Catalyst for synthesizing oxalic ester through oxidative coupling of CO gas phase as well as preparation and application method thereof

A catalyst and oxidation couple technology, applied in the field of oxalate ester preparation, can solve the problems of poor catalytic performance, high price, limited reserves, etc., achieve good catalytic activity and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Will K 2 PdCl 4 Dissolve in deionized water to prepare a Pd ion concentration of 0.01M solution, then add 1.06g of nano-magnesium oxide to the above 5ml solution and stir for 2 hours, and ultrasonically disperse in a water bath at 50℃ with 200W energy until the solvent evaporates to dryness to obtain a solid Things. Dry the solid at 100°C for 8 hours, then roast it in an air atmosphere at 400°C for 4 hours, and then reduce it with reducing gas (hydrogen-nitrogen mixed gas) at a temperature of 300°C for 3 hours. The reducing gas space velocity is 3000 h -1 , And then lower the temperature to room temperature in a reducing atmosphere to obtain the desired catalyst. The loading of Pd is 0.5% of the carrier mass.

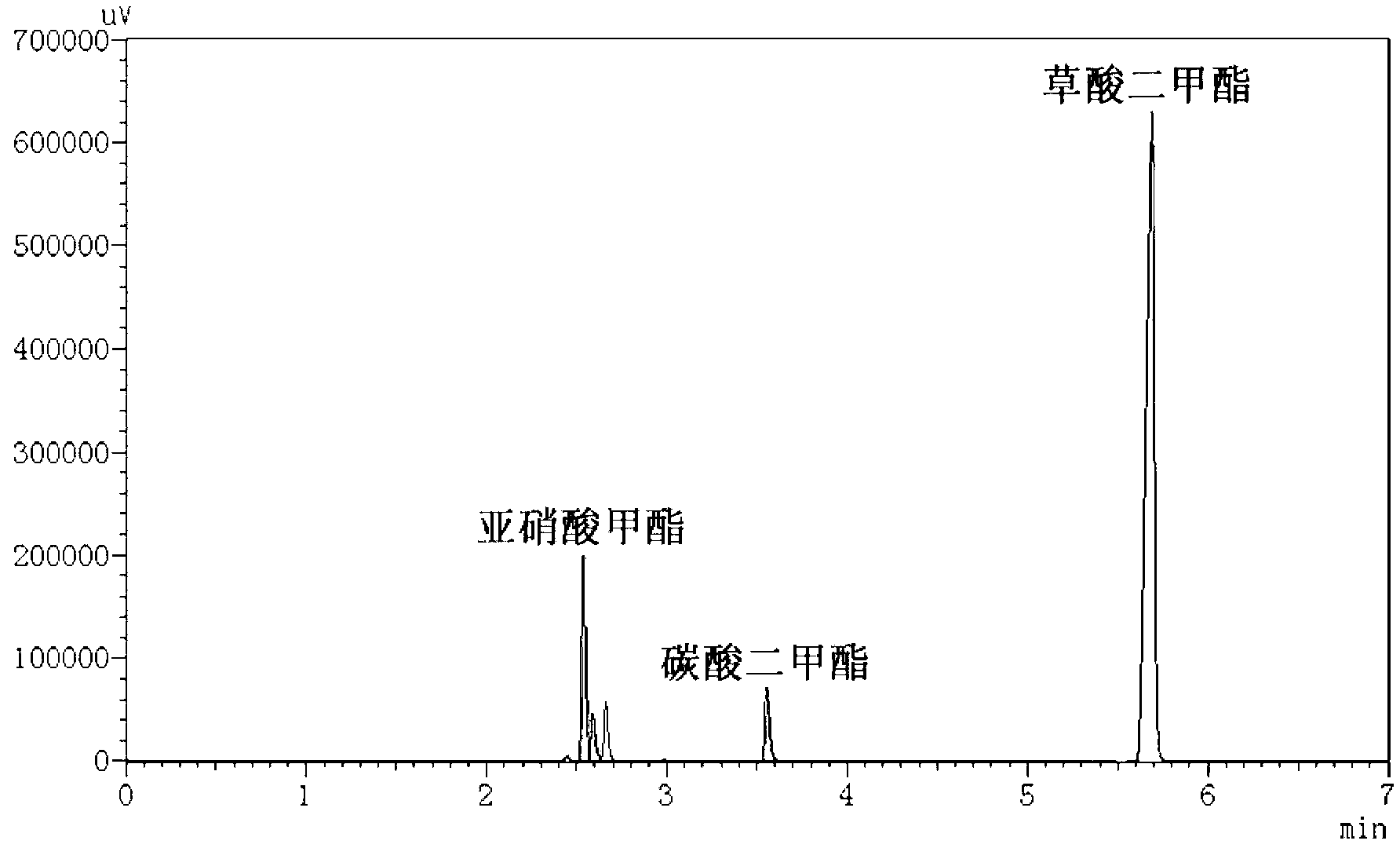

[0034] Catalyst evaluation: The catalyst in the example of the present invention is applied to the CO gas phase oxidative coupling synthesis of oxalate. The amount of catalyst is 1 mL, the flow ratio of feed gas CO and methyl nitrite is 1.4, and the gas space veloci...

