Water-base oil dirt cleaning agent and preparation method thereof

A grease cleaning agent, water-based technology, applied in the directions of detergent compounding agent, detergent composition, chemical instrument and method, etc., to achieve the effects of excellent decontamination, good skin compatibility and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: A water-based grease cleaner and a preparation method thereof.

[0031] See Table 1. The composition and weight percentage of the cleaning agent are: CAB 6%, AEO-9 2%, FMES 1%, AOS 2.5%, LAS 1%, triethanolamine 1.5%, trisodium citrate 2%, water margin.

[0032] A preparation method of a water-based grease cleaner includes the following steps.

[0033] a. Prepare the raw materials according to the formula. The raw materials include: CAB 6%, AEO-9 2%, FMES 1%, AOS 2.5%, LAS 2%, triethanolamine 1.5%, trisodium citrate 2%, and the balance of water.

[0034] b. Heat 2 / 3 of the water weighed in step (a) to 60°C. Under constant stirring, add the surfactants AOS and AEO-9 to dissolve first, dissolve the CAB with the remaining water and then add it, and finally add FMES, LAS.

[0035] c. After stirring for 1 hour at a constant temperature of 60°C, start to cool down to 40°C, then add triethanolamine and trisodium citrate, and continue to stir for 2 hours to make a high-effici...

Embodiment 2

[0037] Example 2: A water-based grease cleaner and a preparation method thereof.

[0038] Refer to Table 1, the composition and weight percentage of the cleaning agent are: CAB 4%, AEO-9 0.5%, FMES 2%, AOS 1.5%, LAS 0.5%, triethanolamine 3%, trisodium citrate 2.5%, water margin.

[0039] The steps of the preparation method are the same as in Example 1.

[0040] The sample prepared in Example 2 is a slightly white transparent clear solution with no delamination and no precipitation. Refer to the test method of "National Standard for Liquid Kitchen Oil Cleaner" to test the detergency of the sample, and its detergency reached 83.9%.

Embodiment 3

[0041] Example 3: A water-based grease cleaner and a preparation method thereof.

[0042] Referring to Table 1, the composition and weight percentage of the cleaning agent are: CAB 2%, FMES 3%, AOS 1%, triethanolamine 2%, trisodium citrate 3%, and water balance.

[0043] The steps of the preparation method are the same as in Example 1.

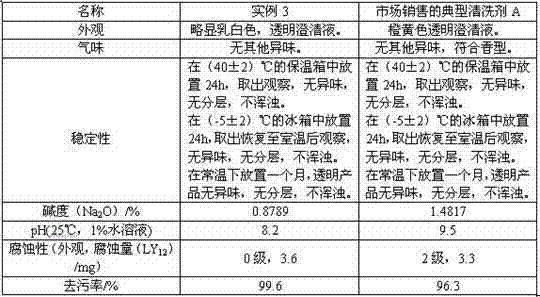

[0044] The sample prepared in Example 3 is a slightly milky white transparent and clear solution with no delamination and no precipitation. According to the test method of "National Standard for Liquid Kitchen Oil Cleaner", the detergency of the sample was tested, and its detergency reached 99.6%.

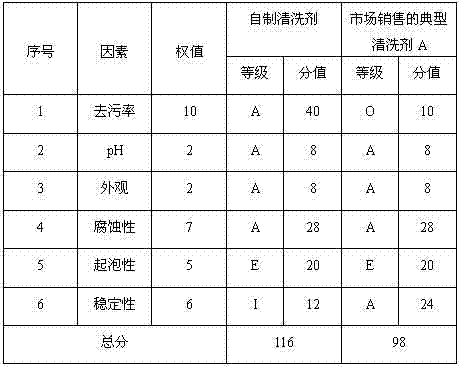

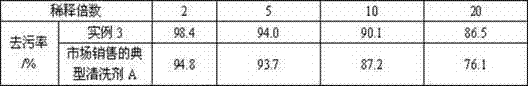

[0045] The physical and chemical properties of the typical cleaning agent A sold in the market and the sample of Example 3 are compared, see Table 2. Table 2 Comparison data of physical and chemical properties of self-made environmentally friendly water-based cleaning agent and typical cleaning agent A on the market

[0046]

[0047] By comparing appearan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com