Brake control method of electric tool

A brake control and electric tool technology, applied in the electric tool brake (commonly known as brake) control, electric tool control field, can solve the field effect tube heating, shorten the service life of the device, start and stop, frequent reversing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

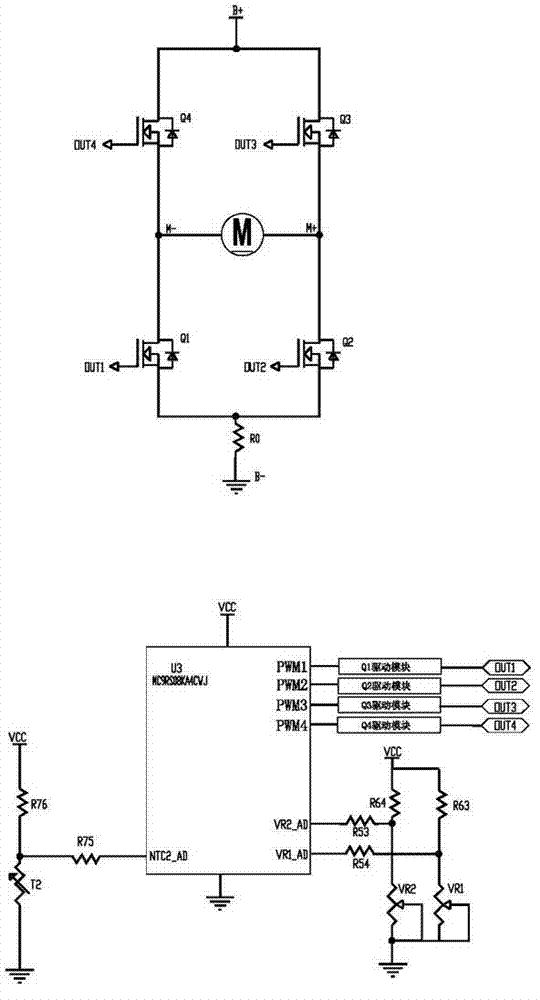

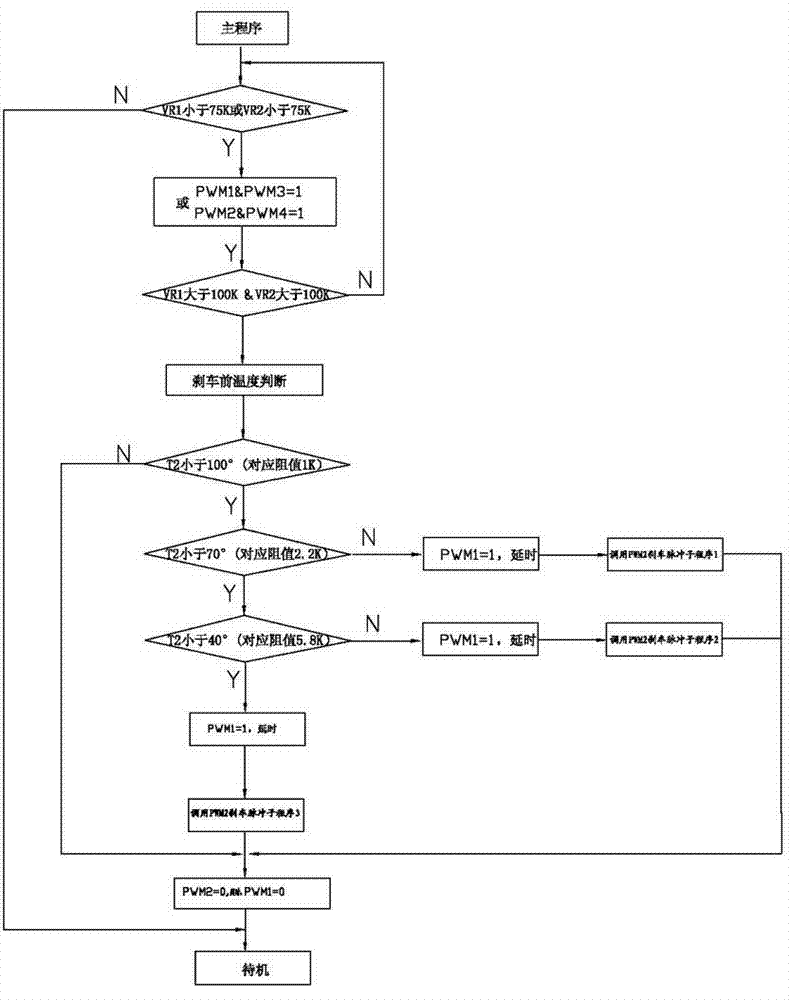

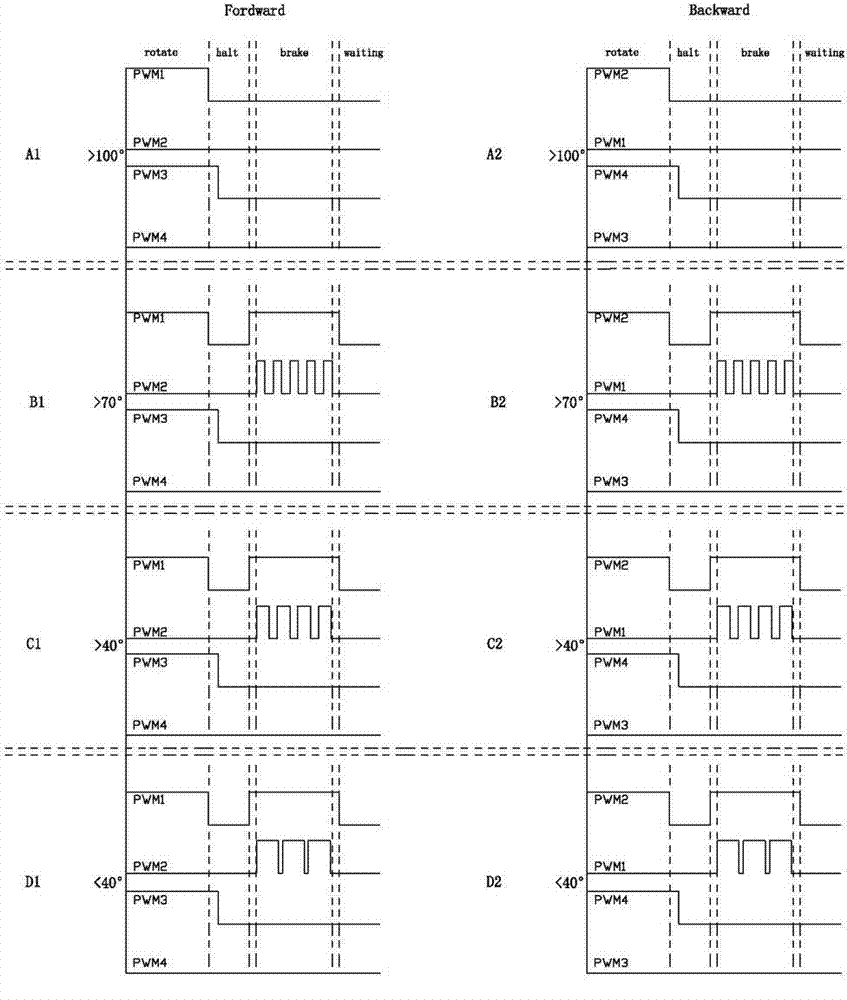

[0023] The power tool in this embodiment is an electric drill (see 201210262057.x), which contains figure 1 In the circuit shown, the positive pole B+ of the power supply passes through the forward-rotating front-end field effect transistor Q3, passes through the positive pole M+ of the motor to the negative pole M-, and then connects the forward-rotating rear field effect transistor Q1 to the negative pole B- of the power supply to form a forward-rotating drive circuit. The positive pole B+ passes through the reverse front field effect transistor Q4, passes through the negative pole M- of the motor to the positive pole M+, and then connects the reverse field effect transistor Q2 to the negative pole B- of the power supply to form a reverse drive circuit. The controlled terminals PWM1-PWM4 of each FET are respectively connected to the driving output terminals of the corresponding control signals of the microprocessor U3 in the control circuit. The two switch signal input termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com