HIPS composite, and preparation method and application thereof

A technology of composite materials and mixtures, which is applied in the field of engineering plastics, can solve the problems that HIPS composite materials cannot have good mechanical properties and antistatic properties at the same time, and achieve excellent antistatic effects, high production efficiency, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention further provides the method for preparing the above-mentioned HIPS composite material, comprising the following steps:

[0025] Step S01, providing raw materials:

[0026] Provide the HIPS resin, SBS resin, antistatic agent, lubricant and antioxidant according to the formula;

[0027] Step S02, mixing:

[0028] Mixing the HIPS resin, SBS resin, antistatic agent, lubricant and antioxidant to obtain a mixture;

[0029] Step S03, melt extrusion:

[0030] The mixture is extruded to obtain a HIPS composite material.

[0031] Specifically, in step S01, the HIPS resin, SBS resin, antistatic agent, lubricant, and antioxidant are the same as those described above, and will not be repeated here.

[0032] In step S02, it is divided into the following two steps:

[0033] mixing the HIPS resin and the SBS resin to obtain the first mixture;

[0034] mixing the antistatic agent, lubricant and antioxidant to obtain a second mixture;

[003...

Embodiment HI

[0043] The preparation method of the HIPS composite material of the embodiment of the present invention comprises the following steps:

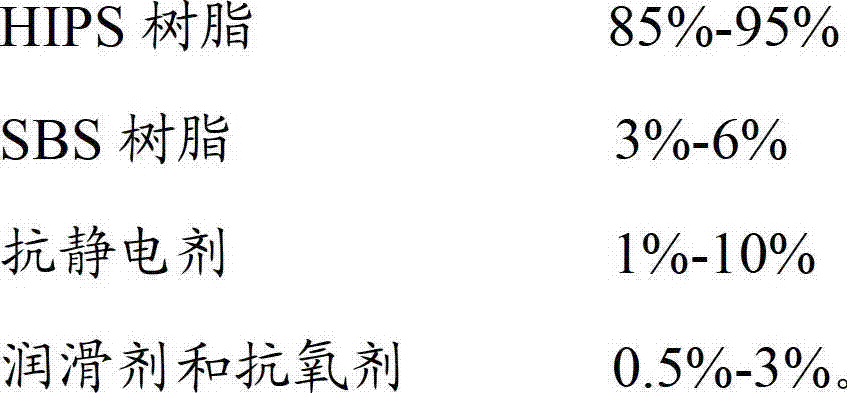

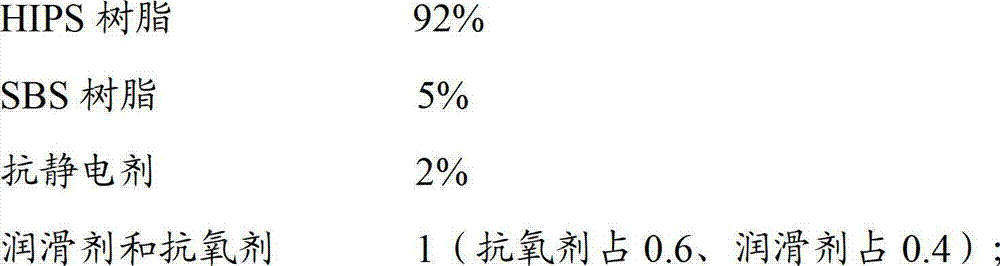

[0044] Weigh the components in the following weight percentages:

[0045]

[0046] mixing HIPS resin and SBS resin to obtain a first mixture, and then mixing an antistatic agent, a lubricant and an antioxidant to obtain a second mixture;

[0047] After mixing the first mixture and the second mixture uniformly in a high-speed mixer, move them into a twin-screw extruder to melt and blend at 150-220°C, with a pressure of 20-35Mpa, and the materials stay for 2 minutes, and then discharged, after extrusion Cool, dry and cut into pellets. The extrusion process is as follows: the temperature of the first zone is 150-160°C, the temperature of the second zone is 170-180°C, the temperature of the third zone is 170-180°C, the temperature of the fourth zone is 180-190°C, the temperature of the fifth zone is 190-200°C, the temperature of the sixth zon...

Embodiment 2

[0049] The preparation method of the HIPS composite material of the embodiment of the present invention comprises the following steps:

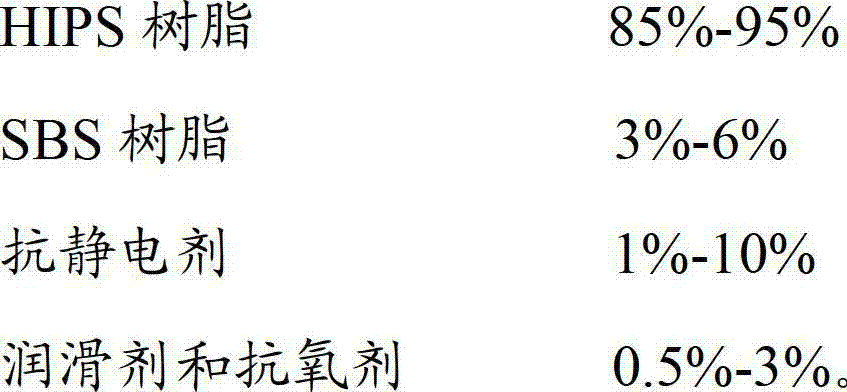

[0050] Weigh the components in the following weight percentages:

[0051]

[0052] mixing HIPS resin and SBS resin to obtain a first mixture, and then mixing an antistatic agent, a lubricant and an antioxidant to obtain a second mixture;

[0053] After mixing the first mixture and the second mixture uniformly in a high-speed mixer, move them into a twin-screw extruder to melt and blend at 150-220°C, with a pressure of 20-35Mpa, and the materials stay for 2 minutes, and then discharged, after extrusion Cooling, drying and dicing to get the finished product. The extrusion process is as follows: the temperature of the first zone is 150-160°C, the temperature of the second zone is 170-180°C, the temperature of the third zone is 170-180°C, the temperature of the fourth zone is 180-190°C, the temperature of the fifth zone is 190-200°C, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com