Composite flame retardant based on carbon microspheres and preparation method thereof

A technology of composite flame retardant and carbon microspheres, which is applied in the field of composite flame retardant and its preparation, can solve the problems of blank state of flame retardancy, achieve good thermal stability and mechanical properties, simple preparation process, wide application range wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

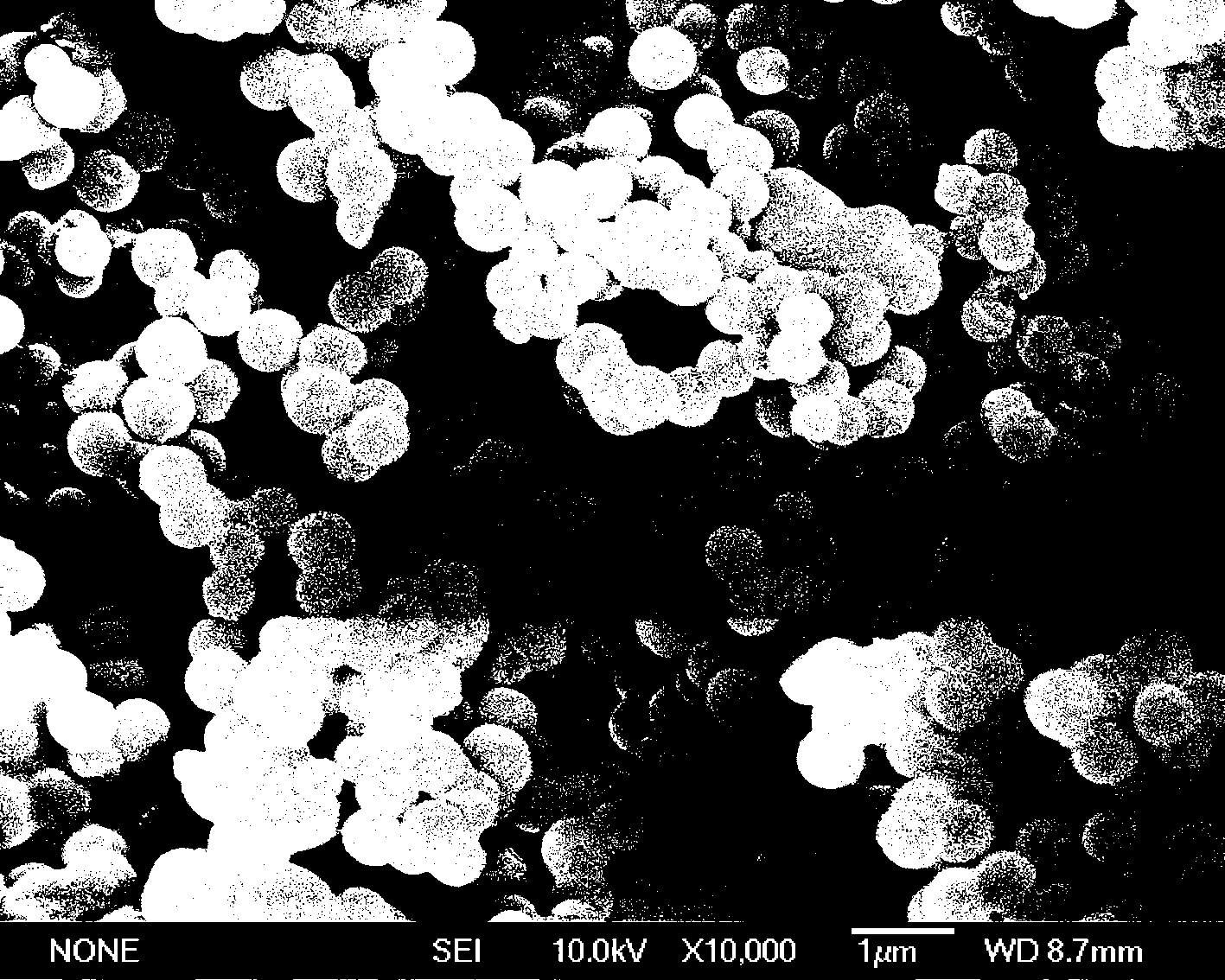

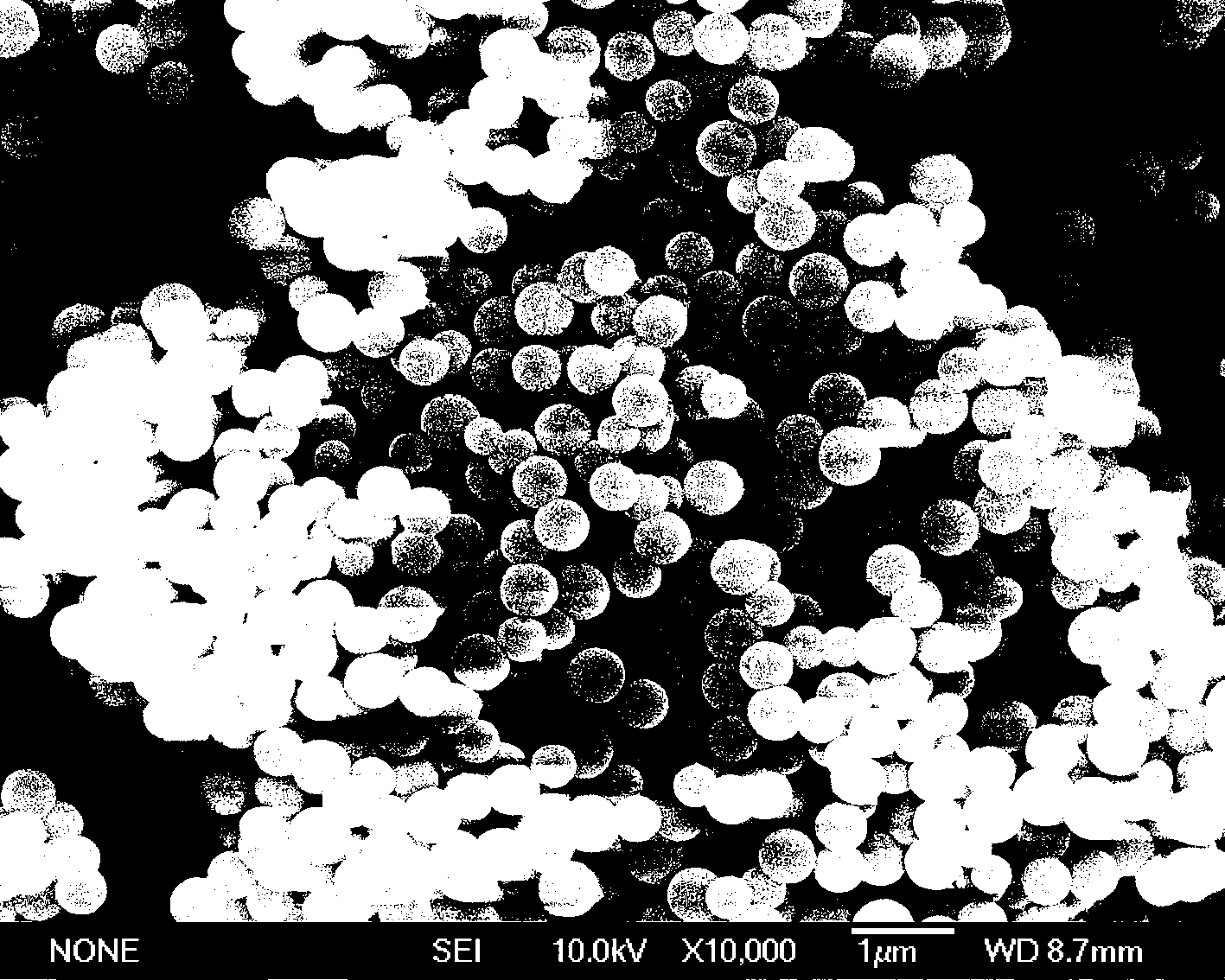

