Lithium sulfur battery

A technology for lithium-sulfur batteries and battery casings, applied in the field of lithium-sulfur batteries, can solve problems such as insufficient and outdated electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

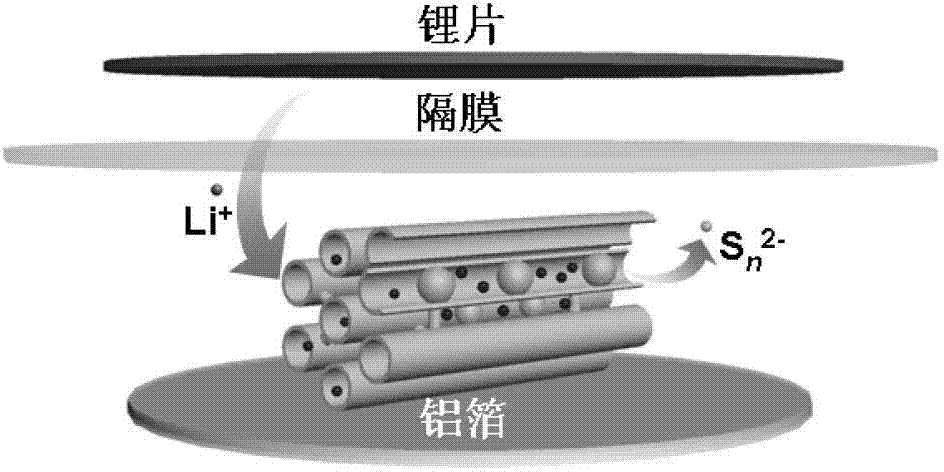

[0027] Preparation of carbon carrier: For the preparation method of ordered tubular mesoporous carbon in the present invention, see A.-H.Lu et al., Adv.Mater.2003,15,1602 and A.-H.Lu et al., J. Am. Chem. Soc. 2010, 132, 14152. Using mesoporous silicon SBA-15 as a template, mix SBA-15, trimethylbenzene, furfuryl alcohol and oxalic acid evenly, after heat treatment at 50-90°C, carbonize at 500-800°C for 3-8h, and then remove silicon with NaOH, Ordered tubular mesoporous carbon was obtained, showing the characteristics of thin-walled double channels.

[0028] The production of sulfur-based composite materials: mechanically mix elemental sulfur and carbon materials at a mass ratio of 1:1.7, then heat to 155°C under the protection of an inert gas and keep it warm for 6h, then raise the temperature to 300°C and keep it warm for 1h, and get S / C composites with S content of 50wt%.

[0029] Electrode sheet production: put a 35-micron-thick copper foil (Huizhou United Copper Foil) cur...

Embodiment 2

[0032] The preparation of the electrode material is the same as in Example 1. Different from embodiment 1 is the current collector:

[0033] Use 15 micron carbon-coated aluminum foil (Pinen Technology) as the current collector, rinse with acetone before use. Then the prepared slurry is coated on it, and the sheet is dried and punched to obtain an electrode sheet. The battery assembly and testing were the same as in Example 1. Charge and discharge at 0.2C, the specific capacity of the first discharge is 1021mAhg -1 , the specific capacity after 100 cycles is only 527mAhg -1 , the reversible capacity fades seriously, and the Coulombic efficiency is <85%.

Embodiment 3

[0035] The preparation of the electrode material is the same as in Example 1. Different from embodiment 1 is the current collector:

[0036] Use 1.59 mm thick nickel foam (Liyuan new material) as the current collector, and put it in acetone for ultrasonic cleaning for 10 minutes before use. Then the prepared slurry is coated on it, and the sheet is dried and punched to obtain an electrode sheet. The battery assembly and testing were the same as in Example 1. Charge and discharge at 0.2C, the first discharge specific capacity is 1097mA h g -1 , the specific capacity after 40 cycles is 585mA h g -1 , the specific capacity can be maintained at 577mA h g after 100 cycles -1 , the attenuation is serious in the early stage, and the cycle performance is basically stable after 40 charges and discharges.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com