Antistatic antibacterial far-infrared moisture-absorbing and quick-drying down fabric manufacturing method

A down fabric, moisture-absorbing and quick-drying technology, applied in conductive/antistatic filament manufacturing, chemical instruments and methods, jackets, etc. To achieve the effect of ensuring thermal insulation performance, soft hand feel and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

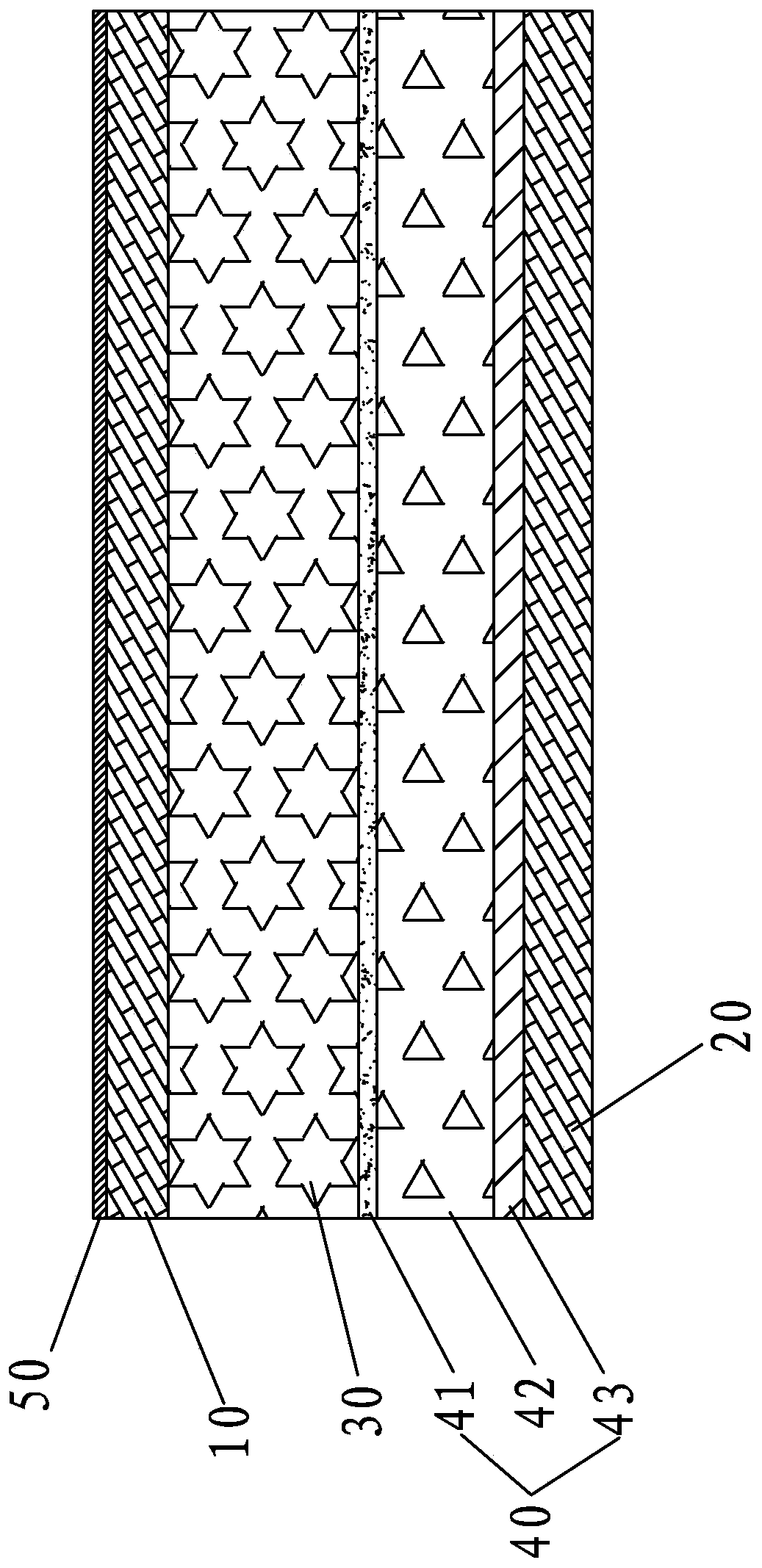

[0040] refer to Figure 1 to Figure 4 , antistatic, antibacterial, far-infrared, moisture-absorbing and quick-drying down layer 30 fabric production method, down layer 30 fabric includes a fabric body, the side of the fabric body close to the human skin is the outside, and the opposite side is the inside, the fabric body It includes a surface layer 10 , an inner layer 20 and a down layer 30 formed between the surface layer 10 and the inner layer 20 .

[0041] The present invention also includes a windproof and heat-locking layer 40, the surface layer 10 and the windproof and heat-locking layer 40 are sewed together by sutures to form an accommodating channel for filling the down layer 30, and the down is filled into the accommodating channel Down layer 30 is formed in the middle. The wind-proof and heat-locking laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com