Anisotropic conductive film, method for producing bonded body, and bonded body

An anisotropic, conductive film technology, applied in the direction of conductive connection, printed circuit manufacturing, conductive adhesive connection, etc., can solve the problem of high connection resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115]

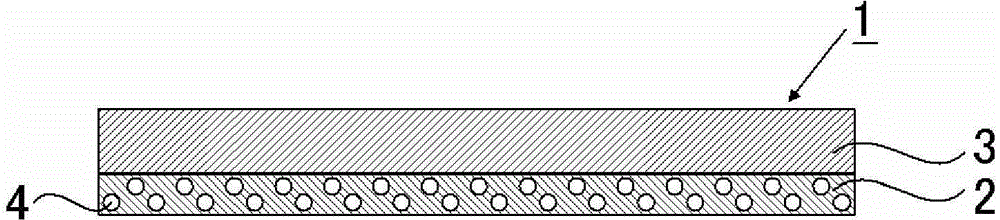

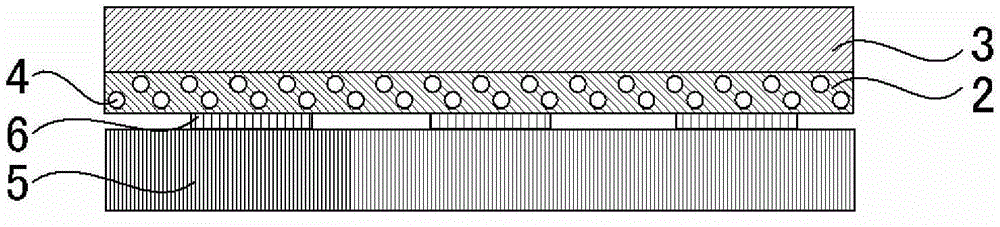

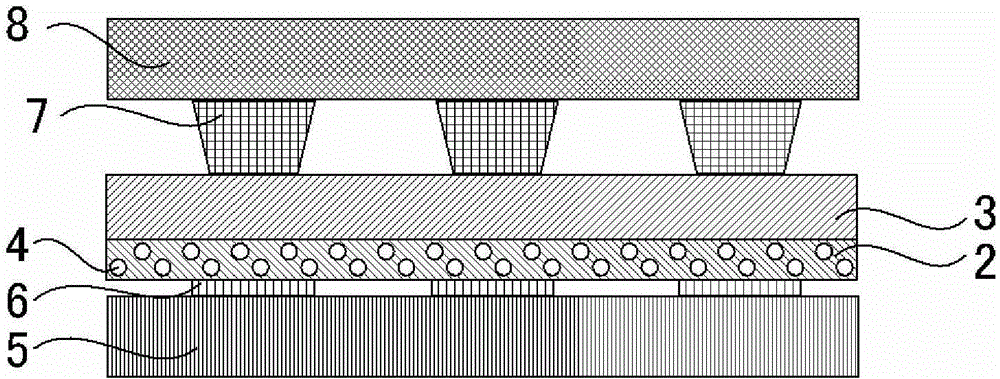

[0116] -Formation of conductive particle-containing layer-

[0117] 60 parts by mass of phenoxy resin (trade name: YP50, manufactured by Nippon Steel Chemical Co., Ltd.), 35 parts by mass of acrylic resin (trade name: EB-600, manufactured by Daicel Cytec Corporation), silane coupling agent (trade name : KBM-503, manufactured by Shin-Etsu Chemical Co., Ltd.) 2 parts by mass, polymerization initiator (trade name: Perhekisa C, 1,1-bis(tert-butylperoxy)cyclohexane, manufactured by NOF Corporation) 1 mass In the binder composed of parts, the particle density is 8,000 / mm 2 Conductive particles (trade name: AUL704, manufactured by Sekisui Chemical Co., Ltd.) were dispersed by the method. The dispersed complex was applied to peel-treated PET so that the average thickness after drying was 8 μm, to prepare a conductive particle-containing layer.

[0118] -Production of insulating adhesive layer-

[0119] 60 parts by mass of phenoxy resin (trade name: YP70, manufactured by ...

Embodiment 2

[0137]

[0138] Except that the polymerization initiator (trade name: パヘキサC, 1,1-bis(tert-butylperoxy)cyclohexane, manufactured by NOF Corporation) containing the conductive particle layer in Example 1 was changed to 3 parts by mass. Except that, it carried out similarly to Example 1, and obtained the anisotropic conductive film.

[0139] The same evaluation as in Example 1 was performed. Table 1-1 shows the results.

Embodiment 3

[0141]

[0142] Except that the polymerization initiator (trade name: パヘキサC, 1,1-bis(tert-butylperoxy)cyclohexane, manufactured by NOF Corporation) containing the conductive particle layer in Example 1 was changed to 8 parts by mass. Except that, it carried out similarly to Example 1, and obtained the anisotropic conductive film.

[0143] The same evaluation as in Example 1 was performed. Table 1-1 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com