A new metamaterial

A metamaterial, a new type of technology, applied in the field of materials, which can solve the problems of high dielectric constant and inability to change the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

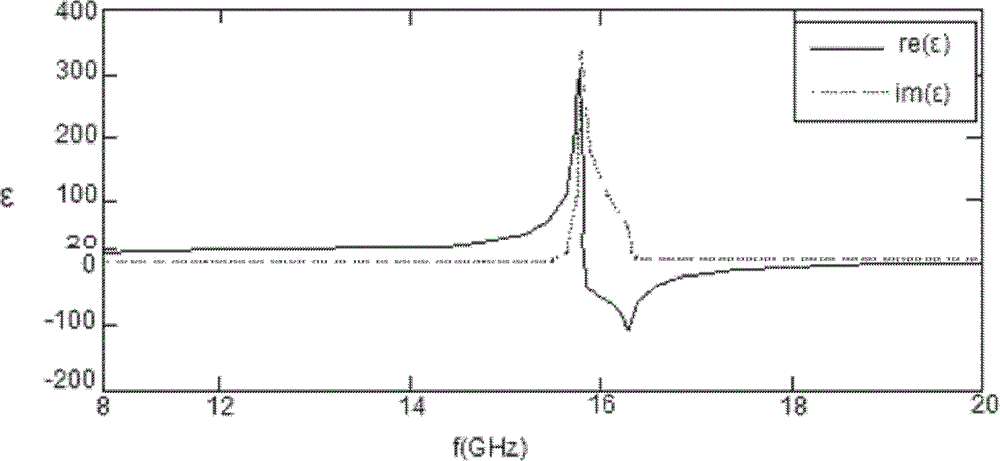

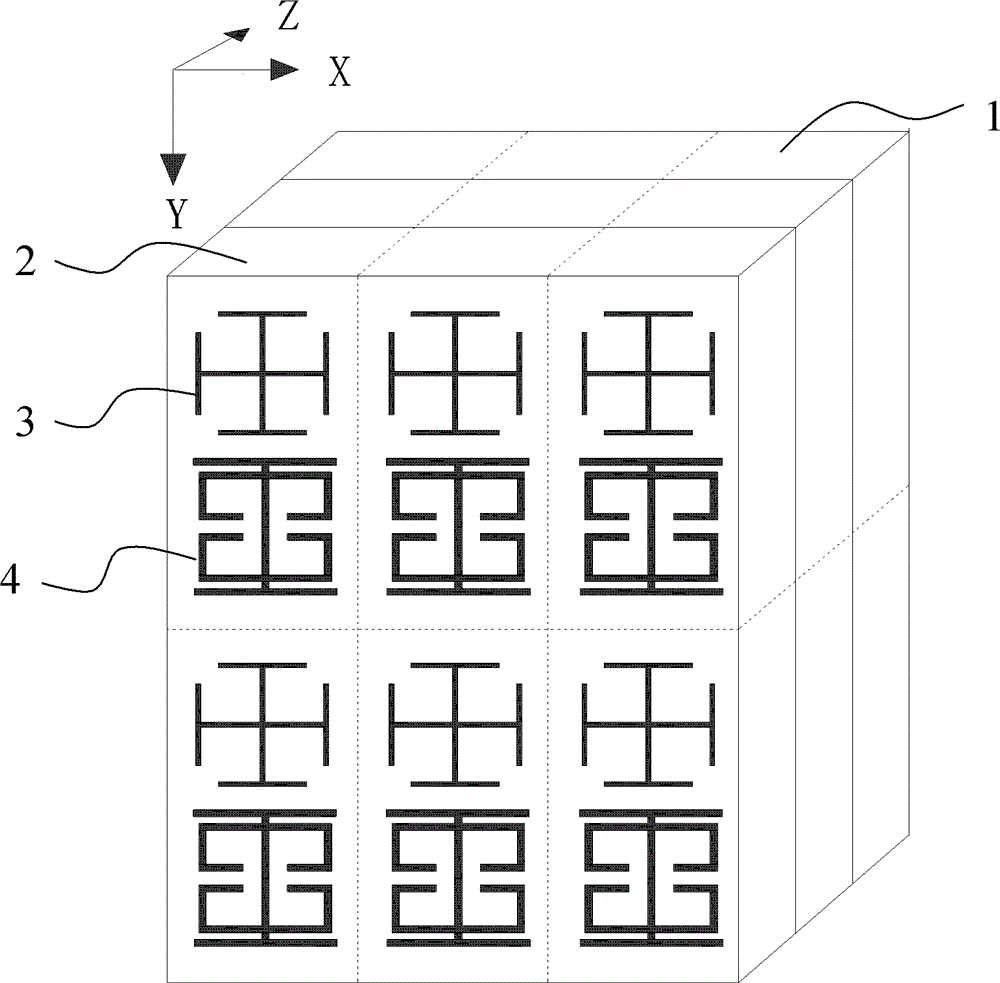

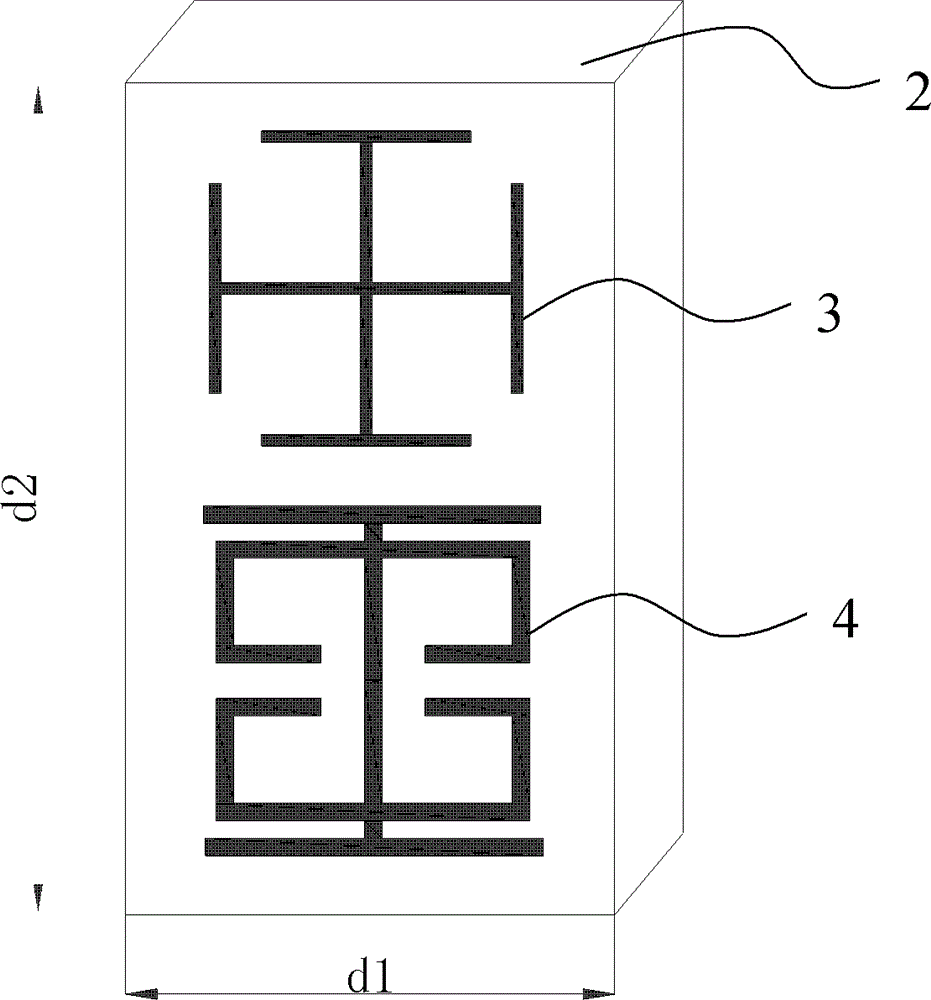

[0033] When the first artificial microstructure 3 such as Figure 4 As shown, a1=0.4 mm, a2=0.1 mm, a3=0.8 mm, the second artificial microstructure 4 is as Figure 5 As shown, b1=1.8 mm, b2=0.1 mm, b3=0.7 mm, b4=0.6 mm, the substrate unit is as image 3 As shown, d1 = 2 mm, d2 = 4 mm, and the thickness is 0.4 mm. The simulation diagram obtained by using the above parameters is as follows Figure 7 shown by Figure 7 The solid line in the figure shows that the metamaterial has multiple resonance peaks, and the dielectric constant gradually increases from zero in a certain frequency band (20.3GHz-22.8GHz, 30GHz-34.3GHz), and the dielectric constant of 0-17GHz in another frequency band The constant change is relatively stable and has a large value, and it can be seen from the dotted line that the imaginary part of the corresponding dielectric constant is close to zero in the above-mentioned frequency band with a small dielectric constant, so the loss is also low.

Embodiment 2

[0035] The difference from Embodiment 1 lies in the size of the first artificial microstructure 3. The first artificial microstructure 3 after the size increase is as follows: Figure 6 As shown, c1=1.2 mm, c2=0.1 mm, c3=0.8 mm, the second artificial microstructure 4 is as Figure 5 As shown, b1=1.8 mm, b2=0.1 mm, b3=0.7 mm, b4=0.6 mm, such as image 3 For the substrate unit shown, d1=2 mm, d2=4 mm, and the thickness is 0.4 mm, the simulation diagram obtained by using the above parameters is as follows Figure 8 shown by Figure 8The solid line in the figure shows that the material still has multiple resonance peaks, and the dielectric constant gradually increases from zero in a certain frequency band (16.7GHz-19.3GHz, 27.1GHz-34.1GHz), and it can be seen from the dotted line that when the dielectric constant is relatively The imaginary part of the corresponding dielectric constant in the small above-mentioned frequency band is close to zero, so the loss is also low.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com