Embodiment 2

[0040] Pd(OAc) 2 Dissolve in acetone to prepare a solution with a Pd ion concentration of 0.005M, then add 1.06g of nano-magnesium oxide to the above 10ml solution and stir for 0.5 hours, and ultrasonically disperse in a water bath at 25°C with 200W energy until the solvent evaporates to dryness to obtain a solid. . The solid was dried at 100°C for 8 hours, and then calcined in an air atmosphere at 400°C for 4 hours, and then reduced with pure hydrogen at a temperature of 300°C for 3 hours. The reducing gas space velocity was 3000 h -1 , And then lower the temperature to room temperature in a reducing atmosphere to obtain the desired catalyst. The loading of Pd is 0.5% of the carrier mass.

Embodiment 3

[0042] Pd(acac) 2 Dissolve in acetone to prepare a solution with a Pd ion concentration of 0.005M, then add 1.06g of nano-magnesium oxide to the above 10ml solution and stir for 0.5 hours, and ultrasonically disperse in a water bath at 25°C with 200W energy until the solvent evaporates to dryness to obtain a solid. . The solid was dried at 100°C for 8 hours, and then calcined in an air atmosphere at 400°C for 4 hours, and then reduced with pure hydrogen at a temperature of 300°C for 3 hours. The reducing gas space velocity was 3000 h -1 , And then lower the temperature to room temperature in a reducing atmosphere to obtain the desired catalyst. The loading of Pd is 0.5% of the carrier mass.

