Method for preparing phosphate fertilizer soil conditioner by utilizing phosphate tailings and acid wastewater

A soil conditioner, acid waste water technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of high cost, unutilized phosphorus resources, no way to further recover, etc., to reduce land area, reduce treatment costs and Emissions, tailings reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare raw materials: Phosphate rock scrubbing ore dressing tailings containing P 2 o 5 15%~18%, pulp concentration 30%~35%.

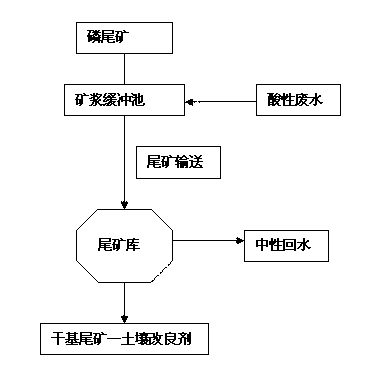

[0034] Add acidic wastewater containing sulfuric acid with a mass concentration of 8% to 10% to the raw materials, and the acidic wastewater also contains lead, cadmium, and arsenic that meet the discharge standards, such as figure 1 As shown, mix with phosphorus tailings in the tailings buffer pool for 10 to 15 minutes, transport the mixed slurry from the tailings buffer pool to the tailings pond, and control the amount of acid waste water added to the tailings water discharged from the tailings pond If the pH value is greater than 6.8, after 6 to 12 months of stockpiling, the tailings with a water content of less than 10% on a dry basis in the tailings pond will become 12% to 14% active P 2 o 5 It is a soil conditioner with the effect of calcium magnesium phosphate fertilizer.

Embodiment 2

[0036] Prepare raw materials: phosphate rock flotation tailings containing P 2 o 5 12%~15%, pulp concentration 25%~30%.

[0037] Add acidic wastewater containing sulfuric acid with a mass concentration of 5% to 8% to the raw materials, and the acidic wastewater also contains lead, cadmium, and arsenic that meet the discharge standards, such as figure 1 As shown, mix with phosphorus tailings in the tailings buffer pool for 10 to 15 minutes, transport the mixed slurry from the tailings buffer pool to the tailings pond, and control the amount of acid waste water added to the tailings water discharged from the tailings pond If the pH value is greater than 6.8, after 6 to 12 months of stockpiling, the tailings with a water content of less than 10% on a dry basis in the tailings pond will become 9% to 12% active P 2 o 5 It is a soil conditioner with the effect of calcium magnesium phosphate fertilizer.

Embodiment 3

[0039] Prepare raw materials: phosphate rock flotation tailings containing P 2 o 5 10%~12%, pulp concentration 20%~25%.

[0040] Add acidic wastewater containing sulfuric acid with a mass concentration of 5% to 8% to the raw materials, and the acidic wastewater also contains lead, cadmium, and arsenic that meet the discharge standards, such as figure 1 As shown, mix with phosphorus tailings in the tailings buffer pool for 10 to 15 minutes, transport the mixed slurry from the tailings buffer pool to the tailings pond, and control the amount of acid waste water added to the tailings water discharged from the tailings pond If the pH value is greater than 6.8, after 6 to 12 months of stockpiling, the tailings with a water content of less than 10% on a dry basis in the tailings pond will become 7% to 9% active P 2 o 5 It is a soil conditioner with the effect of calcium magnesium phosphate fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com