0.8

[0035] DC-829: 0.3

[0036] Kaolin: 40

[0037] B component material:

[0038] Polyether polyol C: 50 (using ethylene glycol as the initiator, primary hydroxyl content ≥ 80%, number average molecular weight 2000)

[0039] 1,6 hexanediol: 3

[0040] Pure MDI: 15

[0041] Aggregated MDI: 10

[0042] Phosphoric acid: 10ppm

[0043] Preparation of component A materials: Put the measured polyether polyol A, polyether polyol B, AK7703, DC-829, and solid fillers into the reactor in sequence, set the speed at 60 rpm, and stir for 1 hour. Sampling is carried out for free bubble detection experiment. If milk white, gel, daily limit time and free bubble density...

Embodiment 2

[0047] A component material:

[0048] Polyether polyol A: 40 (with glycerin as the initiator, primary hydroxyl content ≥ 70%, number average molecular weight 5000)

[0049] Polyether polyol B: 40 (ethylene glycol as the initiator, primary hydroxyl content ≥ 80%, number average molecular weight 4000)

[0050] AK7703: 0.3

[0051] DC-829: 0.9

[0053] B component material:

[0054] Polyether polyol C: 10 (using ethylene glycol as the initiator, primary hydroxyl content ≥ 80%, number average molecular weight 3000)

[0055] 1,4-Butanediol: 5

[0056] Pure MDI: 45

[0057] Phosphoric acid: 10ppm

[0058] Preparation of component A materials: Put the measured polyether polyol A, polyether polyol B, AK7703, DC-829, and solid fillers into the reaction kettle in sequence, set the speed at 100 rpm, and stir for 1 hour. Sampling is carried out for free bubble detection experiment. If milk white, gel, daily limit time and free bubble density meet the desig...

Embodiment 3

[0062] A component material:

[0063] Polyether polyol A: 80 (with glycerin as the initiator, primary hydroxyl content ≥ 70%, number average molecular weight 7000)

[0064] Polyether polyol B: 0 (ethylene glycol as the initiator, primary hydroxyl content ≥ 80%, number average molecular weight 2000)

[0065] AK7703: 2.0

[0066] DC-829:1

[0068] B component material:

[0069] Polyether polyol C: 70 (using ethylene glycol as the initiator, primary hydroxyl content ≥ 80%, number average molecular weight 4000)

[0070] Ethylene glycol: 10

[0071] Carbodiimide modified MDI: 85

[0072] Phosphoric acid: 10ppm

[0073] Preparation of component A materials: Put the measured polyether polyol A, polyether polyol B, AK7703, DC-829, and solid fillers into the reactor in sequence, set the speed at 60 rpm, and stir for 2 hours. Sampling is carried out for free bubble detection experiment. If milk white, gel, daily limit time and free bubble density mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com