Biodegradable thin film and preparation method thereof

A technology of biodegradation and biodegradable resin, which is applied in the field of biodegradable film and its preparation, can solve the problems of crop yield reduction, river blockage, and land that cannot be cultivated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method comprises the following steps,

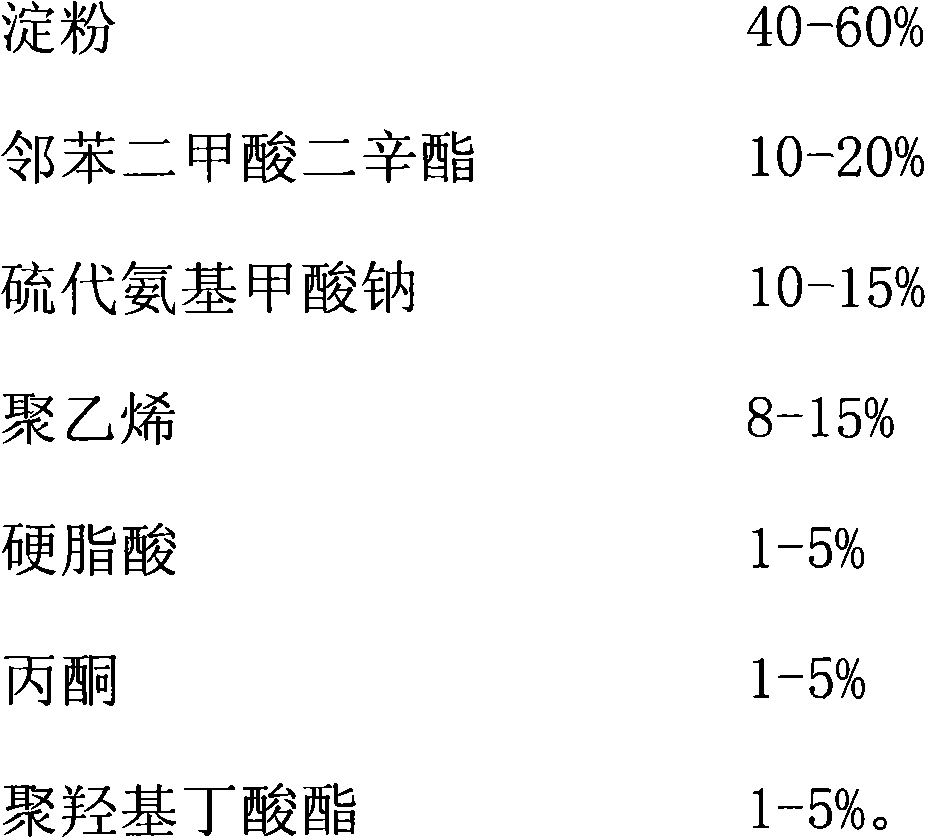

[0021] (1) Prepare materials according to the following formula:

[0022]

[0023] (2) The components are added into the mixer and stirred evenly;

[0024] (3) adding the above-mentioned materials into a twin-screw granulator for kneading, melting, extruding, cooling, and pelletizing to obtain cylindrical granules with a length of 3-5mm and a diameter of 3-5mm at the bottom;

[0025] (4) Add the above-mentioned biodegradable resin particles into a film blowing machine to make a biodegradable film.

