Method for preparing jet fuel blending component by using animal and vegetable oils as raw materials

A jet fuel, animal and vegetable oil technology, applied in the field of preparation of jet fuel blending components, can solve problems such as atmospheric environmental pollution, achieve high calorific value, clear and transparent appearance, and low freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

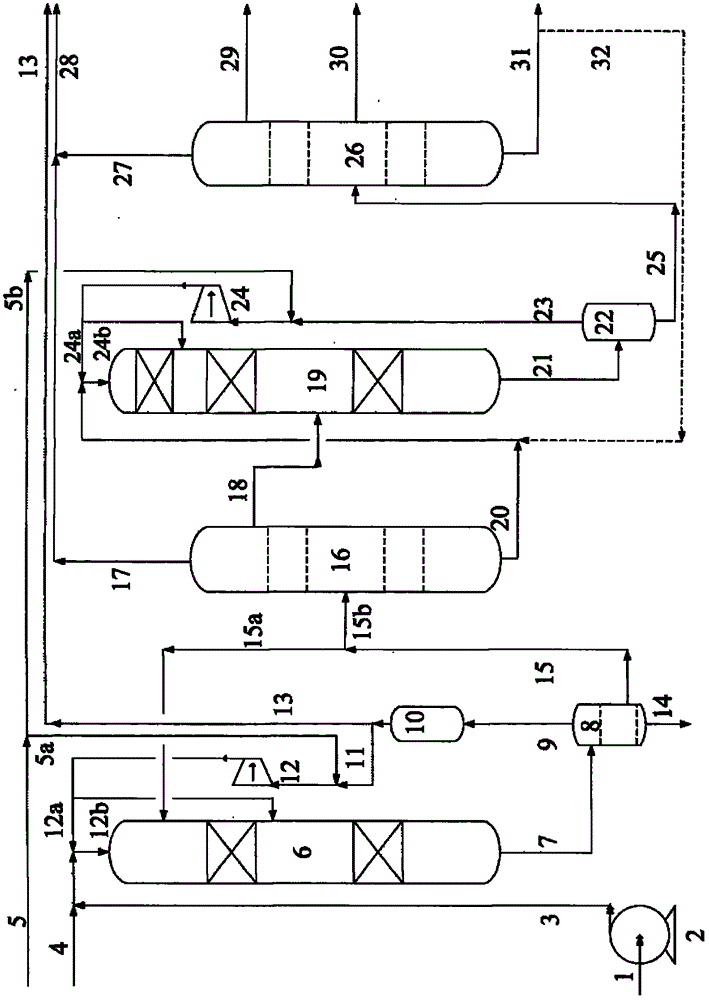

Method used

Image

Examples

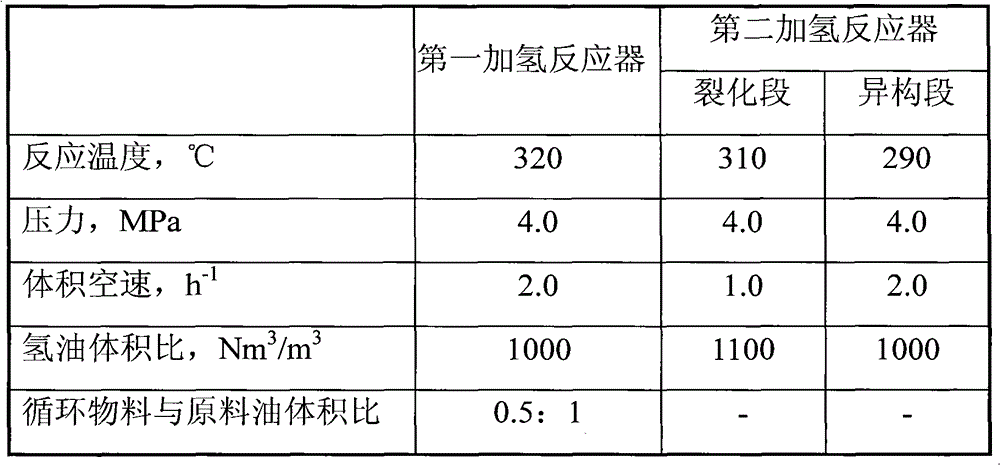

Embodiment 1

[0044] Coconut oil is used as the raw material, and the final diesel by-product is not re-refined. The reaction conditions are shown in Table 1.1, the product properties are shown in Table 1.2, and the raw material properties are shown in Table 3. Jet fuel yield was 41.5% by weight.

[0045] The reagents used in the preparation of catalysts were all chemically pure.

[0046]Wherein, the preparation method of the catalyst used in the first hydrogenation reactor is: take by weighing 2000 grams of aluminum hydroxide powder (70% by weight on a dry basis) and 631 grams of silica sol containing 25% by weight of silicon dioxide and mix them with an extruder to extrude Form a clover-shaped strip with a circumscribed circle diameter of 1.3 mm, dry the obtained clover-shaped strip at 120° C. for 4 hours and then bake it at 600° C. for 3 hours to obtain a carrier A. The silicon oxide content in the carrier A is 10.1% by weight. 200 g of the support A was impregnated with 176 ml of an aq...

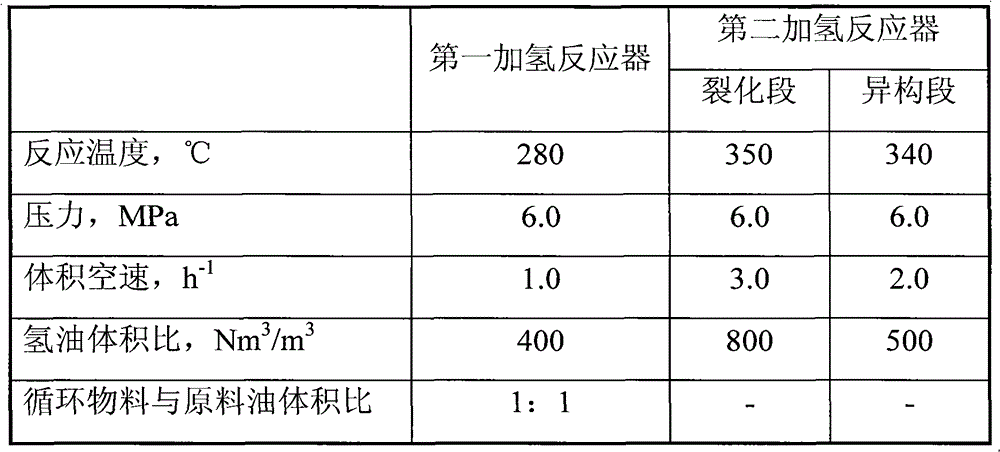

Embodiment 2

[0056] Adopt the same reactor and catalyst as Example 1, and the difference of Example 1 is that the raw material adopts the mixed oil of 70% by weight of palm oil and 30% by weight of lard, and the first hydrogenation reactor is provided with 3 hydrogenation Treat the catalyst bed, inject cold hydrogen between two adjacent catalyst beds to control the reaction temperature, 50% of the liquid hydrocarbon product obtained in the first hydrogenation reactor is mixed with the raw material and returned to the top of the reactor, and the reaction conditions are as shown in Table 2.1 The product properties are shown in Table 2.2. The properties of raw materials are shown in Table 3. Jet fuel yield was 39.8% by weight.

[0057] Table 2.1 Example 2 Operating Conditions

[0058]

[0059] Table 2.2 Product Properties of Example 2

[0060] Numbering

3 # jet fuel standard

Example 2

-47 (highest)

-62.2

Flash point, °C

3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com