Compound feed for improving production performance of laying hen and egg quality

A compound feed and laying hen production technology, which is applied in the field of compound feed to improve the production performance and egg quality of laying hens, can solve the problems affecting the treatment and genetics of human diseases, the difficulty of earning foreign exchange from the export of animal products, and the economic benefits of the breeding industry, etc. The effect of improving feed conversion rate, improving egg quality and increasing egg weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A compound feed for improving the production performance and egg quality of laying hens, the composition of which is as follows in parts by weight of raw materials:

[0028] 60.5 parts of corn, 0.55 parts of lard, 13.5 parts of soybean meal, 2.8 parts of cotton meal, 3.2 parts of rapeseed cake, 3 parts of peanut meal, 5.5 parts of sprayed bran, 9.3 parts of stone powder, 0.5 parts of calcium hydrogen phosphate, 0.04 parts of lysine 0.06 part of methionine, 0.02 part of liquid phytase, 0.03 part of liquid xylanase, and 1 part of premix. Wherein the premix consists of the following components: 0.02 parts of multivitamins, 0.08 parts of compound trace elements, 0.04 parts of Bacillus subtilis preparations, 0.015 parts of solid phytase, 0.033 parts of methionine, 0.3 parts of table salt, 0.005 parts of antioxidants, baking soda 0.15 parts, Yuanmingfen 0.15 parts, betaine 0.016 parts, rice bran 0.191 parts.

[0029] How to use: It is used to feed laying hens during the layi...

Embodiment 2

[0031] A compound feed for improving the production performance and egg quality of laying hens, the composition of which is as follows in parts by weight of raw materials:

[0032] 59.5 parts of corn, 0.6 parts of lard, 13 parts of soybean meal, 1.8 parts of cotton meal, 2.5 parts of rapeseed cake, 4 parts of peanut meal, 7.5 parts of sprayed bran, 9.2 parts of stone powder, 0.7 parts of calcium hydrogen phosphate, 0.065 parts of lysine 0.055 parts of methionine, 0.035 parts of liquid phytase, 0.045 parts of liquid xylanase, and 1 part of premix. The premix consists of the following components: 0.025 parts of multivitamins, 0.085 parts of compound trace elements, 0.05 parts of Bacillus subtilis preparation, 0.02 parts of solid phytase, 0.035 parts of methionine, 0.2 parts of table salt, 0.006 parts of antioxidants, baking soda 0.1 part, Yuanmingfen 0.1 part, betaine 0.017 part, rice bran 0.362 part.

[0033] Using method is the same as embodiment 1.

Embodiment 3

[0035] A compound feed for improving the production performance and egg quality of laying hens, the composition of which is as follows in parts by weight of raw materials:

[0036] 61 parts of corn, 0.46 parts of lard, 16 parts of soybean meal, 1.6 parts of cotton meal, 1.8 parts of rapeseed cake, 2 parts of peanut meal, 6 parts of sprayed bran, 9.1 parts of stone powder, 0.9 parts of calcium hydrogen phosphate, 0.02 parts of lysine 0.05 part of methionine, 0.03 part of liquid phytase, 0.04 part of liquid xylanase, and 1 part of premix. The premix consists of the following components: 0.015 parts of multivitamins, 0.075 parts of compound trace elements, 0.03 parts of Bacillus subtilis preparation, 0.01 parts of solid phytase, 0.03 parts of methionine, 0.4 parts of table salt, 0.004 parts of antioxidants, baking soda 0.2 parts, Yuanmingfen 0.2 parts, betaine 0.015 parts, rice bran 0.021 parts.

[0037] Using method is the same as embodiment 1.

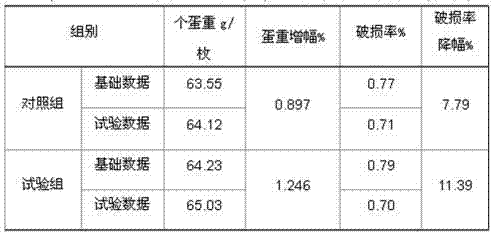

[0038] Effect example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com