Embodiment 2

[0027] The preparation method comprises the following steps,

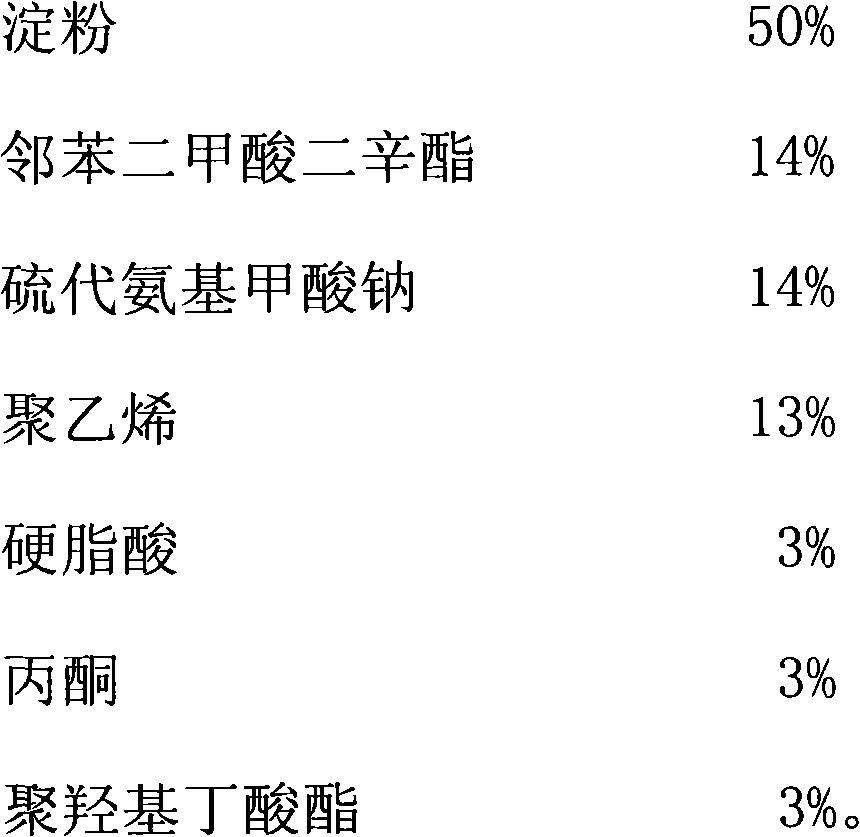

[0028] (1) Prepare materials according to the following formula:

[0029]

[0030] (2) The components are added into the mixer and stirred evenly;

[0031] (3) adding the above-mentioned materials into a twin-screw granulator for kneading, melting, extruding, cooling, and pelletizing to obtain cylindrical granules with a length of 3-5mm and a diameter of 3-5mm at the bottom;

[0032] (4) Add the above-mentioned biodegradable resin particles into a film blowing machine to make a biodegradable film.

Embodiment 3

[0034] The preparation method comprises the following steps,

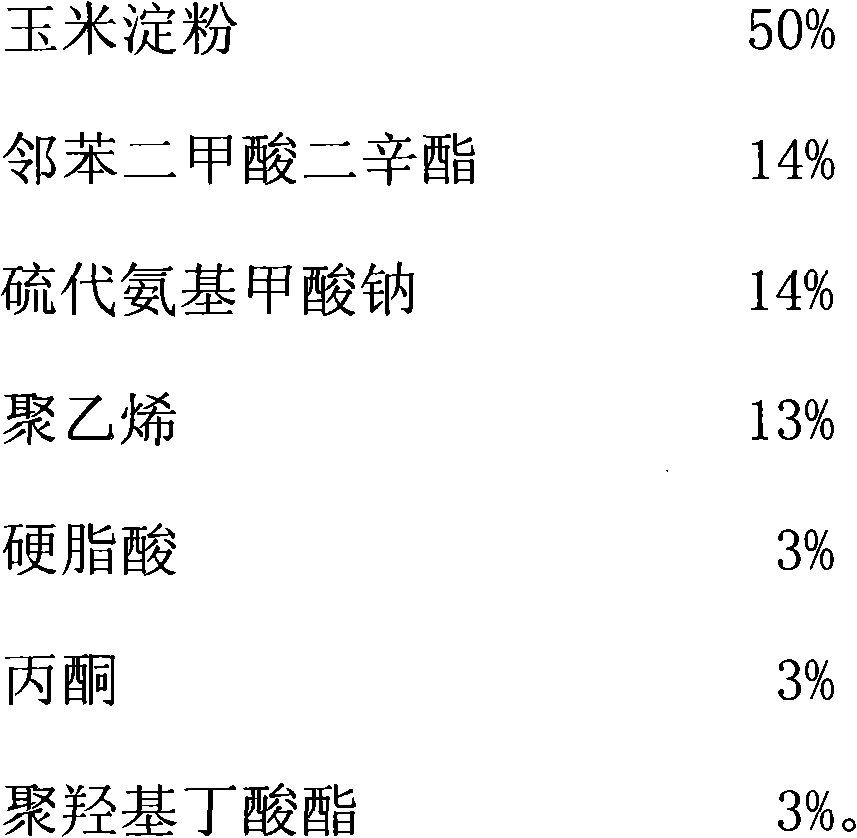

[0035] (1) Prepare materials according to the following formula:

[0036]

[0037]

[0038] (2) The components are added into the mixer and stirred evenly;

[0039] (3) adding the above-mentioned materials into a twin-screw granulator for kneading, melting, extruding, cooling, and pelletizing to obtain cylindrical granules with a length of 3-5mm and a diameter of 3-5mm at the bottom;

[0040] (4) Add the above-mentioned biodegradable resin particles into a film blowing machine to make a biodegradable film.

[0041] The National Synthetic Resin and Plastics Quality Supervision and Inspection Center has carried out an inspection of the degradation effect on the biodegradable film of the present invention at an ultraviolet irradiation temperature of 60°C and an intensity of 1000 μw / cm2. The results of the inspection are:

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com