Material for cast steel evaporative pattern and preparation method of material

A technology of lost foam casting and steel casting, which is applied in the field of materials, can solve the problems of insufficient brushability and high-temperature strength, stimulation, etc., achieve the best peeling effect, improve quality, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

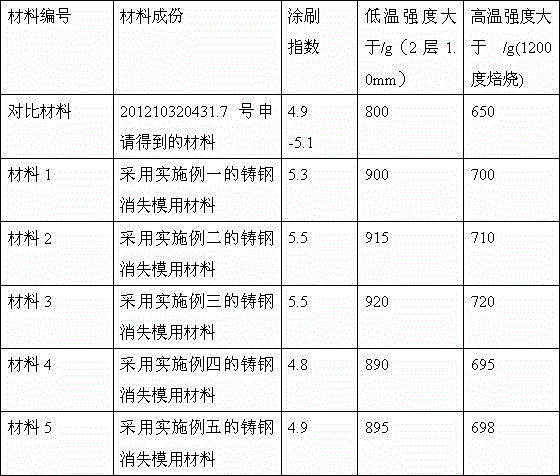

Examples

Embodiment 1

[0032] The preparation method of the lost foam casting material for cast steel of the present invention, the method comprises the following steps:

[0033] 1) Preparation of nanoscale (Na, Ca) (Mn, Fe, Mg, Al) [(Si, Al)2O6] composite powder:

[0034] Dissolve 20g of aluminum hydroxide (Al(OH)3 in 200mL of 10mol / L potassium hydroxide aqueous solution; then put it in a container and heat it to 120°C, keep it warm for 26 hours, filter out the precipitate with filter paper, and wash it with deionized water Wash 5 times; then heat the washed precipitate to 400°C for 1 hour in a high-temperature furnace to obtain product A for use;

[0035] Mix 20mL of silica sol, 80mL of 5% nitric acid aqueous solution and 320mL of ethanol and stir until a uniform mixed solution is formed; In the formed mixture; ultrasonically stir at 50-55°C for 0.5h at an ultrasonic frequency of 50kHz and a power of 400W, add dropwise 40mL of ammonia water with a concentration of 10% by mass, and colloid B appea...

Embodiment 2

[0041] The mass ratio of product A, colloid B and (Na, Ca)(Mn, Fe, Mg, Al) [(Si, Al)2O6] powder mixed in step 1) is 1:1:1.1.

[0042] Step 3) Preparation of materials for cast steel lost foam: the weight percentage of each component is: nano-scale (Na, Ca) (Mn, Fe, Mg, Al) [(Si, Al)2O6] composite powder 23% , 8% slag powder, 0.8% sodium dodecylbenzenesulfonate, 8% lithium bentonite, 31% 3-methyl-2-buten-1-ol acetate composite solution, and the rest brown corundum powder.

[0043] All the other preparation processes are the same as in Example 1.

Embodiment 3

[0045] The mass ratio of product A, colloid B and (Na, Ca) (Mn, Fe, Mg, Al) [(Si, Al)2O6] powder mixed in step 1) is 1:1:0.9.

[0046] Step 3) Preparation of materials for cast steel lost foam: the weight percentage of each component is: nano-scale (Na, Ca) (Mn, Fe, Mg, Al) [(Si, Al)2O6] composite powder 22%, Slag powder 5%, sodium dodecylbenzene sulfonate 0.6%, lithium bentonite 6-8%, 3-methyl-2-buten-1-ol acetate composite solution 30%, brown corundum powder and the rest .

[0047] All the other preparation processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com