Method for detecting repetitive defects of semiconductor devices

A detection method and semiconductor technology, which is applied in the direction of semiconductor/solid-state device testing/measurement, can solve problems such as undetectable, and achieve the effect of guaranteeing manufacturing and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

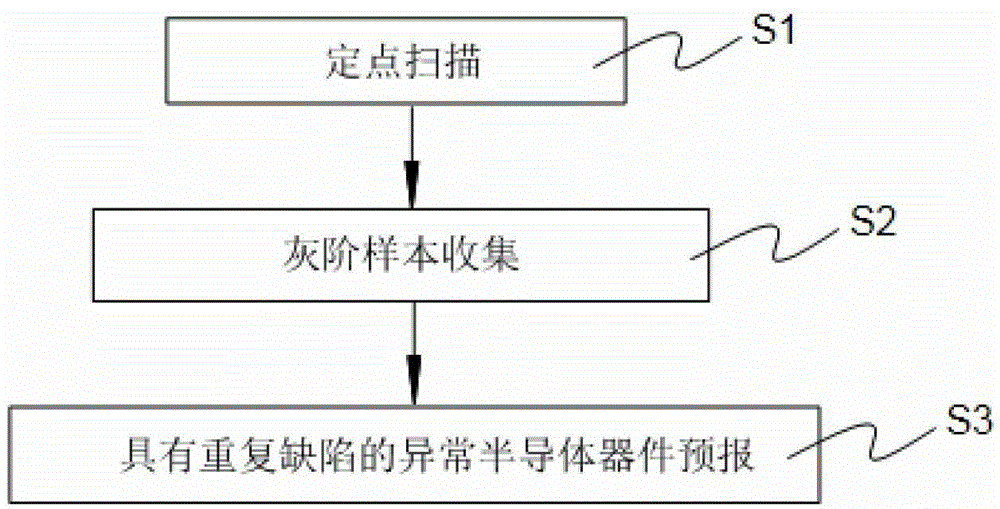

[0029] see figure 1 , figure 1 Shown is a flow chart of the detection method of the repetitive defect of the semiconductor device of the present invention. The method for detecting repetitive defects of the semiconductor device includes the following steps:

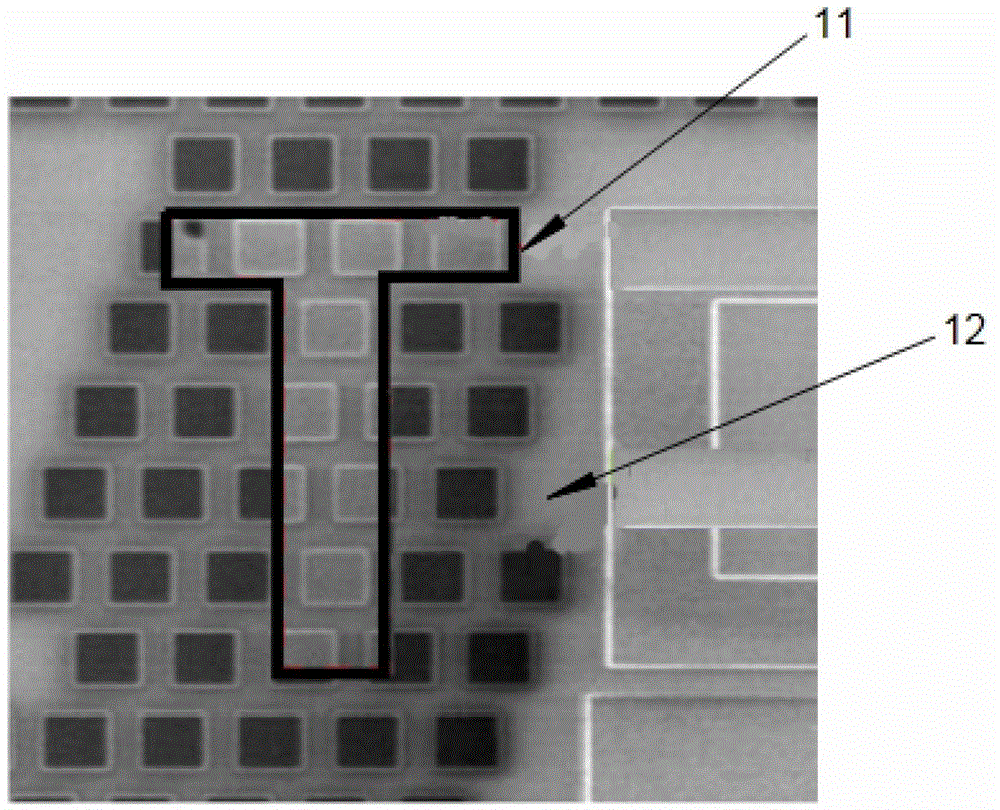

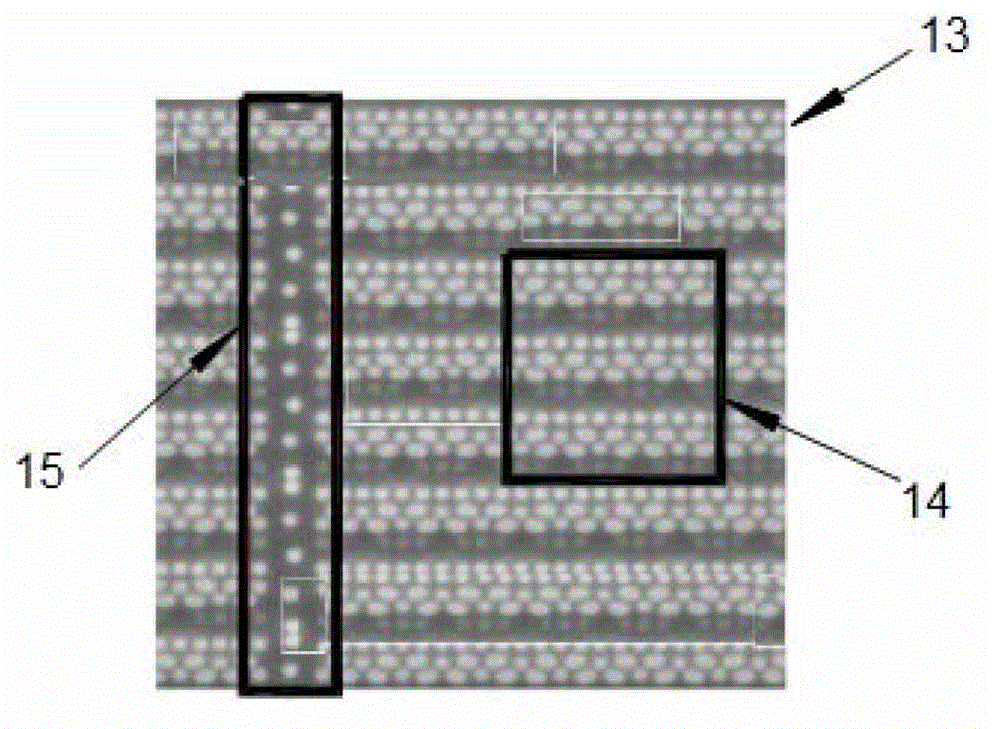

[0030] Executing step S1: fixed-point scanning; specifically, the fixed-point scanning further includes, using an electron beam defect scanner to establish a fixed-point scanning program on the metal connection layer of a semiconductor device using a normal process, and selecting the internal area of the repeating unit in the module to be tested , taking the smallest area that can be scanned by the electron beam defect scanner as a scanning unit area, the scanning unit area is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com