Method of crack resistance and seepage prevention for concrete roof eave edging in archaized architectures

A technology that imitates ancient buildings and concrete. It is applied in the direction of building roofs, roof coverings, and roof drainage. It can solve problems that affect the effect of perception, and achieve the effect of improving the paste effect, sticking firmly, and ensuring firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

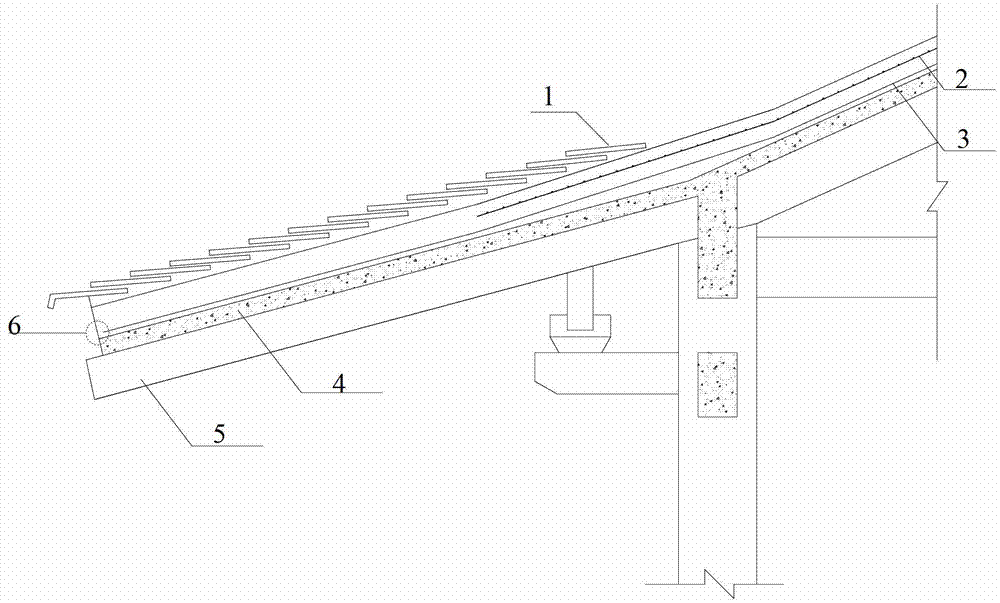

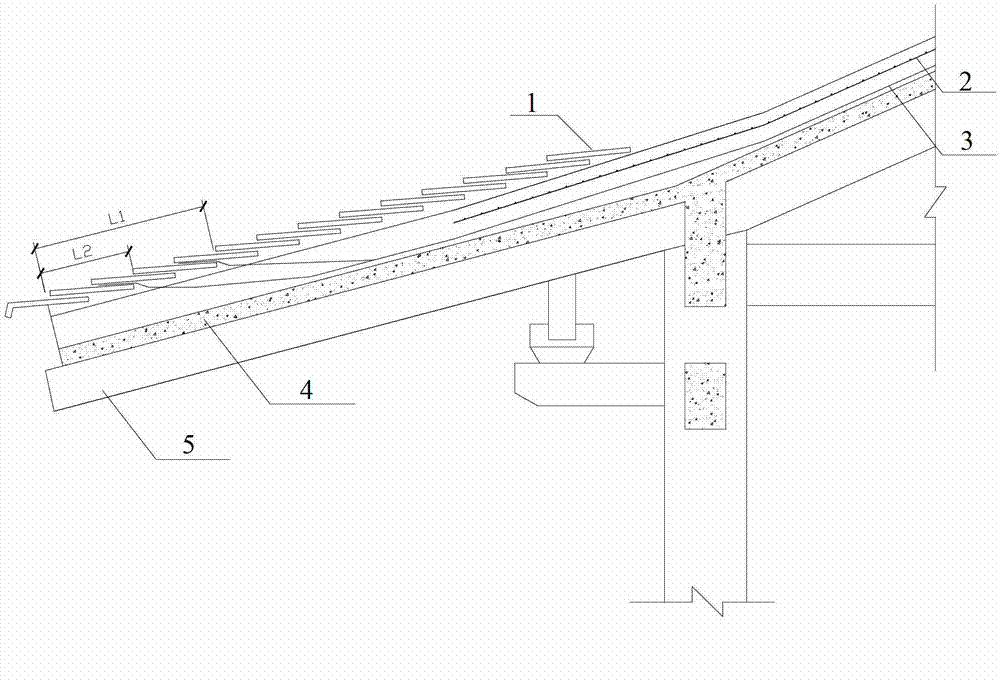

[0024] The anti-crack and anti-seepage method of the concrete roof of the antique building concrete roof proposed by the present invention is aimed at the antique building structure such as figure 2 Shown: include reinforced concrete rafters 5, reinforced concrete roof 4, lay waterproof layer 3 on the reinforced concrete roof 4, and also be provided with reinforced mesh sheet 2 on the upper layer of waterproof layer 3, then fix roof tile 1. In the present invention, the lower end of the waterproof layer 3 of the antique building roof is turned up and crimped in the lap joint gap of the roof tile 1 at two places away from the eaves L1 and L2, so that the water on the surface of the waterproof layer 3 is discharged to the roof tile 1 The upper surface of the eaves and drips along the tile surface to the end of the eaves; the purpose of turning up the waterproof layer 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com