Start-up presulfidation method of hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, which is applied in the petroleum industry, hydrocarbon oil cracking, etc., can solve the problems of difficulty in ensuring the oxidation state, cracking activity and activity stability of elemental metal catalysts, low decomposition temperature, and high relative density, and achieve saving manpower, increase the concentration of hydrogen sulfide, avoid the effect of emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

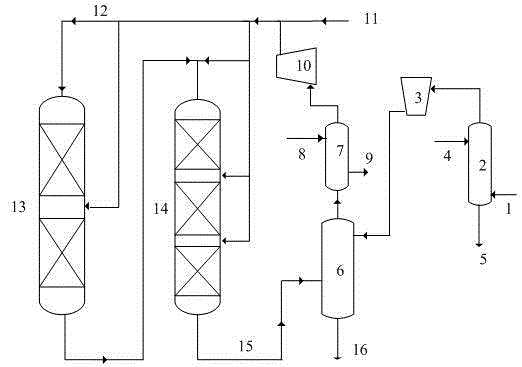

[0034] Such as figure 1 As shown, an embodiment of the hydrogenation catalyst start-up method of the present invention is as follows:

[0035] Raise the inlet temperature of the refining reactor 13 to 170-190°C. Sulfur-containing exhaust gas 1 passes through light hydrocarbon absorption tower 2 for light hydrocarbon recovery, absorbing liquid heavy naphtha 4 is injected into the top of the tower, mixed naphtha 5 is discharged from the bottom of the tower to analyze and stabilize the system, and the absorbed gas is injected into the In high pressure separator 6. Then the obtained high-fraction gas is adjusted by hydrogen sulfide through the circulating hydrogen desulfurization tower 7, the top of the tower is injected with lean amine liquid 8, and the bottom of the tower is discharged with rich amine liquid 9, and the concentration of hydrogen sulfide is controlled at 0.5-1.5v% by washing, and then mixed with new hydrogen 11 is mixed to obtain mixed hydrogen 12, which enters ...

Embodiment 1

[0037] The properties of the catalysts used in Examples 1, 2 and Comparative Examples 1, 2 are listed in Table 1. The catalyst is a commercial catalyst developed and produced by Fushun Petrochemical Research Institute, wherein Example 1 and Example 2 are the start-up method of the present invention, Comparative Example 1 is a conventional dry start-up process, and Comparative Example 2 is the use of acidic acid rich in inert gas in a refinery. Air-drying start-up process.

[0038] Table 1 Main physicochemical properties of catalysts

[0039] project FF-36 FC-14 Chemical composition, wt% Mo-Ni W-Ni NiO 4.0 5.5 MoO 3 25.0 — WO 3 — 22.0 physical properties Appearance shape Clover Strips Cylindrical bar Crushing strength, N / cm ≥180 >185

[0040] Example 1

[0041] After the hydrogen airtightness of the hydrocracking unit is qualified, adjust the inlet pressure of the reaction system to 14.0MPa, start to...

Embodiment 2

[0043] After the hydrogen airtightness of the hydrocracking unit is qualified, adjust the inlet pressure of the reaction system to 12.0MPa, start to raise the temperature at 20°C / h, and when it reaches 170°C, pass the mixed acid gas into the light hydrocarbon absorption system for absorption, and then start the sulfidation The hydrogen compressor injects the absorbed gas into the high fraction, and the high fraction gas first passes through the circulating hydrogen desulfurization tower, and then enters the reaction system through the compressor. Adjust the operation of the circulating hydrogen desulfurization tower to control the H in the circulating hydrogen 2 The S concentration is 0.8v%, and when the hydrogen sulfide concentration at the outlet of the hydrocracking reactor reaches 0.11v%, it is considered that the hydrogen sulfide has penetrated the catalyst bed. Adjust the catalyst bed temperature to 230°C and keep the temperature constant for 8 hours. This process adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com