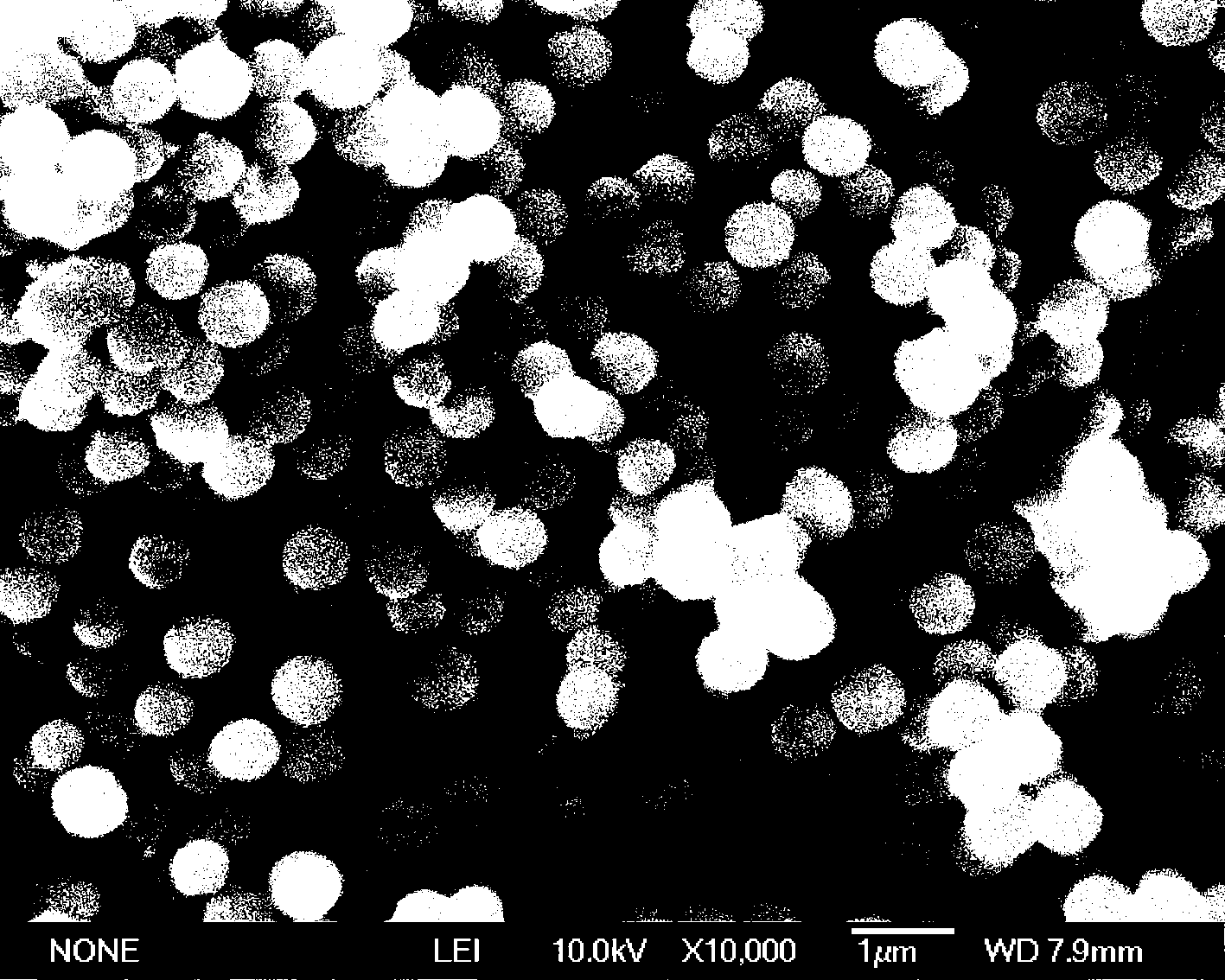

Image

Examples

Embodiment 1

[0028] Weigh 5g of carbon microspheres into a three-necked flask, add 300mL of nitric acid solution with a concentration of 5.943mol / L, and ultrasonically in an ultrasonic disperser with a frequency of 40kHz and a power of 60W for 30min, then raise the temperature to 60°C under stirring, and react at a constant temperature for 30min. Cool to room temperature. The reaction product was suction-filtered and washed with deionized water until the pH value was 7, and the filter cake was dried at 120° C. for 300 min to obtain acidified carbon microspheres.

[0029] Take 2.5g of acidified carbon microspheres into a three-necked flask, add 250mL of N,N-dimethylformamide and 1g of N,N-dicyclohexylcarbodiimide in turn, and ultrasonically After 30 minutes, stir and heat up to 25°C, slowly add 5mL of aniline solution into the three-necked flask, and react for 24 hours. The product was washed with N,N-dimethylformamide and filtered until the washing solution was clear, then washed with dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com