Secondary coupled modified mineral powder filling material and preparation process thereof

A mineral powder and modification technology, which is applied in fibrous fillers, dyed organic silicon compound treatment, dyed low molecular organic compound treatment, etc., can solve problems such as difficulties and achieve improved reinforcement performance, good compatibility, and adhesion The effect of high branch efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of modified montmorillonite powder mineral filler:

[0022] Add 20kg of a mixture of acetone and ethyl acetate at a volume ratio of 1:1 into a 50L autoclave, then add 1.0kg of silane coupling agent, and stir to form a uniform solution. When the stirring speed is controlled below 25rpm, add 10kg of montmorillonite with a mineral content of 92% and a specific surface area of 105m 2 / g of powder, close the reactor, heat up to 60°C with electricity, control the stirring speed at 1500rpm, stir for 1h, and ultrasonically disperse for 20min during this period. After standing to cool, add 1.0kg of 1,4-pentadiene, continue to seal, keep warm at 90°C, and stir at 1500rpm for 2h, during which ultrasonic dispersion is 20min. After cooling and solid-liquid separation, the solid phase part is dried at 106° C., pulverized by a jet mill, sealed and stored to obtain secondary modified montmorillonite mineral powder.

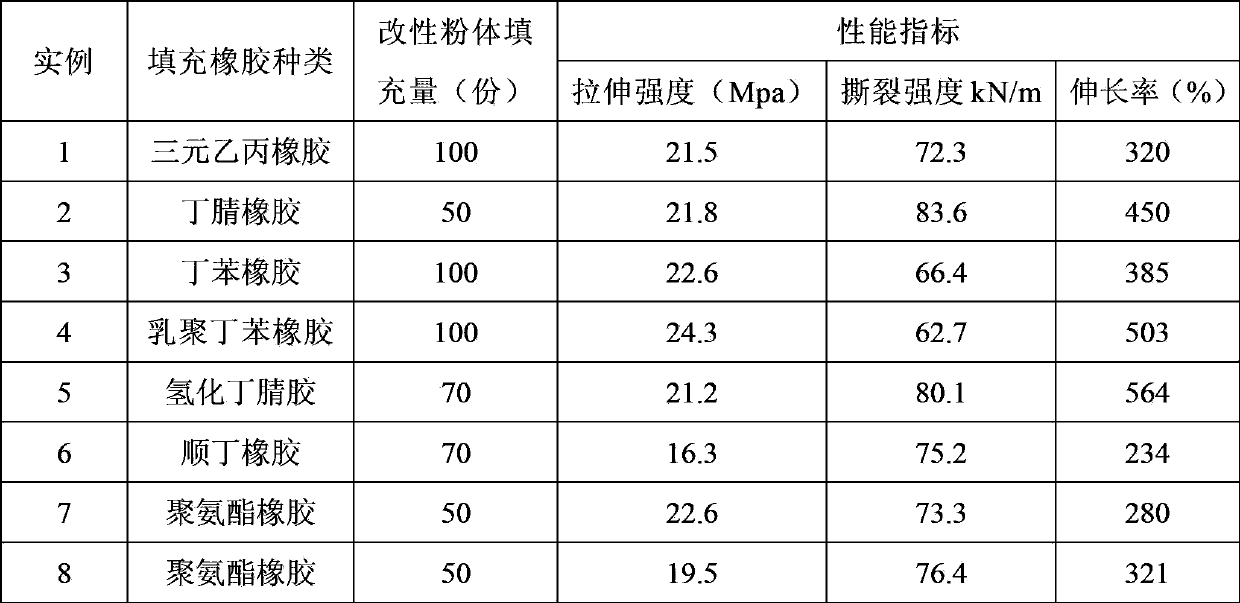

[0023] Use this powder to fill EPDM rubber, the formu...

Embodiment 2

[0025] Preparation of modified sepiolite mineral powder filler:

[0026] Add 20kg of n-butanol into a 50L autoclave, then add 0.1kg of silane coupling agent and 0.1kg of titanate coupling agent, and stir to form a uniform solution. When the stirring speed is controlled below 25rpm, add 10kg of sepiolite with a mineral content of 95% and a specific surface area of 126m 2 / g powder, close the reaction vessel, heat up to 90°C with electricity, control the stirring speed at 1500rpm, stir for 1h, and ultrasonically disperse for 20min during this period. After standing to cool, add 0.2kg of acrylonitrile, continue to seal, keep warm at 120°C, and stir at 1500rpm for 2h, during which ultrasonic dispersion is 20min. After cooling and solid-liquid separation, the solid phase part is dried at 120° C., pulverized by a jet mill, sealed and stored to obtain secondary coupling synergistically modified sepiolite mineral powder.

[0027] When using this powder to fill nitrile rubber, the ...

Embodiment 3

[0029] Preparation of modified attapulgite mineral powder filler:

[0030] Add 20kg of a mixture of isopropanol and toluene at a volume ratio of 1:1 into a 50L autoclave, then add 1.0kg of silane coupling agent and 1.0kg of titanate coupling agent, and stir to form a uniform solution. When the stirring speed is controlled below 25rpm, add 20kg of attapulgite with a mineral content of 98% and a specific surface area of 168m 2 / g powder, close the reaction vessel, heat up to 80°C with electricity, control the stirring speed at 1500rpm, stir for 1h, and ultrasonically disperse for 20min during this period. After standing to cool, add 1.0kg of polypropylene and 1.0kg of styrene, continue to seal, keep warm at 90°C, and stir at 1500rpm for 2h, during which ultrasonic dispersion is 20min. After cooling and solid-liquid separation, the solid phase part is dried at 110° C., pulverized by a jet mill, sealed and stored to obtain attapulgite mineral powder synergistically modified by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com