Preparation method of efficient and stable Fe (III)/AgBr composite visible photocatalyst

A photocatalyst and visible light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of low equipment requirements, high visible light photocatalytic performance, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation process of Fe(III) / AgBr composite visible light photocatalyst is as follows: 1) Preparation of AgBr particles: 5.3 mL 0.01 mol / L silver nitrate solution was added to 5.3 mL 0.01 mol / L sodium bromide solution, at 60 o C for 2 h, and then washed the yellow precipitate with deionized water for 3 times, after 60 o C. Dry in vacuum for 2 h to obtain AgBr particles with a size of 1-3 mm; 2) Fe(III) modification on the surface of AgBr particles: Take 0.1 g of AgBr particles and add them to 15 mL of 0.005 mol / L ferric nitrate solution, shake After uniformity, at 60 o C water bath was incubated for 2 h, the precipitate in the obtained reaction solution was filtered, washed with deionized water three times, and finally vacuum-dried at 60 °C for 2 h to obtain a highly efficient and stable Fe(III) / AgBr composite visible light photocatalyst.

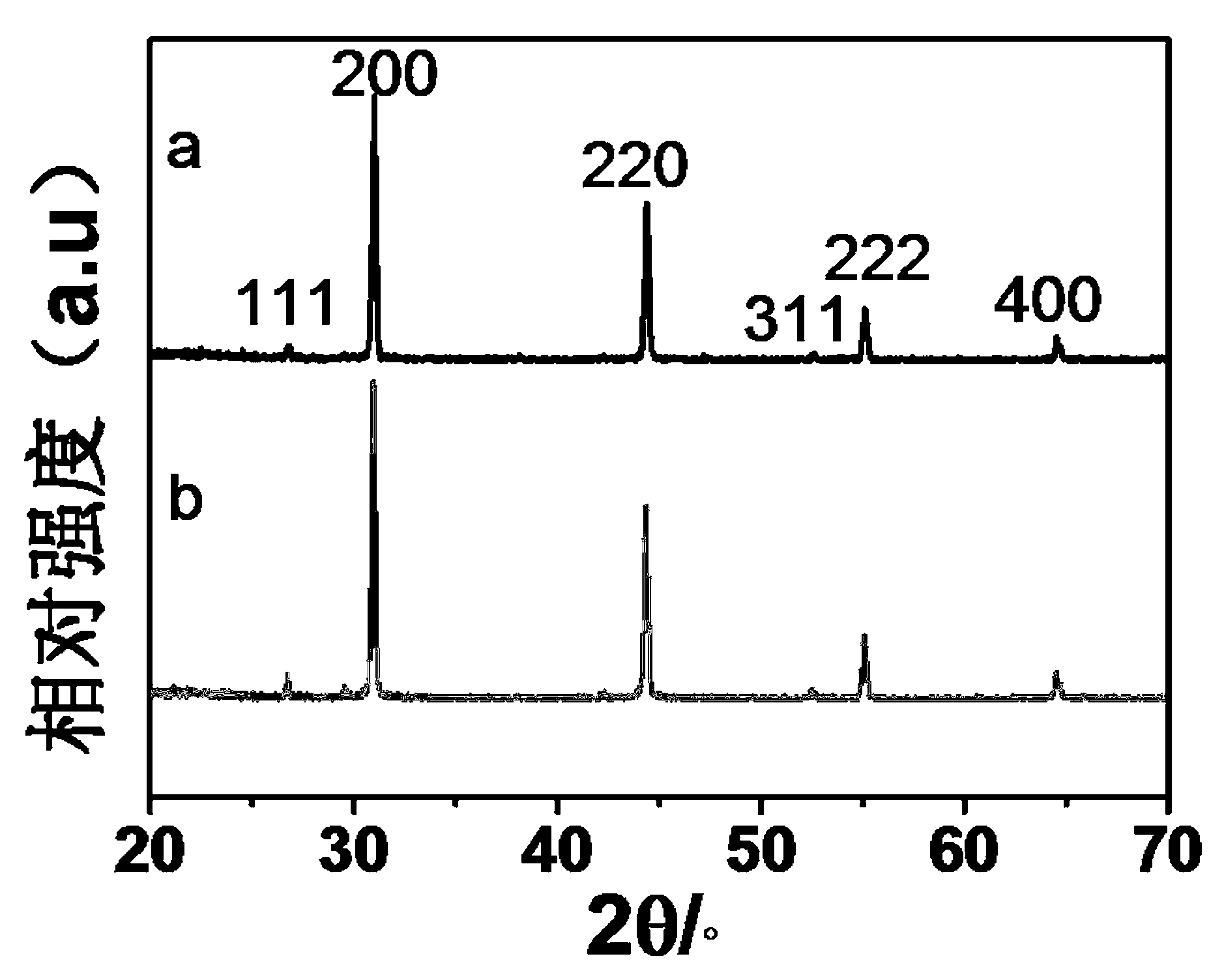

[0030] The microstructure characterization method of Fe(III) / AgBr composite visible light photocatalyst: the morphology and ...

Embodiment 2

[0039] In order to examine the effect of ferric nitrate concentration on the photocatalytic performance of Fe(III) / AgBr composite visible light photocatalyst, in addition to the different concentration of ferric nitrate, other reaction conditions such as water bath temperature (60°C), water bath time (2 h), drying temperature ( 60°C) and drying time (2 h) were the same as in Example 1. The results showed that when the concentration of ferric nitrate was 0.0001, 0.001, 0.005, 0.01 and 0.05, the degradation rate constants of Fe(III) / AgBr composite visible light photocatalyst for methyl orange were 0.065, 0.091, 0.113, 0.075 and 0.056, respectively. min -1 . The main reason is that when the concentration of Fe(III) is 0.0001 mol / L, because the concentration of Fe(III) is too low, only a small amount of Fe(III) is compounded on the surface of AgBr particles, making the photocatalytic performance of Fe(III) / AgBr lower; when the concentration of Fe(III) is 0.001-0.01 mol / L, becaus...

Embodiment 3

[0041] In order to test the effect of water bath temperature on the photocatalytic performance of Fe(III) / AgBr composite visible light photocatalyst, in addition to different water bath temperatures, other reaction conditions such as ferric nitrate concentration (0.005 mol / L), water bath time (2 h), drying temperature (60°C), drying time (2 h), etc. are all the same as in Example 1. The results showed that when the water bath temperature was 30, 60, 80 and 100 ℃, the degradation rate constants of the obtained Fe(III) / AgBr composite visible light photocatalyst to methyl orange were 0.105, 0.113, 0.094 and 0.062 min, respectively -1 . The main reason is that when the temperature of the water bath is 30-80°C, Fe(III) can be well combined with AgBr particles to form a Fe(III) / AgBr composite structure, and the higher temperature (100°C) is easy to make the ferric nitrate solution Hydrolysis to form Fe(OH) 3 Colloids are not conducive to the formation of Fe(III) / AgBr composite str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com