Making method of ceramide and/or glucosylceramide generation accelerator

A technology of ceramide and manufacturing method, applied in the field of ceramide and/or glucosylceramide production accelerator, to achieve the effect of improving moisturizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (Manufacture of ceramide and / or glucosylceramide production promoter)

[0049] As a microorganism for producing ceramide and / or glucosylceramide production accelerator from bean dregs, Brettanomyces claussenii (purchased from Jiangnan University and deposited in CICIM, China Universities Industrial Microbiology Resources and Information Center, deposit No. CICIM Y0125).

[0050] Inoculate the above strain obtained by culturing in YPD (Yeast Extract Peptone Dextrose Medium) medium at 30°C into a Erlenmeyer flask (capacity 300ml) containing 100ml of ceramide / glucosylceramide production promoter production medium, and inoculate at 30°C cultured for 72 hours. The medium contained 10 w / v% okara and 1 w / v% glucose. Wherein, the preparation of soybean dregs is obtained by soaking soybeans in water for 12 hours to make soybeans fully absorb water, then grinding and crushing the soybeans that have absorbed water, filtering and removing liquid components, and draining remaining...

Embodiment 2

[0054] As a microorganism for producing ceramide / glucosylceramide production accelerator from bean dregs, Brettanomyces claussenii (purchased from Jiangnan University and deposited in CICIM, China Universities Industrial Microbiology Resources and Information Center, accession number CICIMY0251 ). The same method as in Example 1 was used to obtain the okara fermented extract as the ceramide / glucosylceramide production accelerator of the present invention.

[0055] Furthermore, this okara fermented extract was dissolved in 50v / v% ethanol, adjusted to a concentration of 0.1w / v% (product B of the present invention), stored at 4°C, and used for the subsequent promotion of ceramide / glucosylceramide production test.

Embodiment 3

[0057] As a microorganism for producing ceramide / glucosylceramide production accelerator from bean dregs, Brettanomyces claussenii (purchased from Jiangnan University and deposited in CICIM, China Universities Industrial Microbiology Resources and Information Center, accession number CICIM Y0127). The same method as in Example 1 was used to obtain the okara fermented extract as the ceramide / glucosylceramide production accelerator of the present invention.

[0058] Furthermore, the okara fermented extract was dissolved in 50v / v% ethanol, and the concentrations were adjusted to 1w / v% (invention product C) and 0.1w / v% (invention product D), respectively, and stored at 4°C , used in the subsequent ceramide / glucosylceramide production promotion test.

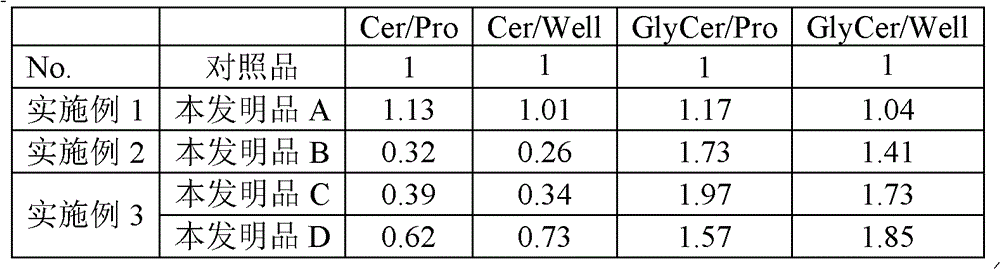

[0059] (Ceramide / glucosylceramide production promotion test)

[0060]

[0061] First, normal human activated keratinocytes (Cascade Co., Ltd) were used as primary cells, and placed in a 75cm 2 In a culture flask (2ml of culture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com