Grain-saving and environmentally-friendly microbial fermented feed and manufacturing method thereof

A microbial fermentation and feed technology, which is applied in the field of livestock and poultry feed, can solve the problems of difficult to control fermentation degree, low nutritional value, and easy to contaminate bacteria and mildew, so as to reduce breeding costs, stabilize product quality, and increase feed intake. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A grain-saving and environmentally friendly microbial fermented feed is prepared by mixing and fermenting the following components according to the weight ratio: 351 parts of peanut shell powder, 32 parts of secondary powder, 20 parts of bran, 54 parts of worm sand, 500 parts of brewer's grains, 20 parts of premix, 23 parts of bacterial liquid;

[0036] The premix is composed of the following components by weight fraction: 452 parts of stone powder, 330 parts of zeolite powder, 24 parts of compound multidimensional, 50 parts of calcium hydrogen phosphate, 50 parts of sprayed corn husks, 90 parts of table salt, and 2 parts of flavoring agent parts, 2 parts of sweetener;

[0037] The compound multidimensional ratio is as follows:

[0038] Vitamin A 20000IU / kg Vitamin D 3 10000IU / kg

[0039] Vitamin E 110mg / kg Vitamin K 3 10mg / kg

[0040] Vitamin B 1 8mg / kg Vitamin B 2 12mg / kg

[0041] Vitamin B 6 7mg / kg Vitamin B 12 0.2mg / kg

[0042] Biotin 25mg...

Embodiment 2

[0049] The preparation method of a kind of grain-saving and environment-friendly microbial fermented feed described in embodiment 1, concrete process is as follows:

[0050] 1) Preparation of bacterial solution

[0051] A. Preparation of Pichia strain: inoculate the preserved strains into 250mL eggplant bottles filled with 70-80mL solid slant potato medium, and cultivate them in a constant temperature incubator at 30°C for 3 days; Rinse down the bacteria with sterile water, and repeatedly blow and suck to mix the bacteria and sterile water evenly to obtain a bacterial suspension. Put 3% of the inoculum into a 500mL triangular flask containing 300mL of YPD medium, and shake at a constant temperature of 30°C. Bed culture for 24 hours, rotating speed 220rpm; transfer 3% inoculum amount into a 500mL Erlenmeyer flask containing 300mL fermentation medium, culture in a constant temperature shaker at 30°C for 24 hours, rotating speed 220rpm;

[0052] The formula of the potato medium ...