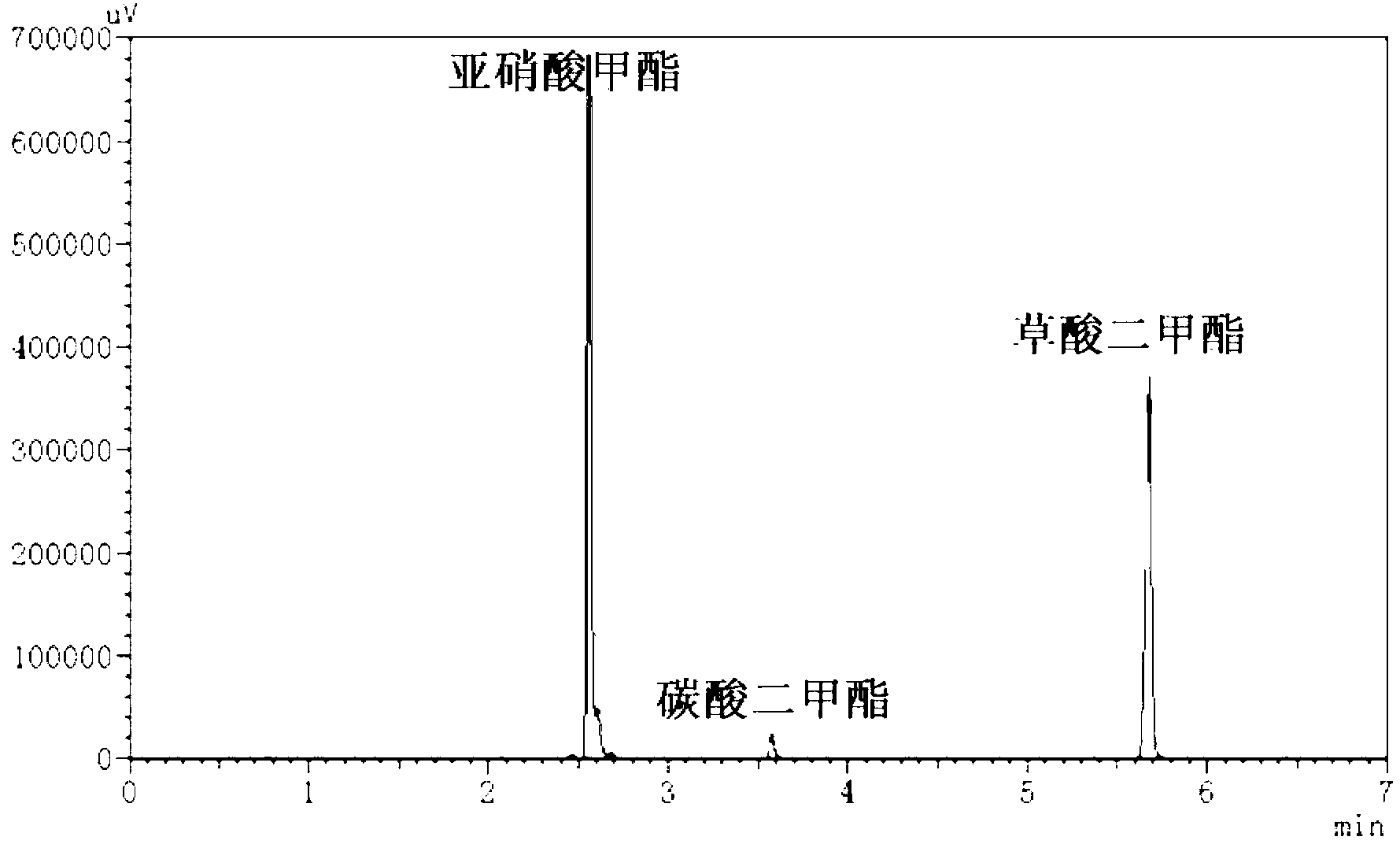

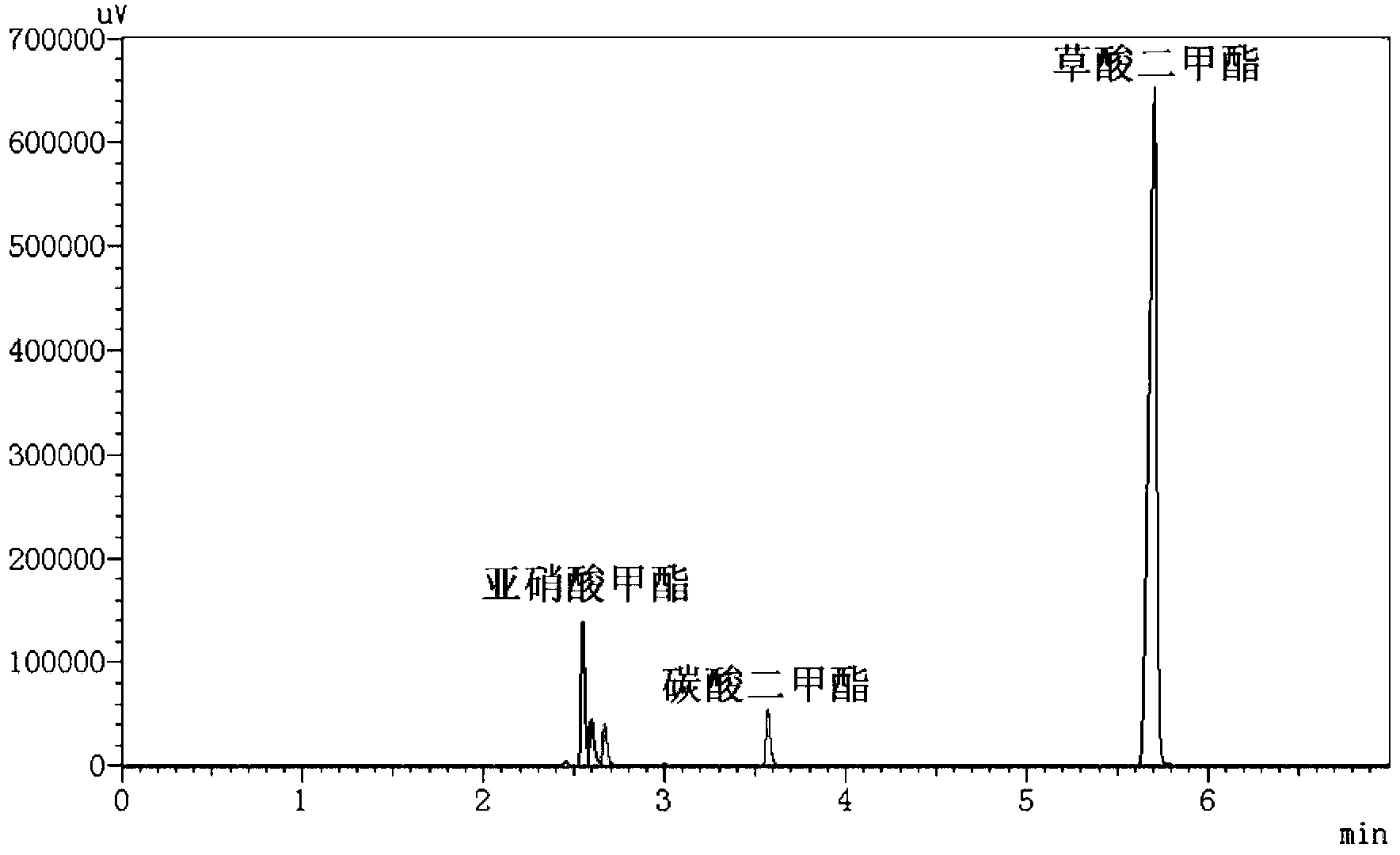

[0043] The catalysts of Comparative Example 1, Example 2 and Example 3 were evaluated in the same manner as in Example 1. The reaction temperature was 140°C. The chromatographic analysis chart is shown in figure 2 , image 3 with Figure 4 , The reaction results are shown in Table 2.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com