Method for producing low freezing point diesel oil by coked gasoline and diesel oil

A gasoline, diesel and diesel technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of small freezing point depression and low cetane number of diesel oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

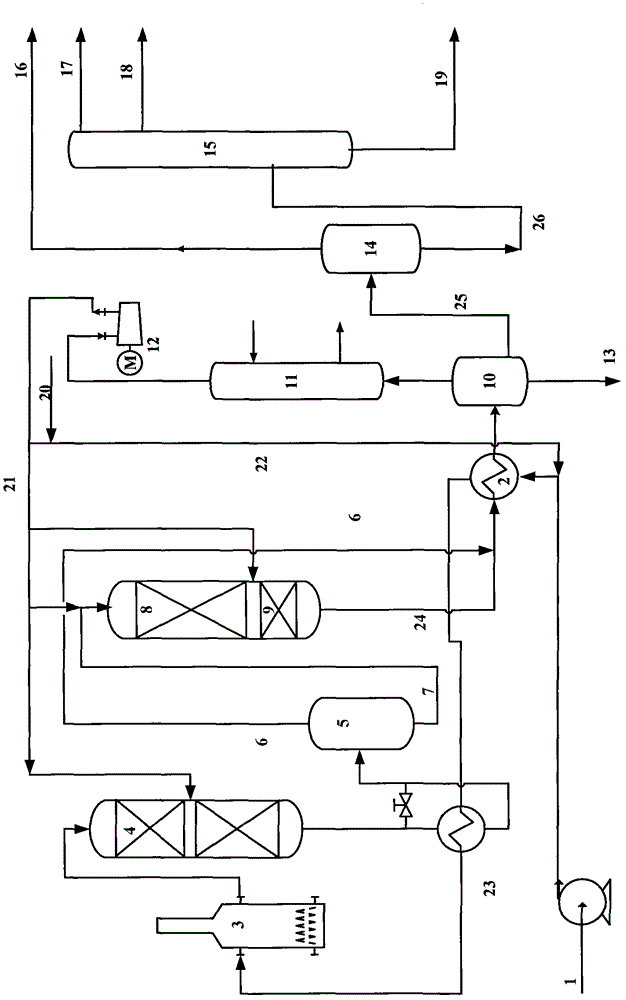

Image

Examples

Embodiment 1

[0059] Using a kind of coking gasoline and diesel mixed oil A as raw material, the raw material A is firstly subjected to whole-distillate hydrotreating in the first reaction zone, and the reaction effluent passes through a hot high-pressure separator and is flashed into two parts: a gas phase stream and a liquid phase stream , the liquid phase stream is mixed with hydrogen and then enters the second reaction zone for decondensation and post-refining reactions. The hydrofinishing catalyst I loaded in the first reaction zone is RS-1000, the hydrotreating catalyst D loaded in the second reaction zone is RS-1000, and the hydrofining catalyst II loaded in the second reaction zone is RS-1000. The filling volume ratio is: 50:40:10. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 2. The thermal high-resolution operating conditions are: 4.0MPa, 355°C.

[0060] It can be seen from the data in Table 2 that under m...

Embodiment 2

[0065] Coking gasoline and diesel mixed oil A is used as raw material, treated by the method provided by the present invention, using hydrofinishing catalyst I (RS-1000), hydromodified decondensation catalyst D and hydrofinishing catalyst II (RS-1000) , the three-part catalyst loading ratio is 45:45:10, the operating pressure of the hot high-pressure separator is 8.0MPa, and 350°C. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 2.

[0066] It can be seen from the data in Table 2 that the freezing point of the diesel product was reduced to -27°C, the cold filter point was reduced to -16°C, the yield reached 93.5%, the cetane number increased to 51.8, and the sulfur content was greatly reduced.

Embodiment 3

[0068] Coking gasoline and diesel mixed oil B is used as raw material, processed by the method provided by the present invention, using hydrofinishing catalyst I (RS-1000), hydromodified decondensation catalyst D and hydrofinishing catalyst II (RS-1000) , the three-part catalyst loading ratio is 40:50:10, the operating pressure of the hot high-pressure separator is 6.4MPa, and 355°C. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 3.

[0069] It can be seen from the data in Table 3 that the freezing point of the diesel product was reduced to -45°C, the cold filter point was reduced to -33°C, the yield reached 85.4%, the cetane number increased to 48.1, and the sulfur content was greatly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com