High-accuracy temperature compensation crystal oscillator system and operational method thereof

A crystal oscillator and temperature compensation technology, which is applied to power oscillators, electrical components, etc., to achieve the effect of improving work efficiency and temperature compensation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will become clearer through the description of the following embodiments in conjunction with the accompanying drawings, which are used to explain the embodiments of the present invention.

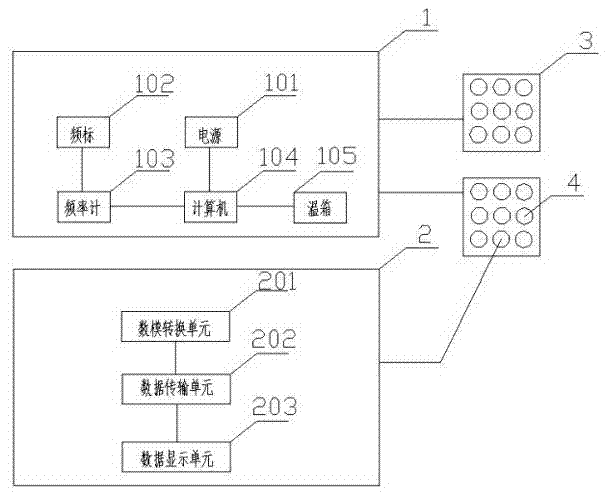

[0024] see figure 1 The hardware structure of this high-precision temperature-compensated crystal oscillator system is composed of a control unit 1, a data transmission and display unit 2, a test control board 3, and a crystal oscillator 4. The control unit 1 is composed of a power supply 101, a frequency standard 102, and a frequency counter. 103 , a computer 104 , and a thermostat 105 , and the data transmission and display unit 2 is composed of a digital-to-analog conversion unit 201 , a data transmission unit 202 , and a data display unit 203 .

[0025] A test control board 3 is placed inside the thermostat 105, a crystal oscillator 4 is arranged on the test control board 3, and a DIO card and a GPIB card are inserted into the main board of the computer 104 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com