Production method of slow-release chelated compound fertilizer containing multiple elements

A technology of compound fertilizer and production method, applied in fertilizer mixture, fertilization device, application and other directions, can solve problems such as difficulty in granulating humic acid, and achieve the effects of low cost, improved density and strength, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

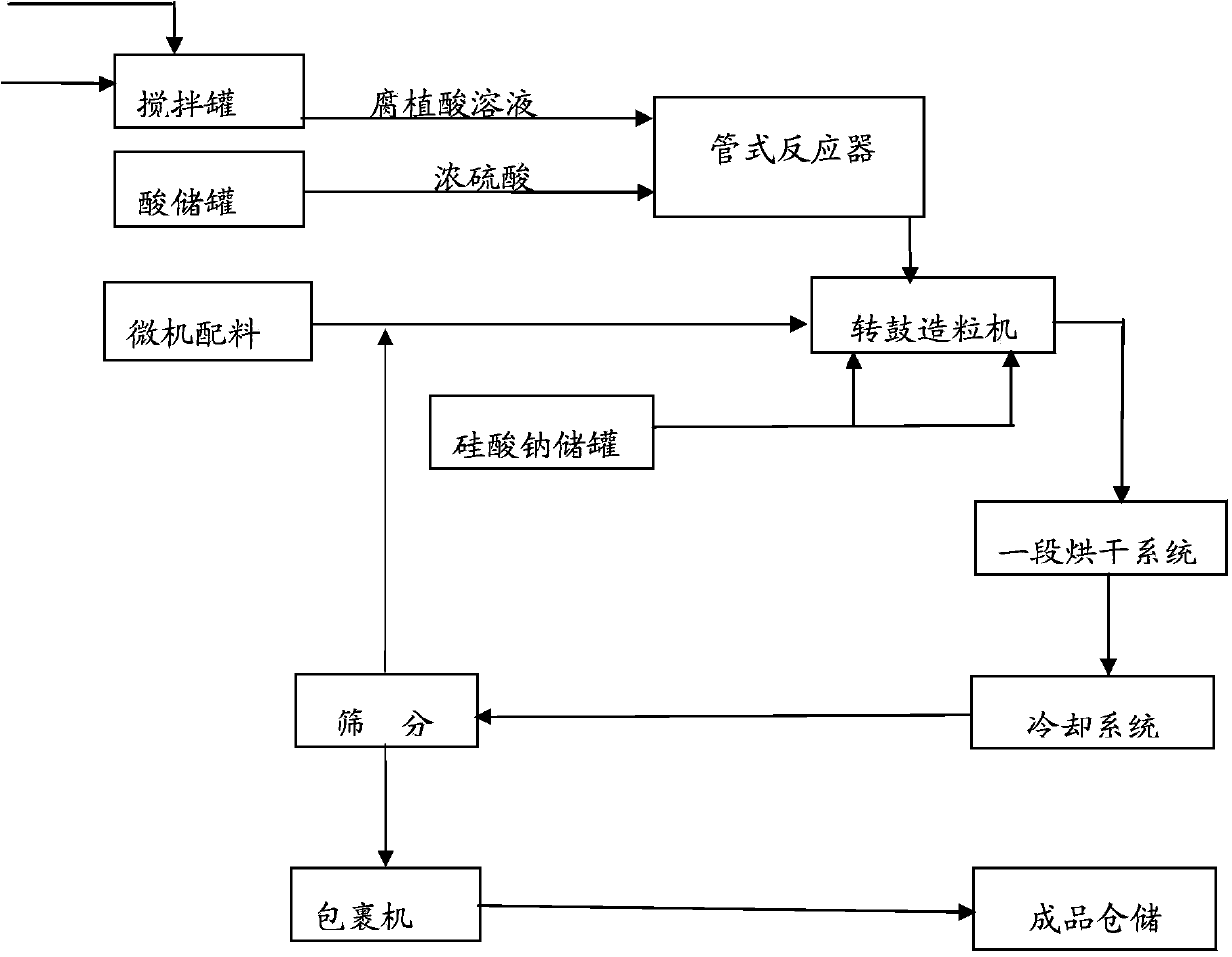

Image

Examples

Embodiment 1

[0048] Embodiment 1: 15%-10%-10% conventional products

[0049] Mix 90 kg of humic acid (mass percentage, the same below, containing 65% organic matter) in a mixing tank with water to make a humic acid solution with a mass percentage concentration of 40%, pump it into the tubular reactor after metering At the same time, 60 kg of concentrated sulfuric acid (containing S31.5%) with a concentration of 98% is pumped into the tubular reactor after metering to make a mixed solution of humic acid and sulfuric acid at about 85°C, and at the same time, it is metered into the 260 kg of urea (containing N46.2%), 183 kg of powdered monoammonium phosphate (containing N11%, P2O545%), potassium chloride (containing K 2O60%) 170 kg, ammonium chloride (containing N25.2%) 30 kg, ordinary calcium superphosphate (containing P2O517%, Ca10.5%) 110 kg, magnesium oxide (containing Mg60%) 40 kg, liquid sodium silicate (containing Si26%) 35 kg, zinc sulfate (containing S16.5%, Zn35%) 20 kg, the above ...

Embodiment 2

[0050] Embodiment 2: 12%-8%-20% high potassium product

[0051] Mix 80 kg of humic acid (mass percentage, the same below, containing 65% organic matter) in a mixing tank with water to make a humic acid solution with a mass percentage concentration of 40%, pump it into the tubular reactor after metering At the same time, 50 kg of concentrated sulfuric acid (containing S31.5%) with a concentration of 98% is pumped into the tubular reactor after metering to make a mixed solution of humic acid and sulfuric acid at about 80°C, and at the same time, it is metered into the 230 kg of urea (containing N46.2%), 140 kg of powdered monoammonium phosphate (containing N11%, P2O545%), 335 kg of potassium chloride (containing K2O60%), 100 kg of ordinary calcium superphosphate (containing P2O517%, Ca10 .5%), 30 kg of magnesium oxide (containing Mg60%), 30 kg of liquid sodium silicate (containing Si26%), 10 kg of zinc sulfate (containing S16.5%, Zn35%), the above materials are sprayed with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cumulative release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com