Light emitting device, illuminating system, and illuminating method

A light-emitting device and lighting system technology, applied in the direction of lighting devices, electroluminescent light sources, lighting and heating equipment, etc., can solve the problem of complex calculation steps of driving current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0161] (Structure of light emitting part)

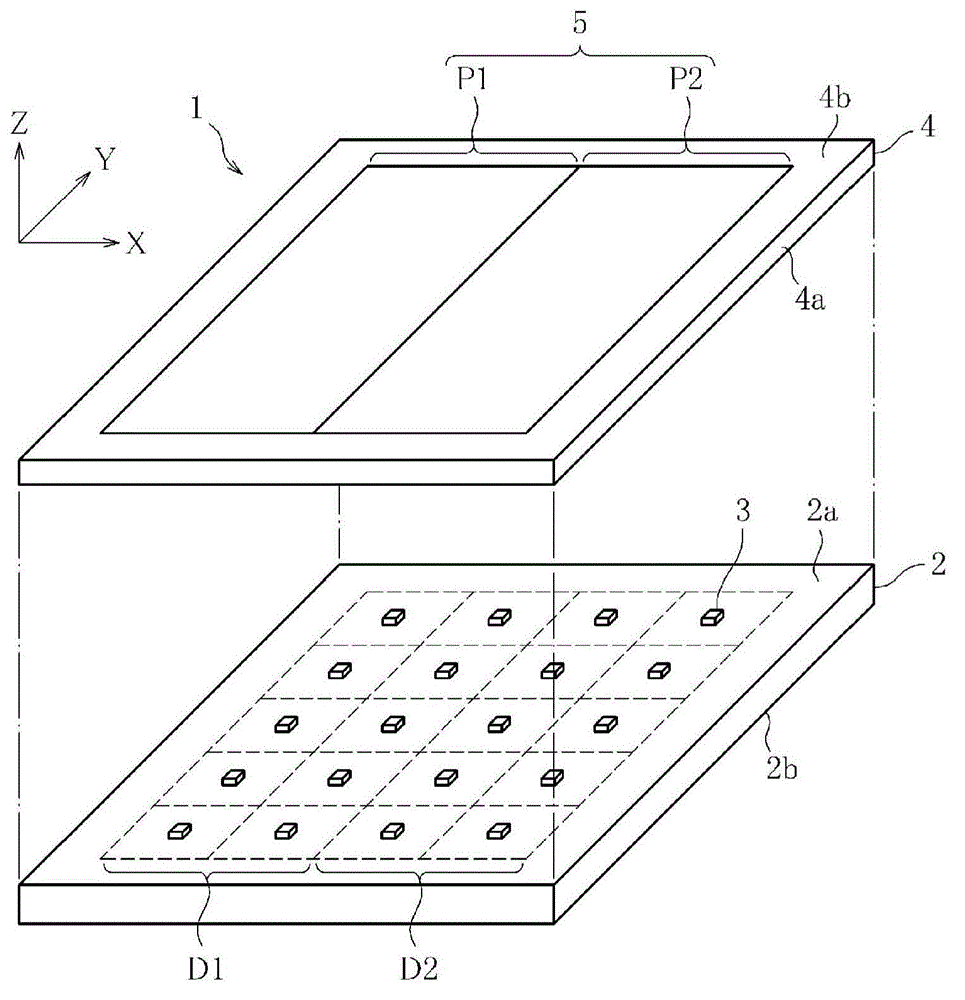

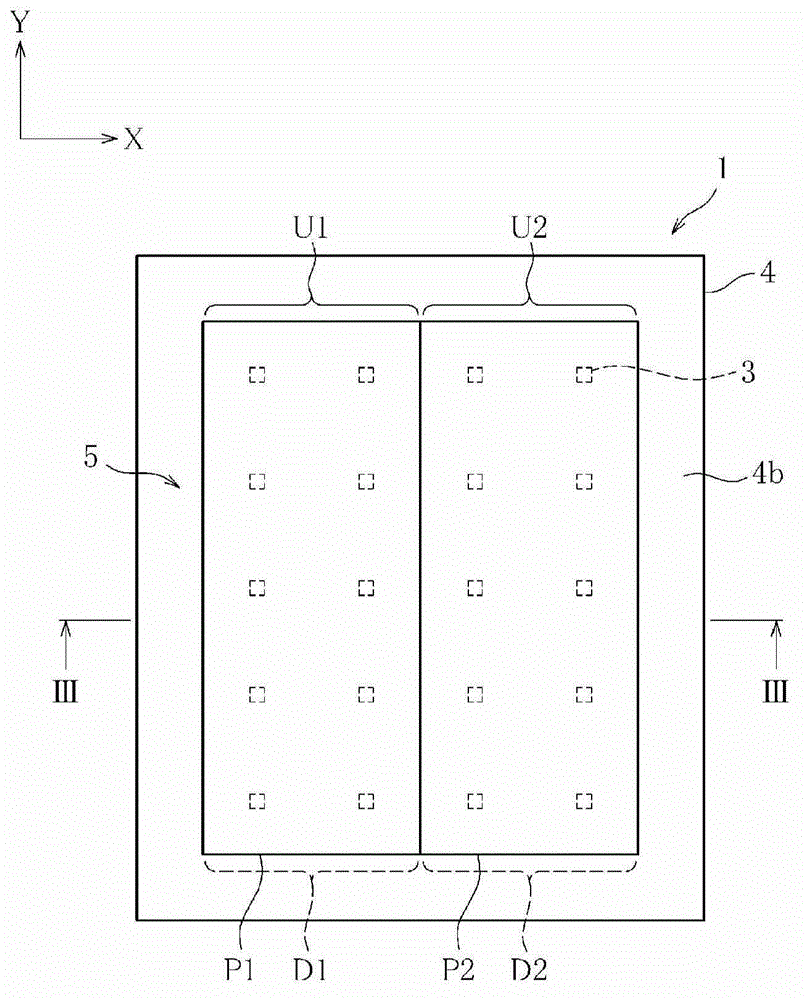

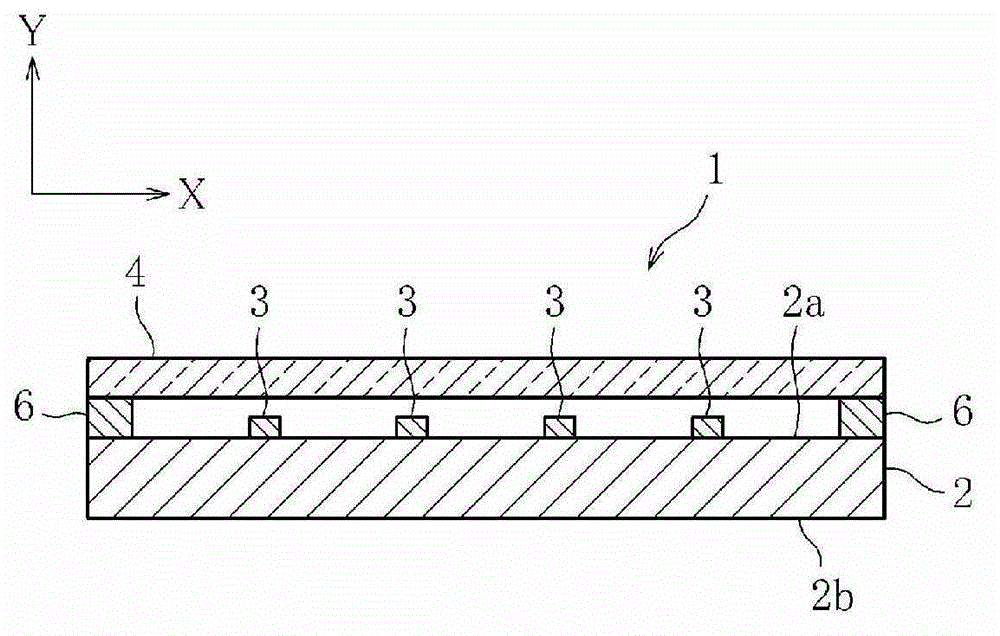

[0162] figure 1 It is a perspective view schematically showing the overall structure of the light emitting unit 1 in the light emitting device (illumination device) of this embodiment, figure 2 yes figure 1 The top view of the light-emitting part 1. In addition, in figure 1 and figure 2 In , the width direction of the light emitting part 1 is defined as the X direction, the length direction is defined as the Y direction, and the height direction is defined as the Z direction. Such as figure 1 As shown, the light emitting unit 1 includes a wiring board 2 made of alumina-based ceramics that is excellent in electrical insulation and has good heat dissipation. On the chip mounting surface 2a of the wiring substrate 2, four chips are arranged at equal intervals in the width direction of the wiring substrate 2 (that is, the X direction), and five chips are arranged at equal intervals in the longitudinal direction (that is, the Y di...

no. 2 Embodiment >

[0257] In the first embodiment described above, the fluorescent member 5 is constituted by the first wavelength conversion region P1 and the second wavelength conversion region P2 that emit primary light having different color temperatures. That is, two types of primary light having different color temperatures are emitted from the fluorescent member 5 . However, various changes and substitutions can be made without departing from the gist of the present invention. Therefore, hereinafter, as a second embodiment of the present invention, a light emitting unit 1', a light emitting device 11', and a lighting system using a fluorescent member 5' having a structure different from that of the fluorescent member 5 of the first embodiment will be described. A case of 12'. In addition, the same reference numerals are assigned to the same components and structural parts as those of the first embodiment, and their descriptions are omitted.

[0258] (Structure of light emitting part)

...

no. 3 Embodiment >

[0304] In the first embodiment described above, the fluorescent member 5 is constituted by the first wavelength conversion region P1 and the second wavelength conversion region P2 that emit primary light having different color temperatures. That is, two types of primary light having different color temperatures are emitted from the fluorescent member 5 . However, various changes and substitutions can be made without departing from the gist of the present invention. Therefore, in the following, as a third embodiment of the present invention, a light emitting unit 1", a light emitting device 11" and a lighting system using a fluorescent member 5" having a structure different from that of the fluorescent member 5 of the first embodiment will be described. 12" example. In addition, the same reference numerals are assigned to the same components and structural parts as those of the first embodiment, and their descriptions are omitted.

[0305] (Structure of light emitting part) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com