A kind of multifunctional modified acrylic polyurethane rubber coating and preparation method thereof

A technology of acrylic polyurethane and rubber coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of gloss, fullness, distinct image, weather resistance, abrasion resistance, high and low temperature resistance, flexibility, and solvent resistance Contamination resistance and other comprehensive properties are not high, to achieve excellent flexibility, excellent wear resistance, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

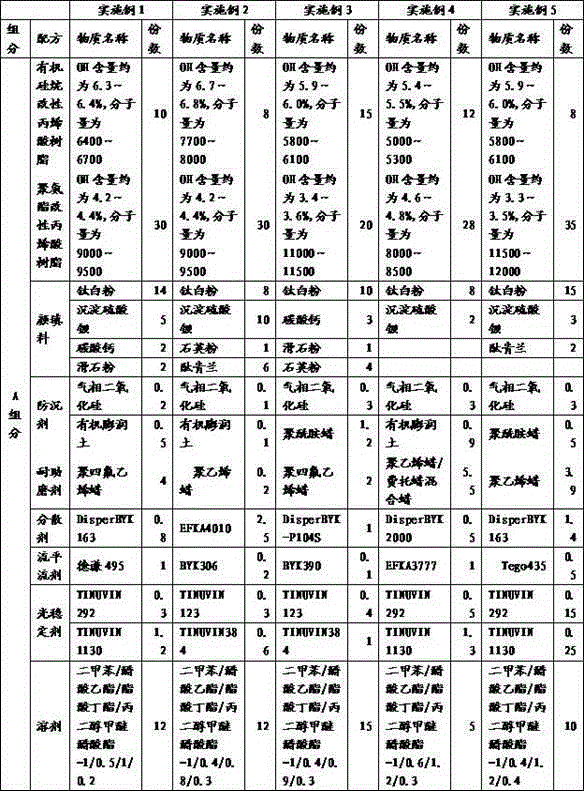

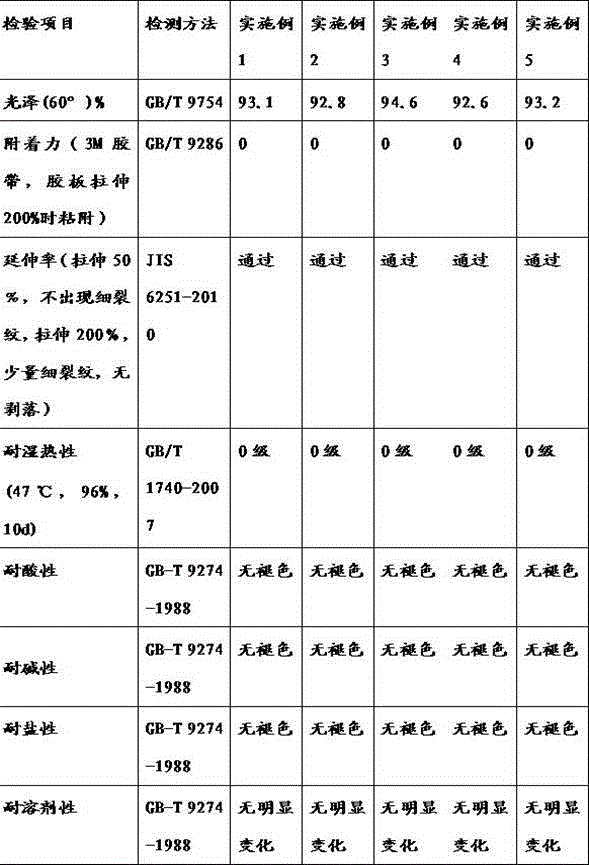

Examples

Embodiment 1

[0038] The preparation method of a white multifunctional modified acrylic polyurethane rubber coating is as follows: the preparation of component A: add the modified acrylic resin, anti-sedimentation agent, dispersant, and solvent into the container, and disperse for 20 minutes at a speed of 1000 rpm with a high-speed disperser , add pigments and fillers to disperse at high speed for 45 minutes, grind, control the fineness to no more than 20 μm, then add light stabilizer, wear-resistant additive, leveling agent to the ground paint, disperse at high speed for 60 minutes, mix evenly, and finally add some solvent to adjust When the viscosity reaches 70s, the A component that meets the requirements is obtained; the preparation of B component: mix the polyether-modified polycyanate prepolymer and the aliphatic isocyanate multimer evenly, and then the B component that meets the requirements is obtained. Components: When using, mix A and B components according to the molar ratio of OH...

Embodiment 2

[0040] A blue multifunctional modified acrylic polyurethane rubber paint production method is as follows: the preparation of component A: add modified acrylic resin, anti-sedimentation agent, dispersant, and solvent to the vessel, and disperse it with a high-speed disperser at a speed of 1200rpm 15 minutes, add pigments and fillers to disperse at high speed for 40 minutes, grind, control the fineness to no more than 20 μm, then add light stabilizer, wear-resistant additive, leveling agent to the ground paint, disperse at high speed for 60 minutes, mix evenly, and finally add some solvent Adjust the viscosity to 75s to obtain the A component that meets the requirements; the preparation of the B component: mix the polyether-modified polycyanate prepolymer and the aliphatic isocyanate multimer evenly to obtain the A component that meets the requirements Component B; when used, mix components A and B according to the molar ratio of 0.95 between the OH contained in the modified acry...

Embodiment 3

[0042]The preparation method of a white multifunctional modified acrylic polyurethane rubber coating is as follows: the preparation of component A: add the modified acrylic resin, anti-sedimentation agent, dispersant, and solvent into the container, and disperse for 20 minutes at a speed of 1200 rpm with a high-speed disperser , add pigments and fillers to disperse at high speed for 40 minutes, grind, control the fineness to no more than 20 μm, then add light stabilizer, wear-resistant additive, leveling agent to the ground paint, disperse at high speed for 45 minutes, mix evenly, and finally add some solvent to adjust Viscosity reaches 90s, that is, the A component that meets the requirements is obtained; the preparation of B component: mix the polyether-modified polycyanate prepolymer and the aliphatic isocyanate multimer evenly, that is, the B component that meets the requirements is obtained. Components: When using, mix A and B components according to the molar ratio of OH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com