Method for converting ferulic acid to produce vanillin by immobilized amycolatopsis

A technology of Amycolatopsis and ferulic acid, applied in the field of bioengineering, can solve the problems of low conversion rate of ferulic acid, low production efficiency, high production cost, etc., and achieve continuous production, low cost and high production cost. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

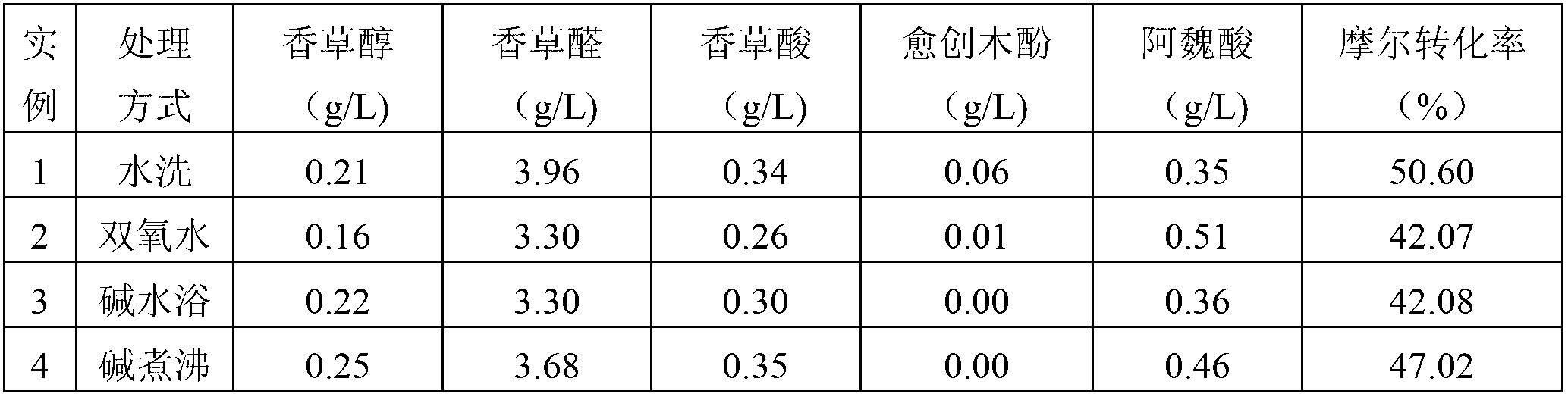

[0021] Example 1-4, the situation of vanillin produced by immobilized cells prepared from sawdust with different treatment methods

[0022] Sawdust is processed as follows: soak and rinse with clean water, H 2 O 2 Treatment; NaOH water bath; NaOH boiling. Take a ring of bacterial lawn from the preservation slant and inoculate it into the seed medium, the composition of the seed medium: glucose 5g; yeast extract 5g; Na 2 HPO 4 ·12H 2 O4g; KH 2 PO 4 1g; NaCl0.2g; MgSO 4 ·7H 2 O0.2g; CaCl 2 2H 2 O0.05g; dilute to 1L with tap water, adjust the pH to 7.2, and fill in a 30mL / 250mL triangular flask. Cultivate in a constant temperature shaker at 30°C and 200r / min for 24 hours; inoculate the seeds into the cell expansion medium with an inoculum of 8% (the composition of the expansion medium is the same as that of the seed medium, and the liquid volume is 50mL / 500mL Erlenmeyer flask), Expand culture at 37°C and 200r / min for 24h, add 10g of treated sawdust, continue to cultiva...

Embodiment 5-9

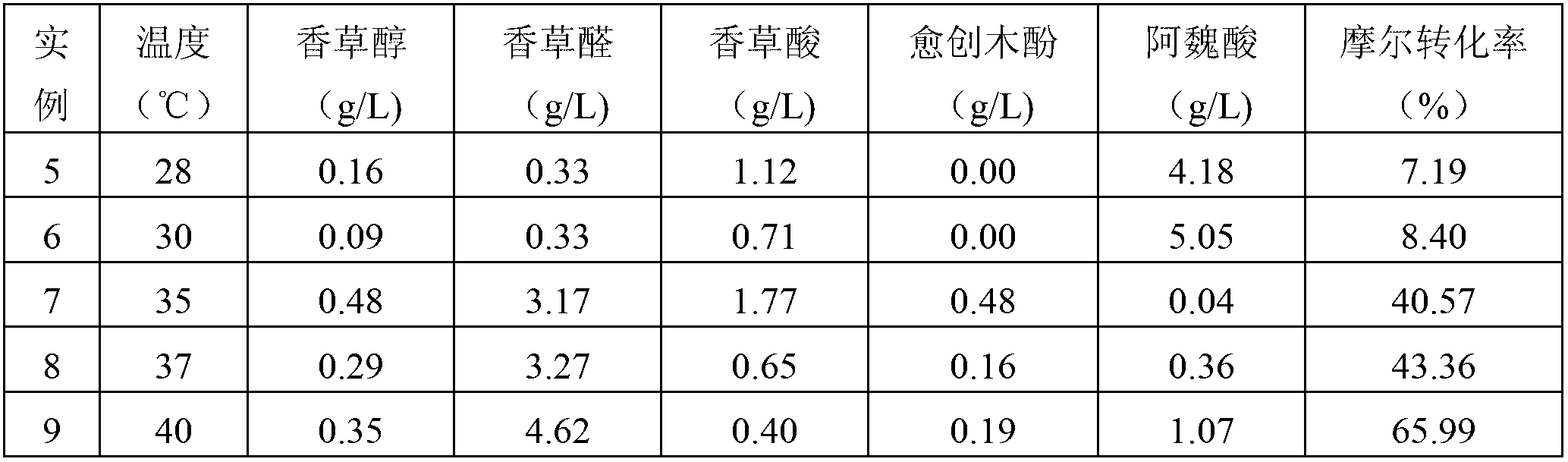

[0025] Embodiment 5-9 temperature produces vanillin situation to immobilized cell transformation

[0026] Immobilized cells were prepared according to the method in Example 1, and transformed at different transformation temperatures: 28°C, 30°C, 35°C, 37°C, and 40°C. The results are shown in Table 2:

[0027] Table 2 The influence of temperature on the production of vanillin by transformation of immobilized cells

[0028]

[0029] The conversion reaction is carried out at 35-40°C.

Embodiment 10

[0030] Example 10 Reuse of immobilized cells

[0031] Prepare immobilized cells according to the method of Example 1, the substrate ferulic acid concentration of the transformation reaction is 10g / L, the initial transformation pH is 9.0, the transformation temperature is 40°C, the shake flask rotation speed is 200rpm, the transformed immobilized cells are filtered, and repeated Use, see Table 3 for each result:

[0032] Table 3 Reuse of immobilized cells

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com