Overhead transmission line integrated operation robot

A technology for overhead transmission lines and working robots, applied in the field of electric power, can solve the problems of difficult robot processing and installation, easy shaking of robots, poor stability, etc., and achieve the effects of stable movement, easy adjustment, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

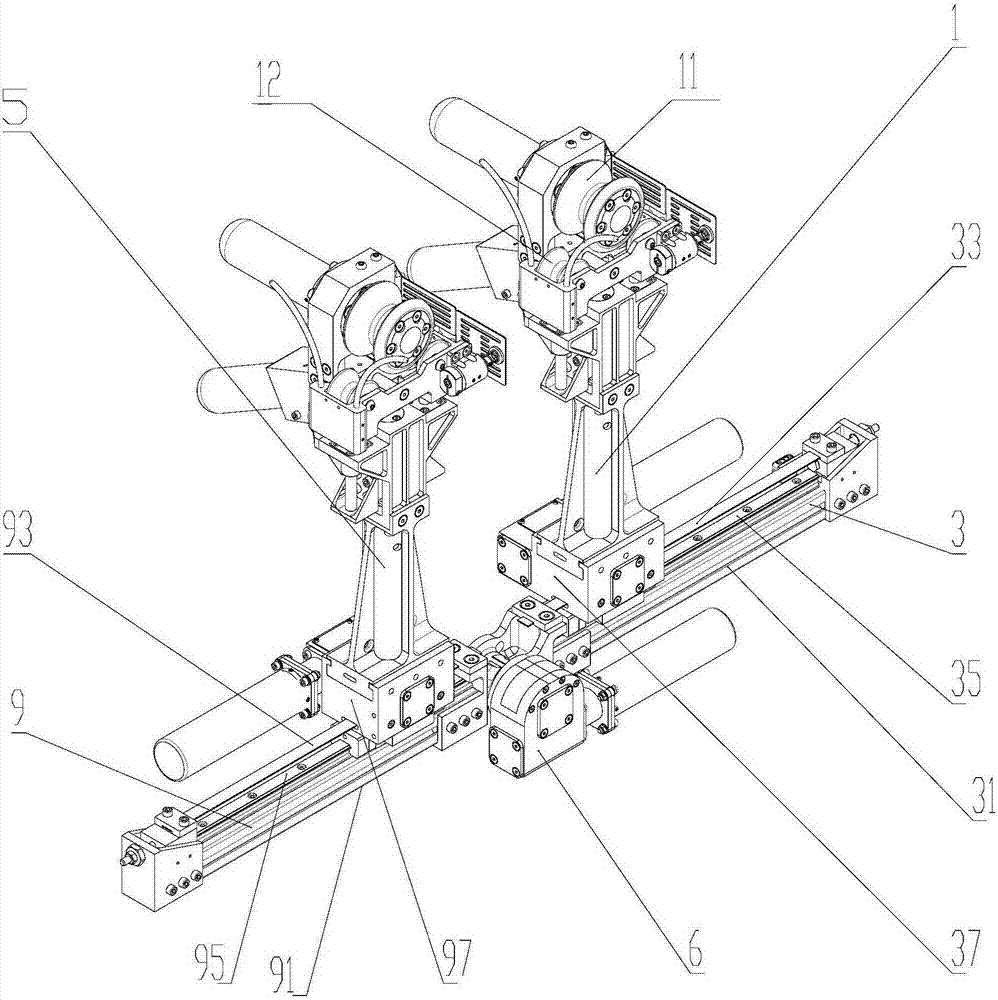

[0034] Such as figure 1 As shown, the overhead power transmission line comprehensive operation robot according to the embodiment of the present invention includes:

