Partial air cooling method for precast aperture passage in investment casting shell

An investment casting, partial technology, applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of poor controllability of cooling range and cooling rate, achieve high controllability of cooling range and increase local cooling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

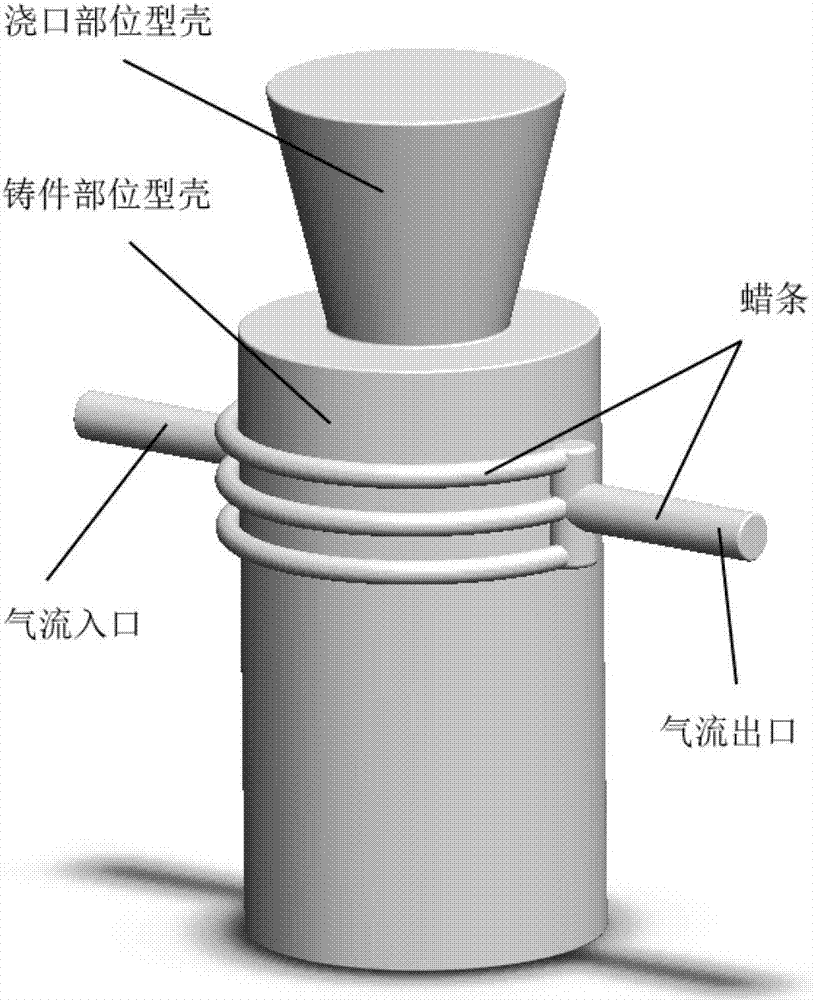

[0018] First, press the wax mold and weld the gating system according to the normal investment casting process, and then proceed to the shell making process. When the shell-making process has reached a certain number of layers and the shell has established a certain strength, as shown in the attached figure, stick wax strips on the parts of the casting that need to be cooled quickly, first bake the wax strips to soften them, and then Press on the surface of the shell to make it stick to the surface of the shell, melt a small amount of adhesive wax and drop it on the gap between the wax strip and the shell to fix the wax strip on the surface of the shell. According to the shape and size of the part to be cooled, one or more wax strips can be pasted, and the specific arrangement of the wax strips can be determined according to the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com