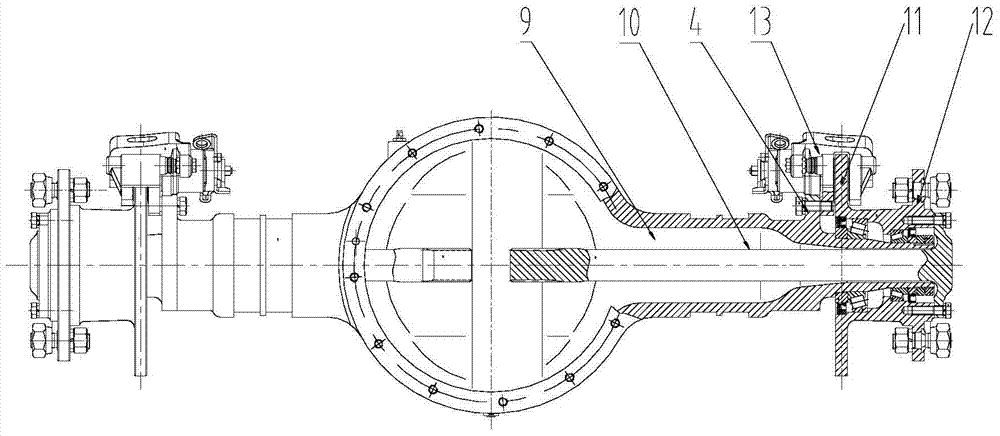

Forklift drive axle with disc brakes installed

A technology of disc brakes and drive axles, applied in the directions of brakes, brake components, axles, etc., can solve the problems of difficult clearance, walking with brakes, and easy locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

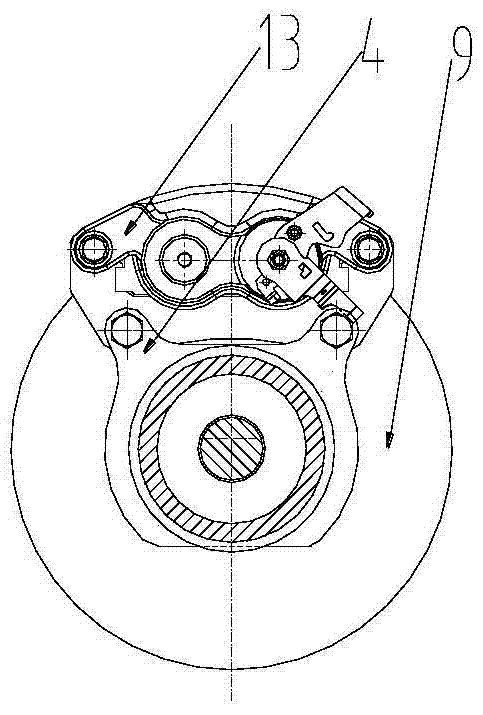

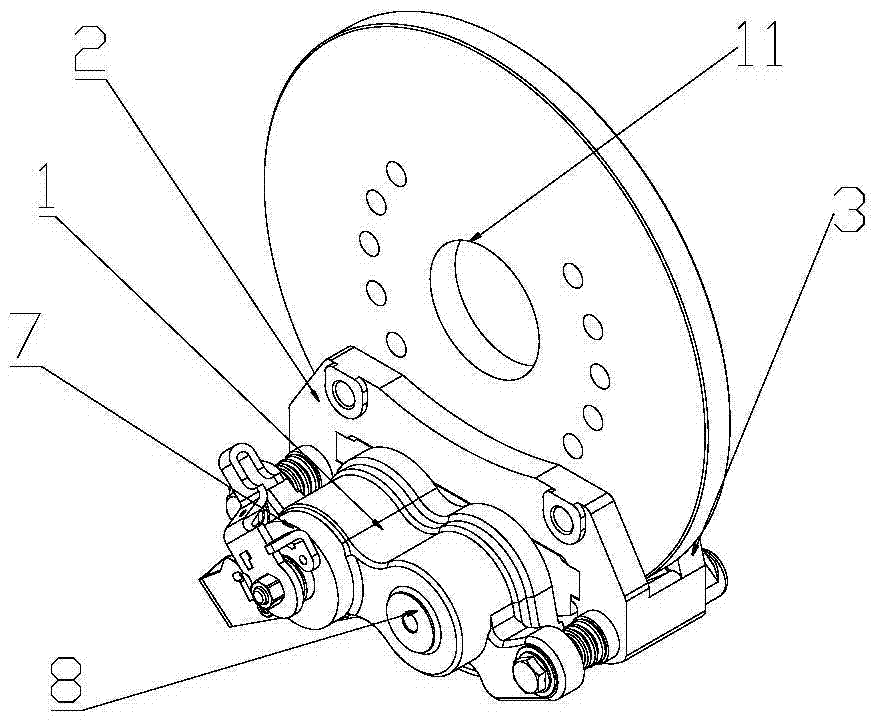

[0023] refer to figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, a forklift drive axle equipped with disc brakes includes a forklift axle housing 9 and a half shaft 10 crossing the forklift axle housing 9, and brake discs are installed at both ends of the forklift axle housing 9 from the inside to the outside. 11 and the wheel hub 12, the forklift axle housing 9 is equipped with a disc brake 13 corresponding to the brake disc 11. The disc brake 13 includes a caliper body 1, a driving mechanism arranged in the caliper body 1, and an inner wheel driven by the driving mechanism. The friction plate 2 and the outer friction plate 3 fixedly arranged on the caliper body 1 and opposite to the inner friction plate 2 , and the brake disc 11 is arranged between the inner friction plate 2 and the active surface of the outer fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com