Embodiment 3

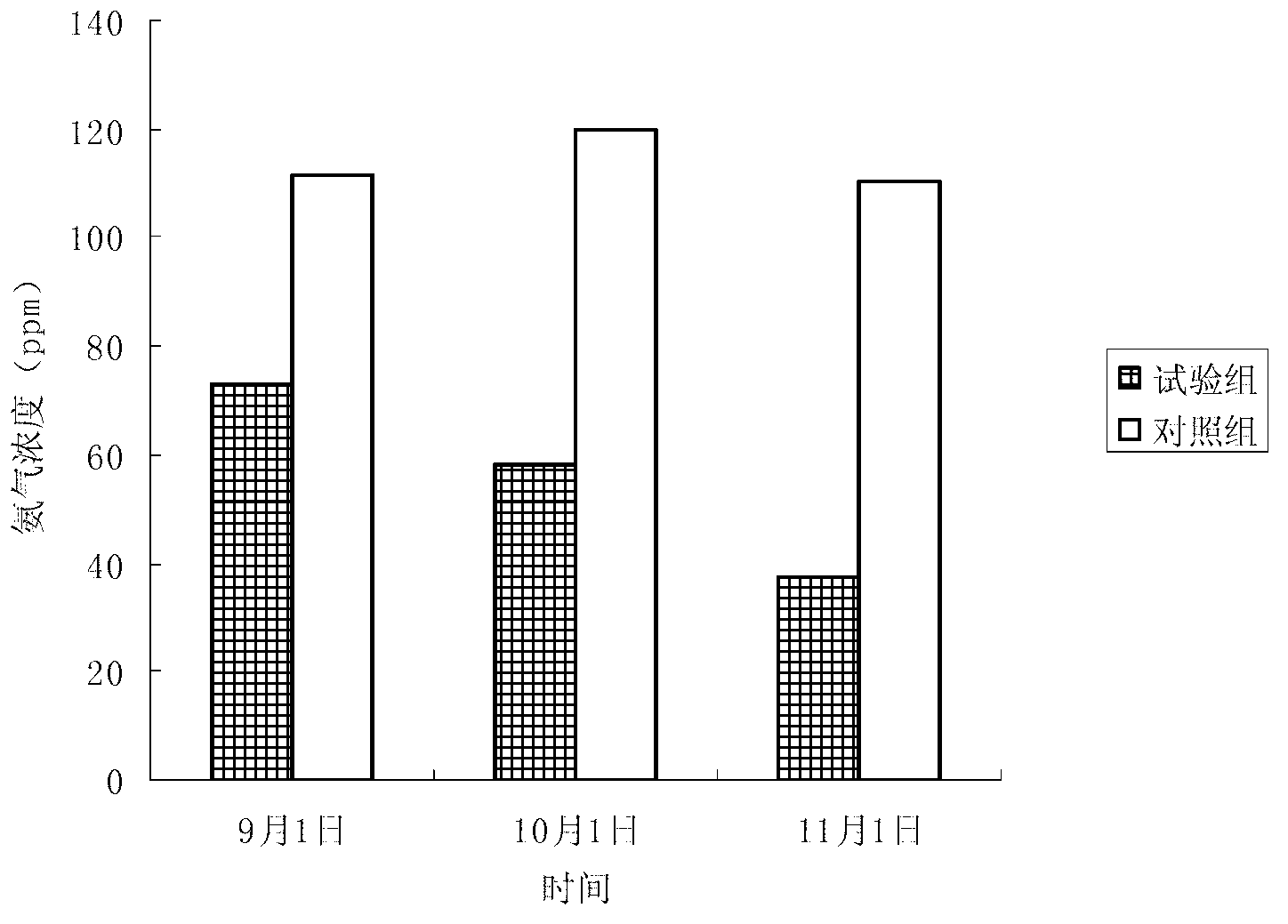

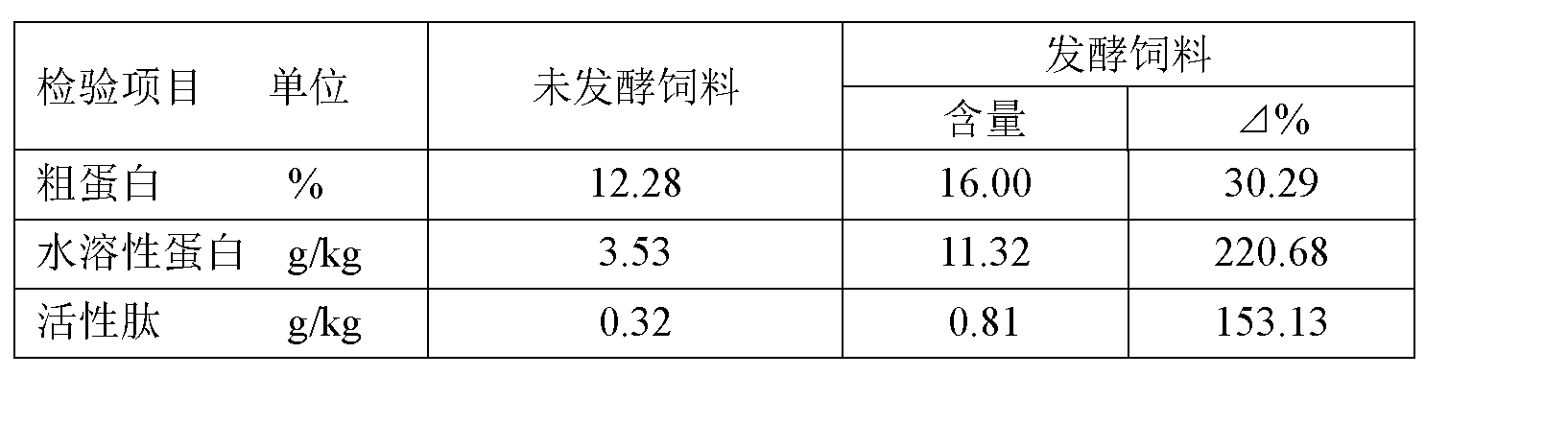

[0066] The grain-saving environmental protection microbial fermented feed nutrient composition determination in embodiment 1:

[0067] 1. The crude protein content in the fermented feed was 16%; the content of three active substances: ① The free amino acid content was 47.09 g / kg, and the fermentation increase rate was 111.26%. ②The active peptide content was 0.81 g / kg, and the fermentation increase rate was 153.13%. ③The water-soluble protein content was 11.32 g / kg, and the fermentation increase rate was 220.68%.

[0068] 2. Three kinds of hydrolase activities in the fermented feed: ① The protease activity was 546.35 U, and the fermentation increase rate was 264.09%. ②The cellulase activity was 5942.67U, and the fermentation increase rate was 94.06%. ③The activity of phytase was 106.45U, and the fermentation rate was 300.04%.

[0069] test methods

[0070] Determination of protein content

[0071] Crush and sieve the dried sample, weigh 0.5000g into a small Erlenmeyer flas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com