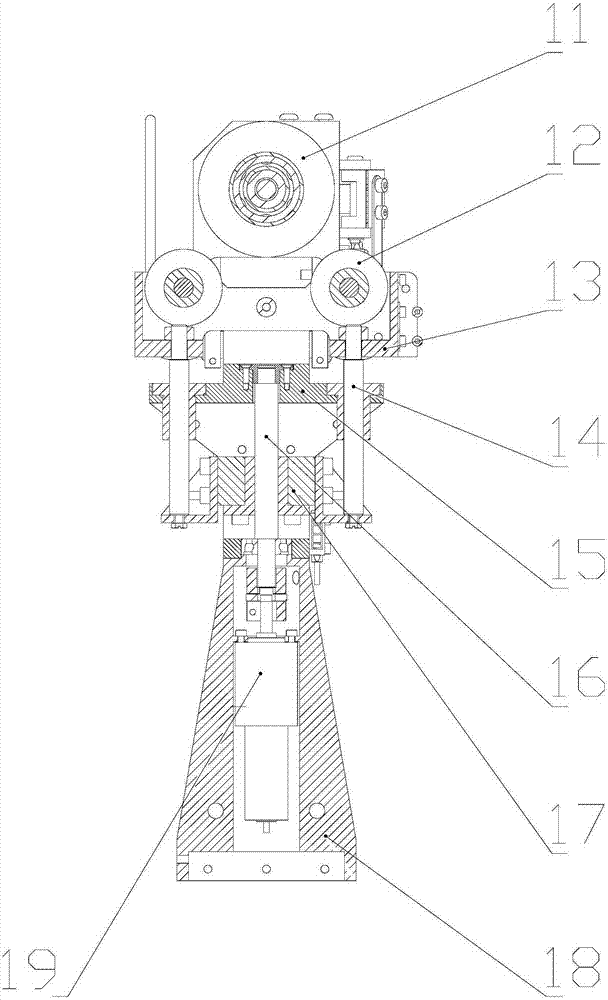

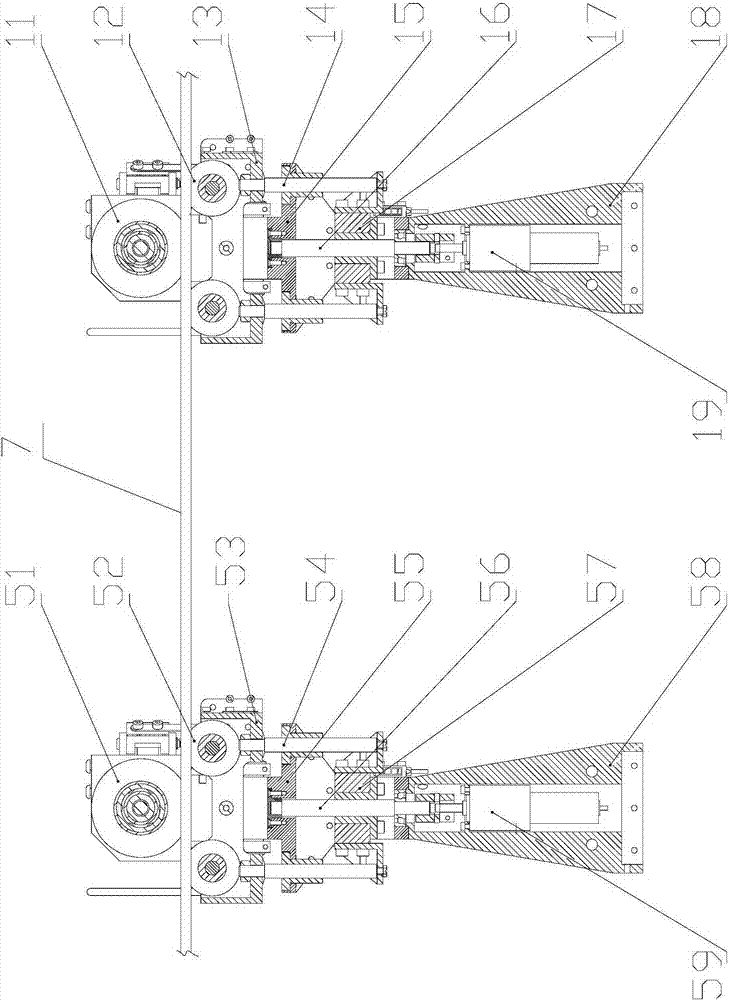

[0035] The forearm 3 and the rear arm 9 that are hingedly connected by the middle rotary joint 6, such as Figure 6a , 6d and Figure 6e , the forearm 3 and the rear arm 9 can form various angles by mutual rotation. Such as Figure 5 The middle swivel joint 6 has a hinge shaft 60 and a motor 62 that drives the hinge shaft 60 to rotate. The motor 62 drives the hinge shaft 60 to rotate. The middle swivel joint 6 drives the forearm 3 and the rear arm 9 to rotate mutually to realize obstacle surmounting. The specific structure of the intermediate rotary joint 6 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com