Test method for reliability of polymer battery

A test method and polymer technology, applied in the direction of machine/structural component testing, impact testing, measuring electricity, etc., to achieve the effect of evaluating reliability, good reliability, and simple and reliable testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

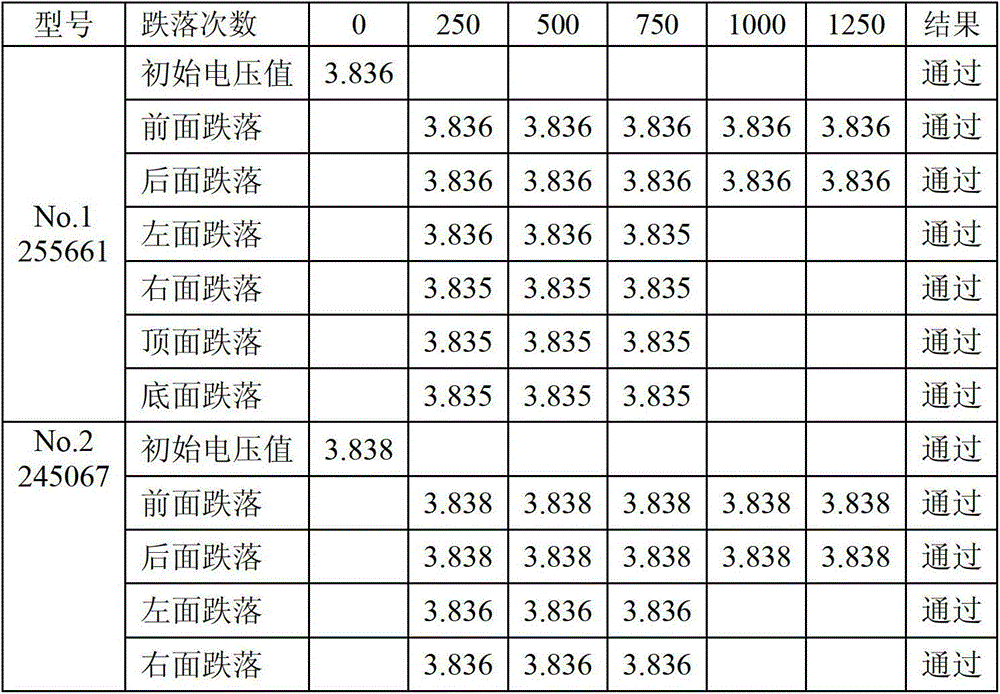

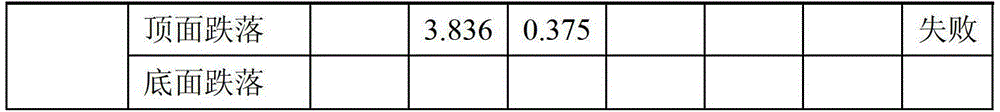

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0018] The reliability test method of polymer battery of the present invention includes the following steps:

[0019] 1) Measure and record the initial voltage and initial internal resistance of the polymer battery to be tested; the battery used in the drop test is generally half or full.

[0020] 2) The polymer battery is fixedly arranged in the corresponding battery slot of the test box and the tabs of the polymer battery are insulated, wherein the polymer battery is kept at a distance of more than 2mm from the inner sides of the groove; specifically ,Fix the polymer battery in the designed test box with strong double-sided tape to ensure that the package shell of the polymer battery and the test box do not move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com