Vertical transition structure among three-dimensional multi-chip component boards

A multi-chip component and vertical transition technology, which is applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problem of occupying laminated circuit boards, side circuits and horizontal circuits with high process requirements and restricting the density of chip components and assembly efficiency to achieve the effect of ensuring realizability and alleviating the strict requirements of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

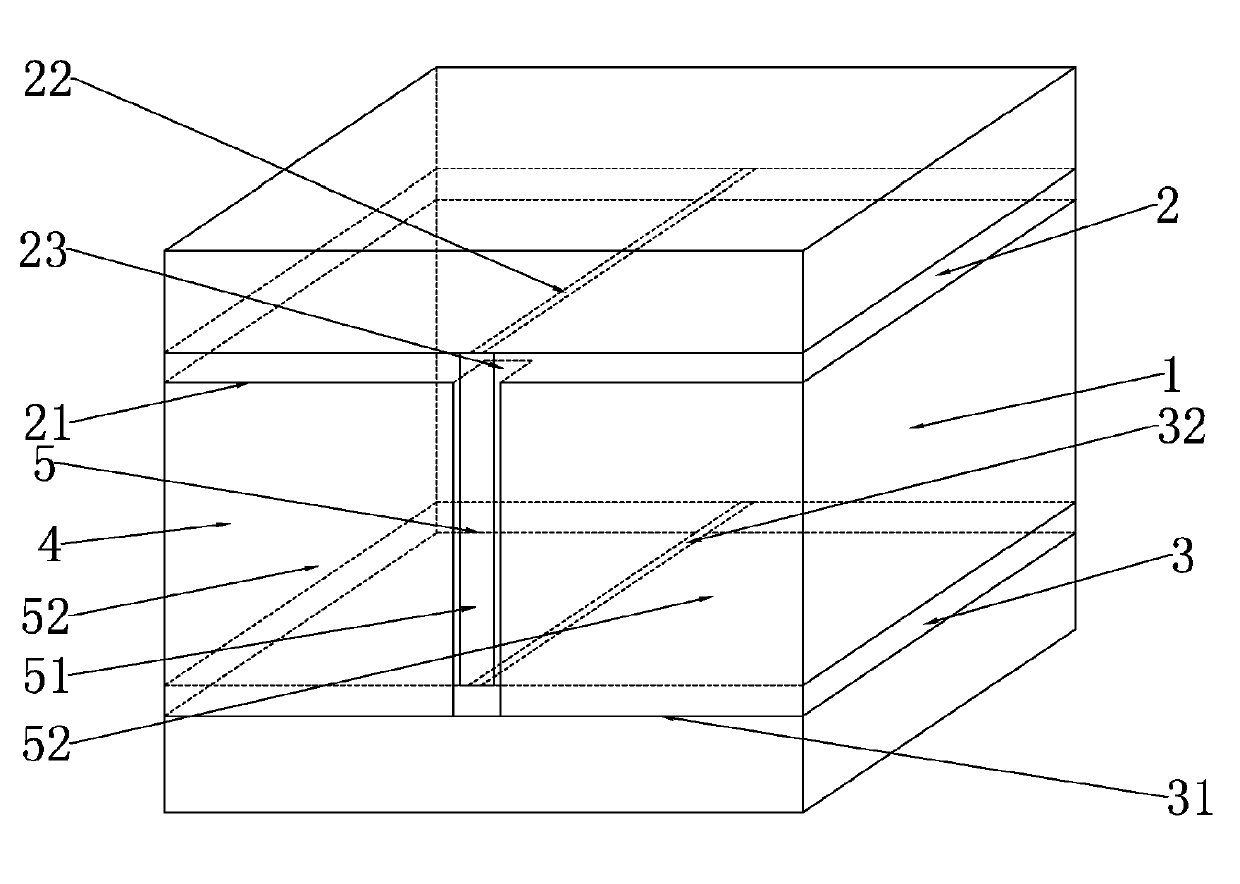

[0016] The vertical transition structure between the three-dimensional multi-chip component boards of the present invention is specifically as follows: the upper layer circuit board 2 and the lower layer circuit board 3 are stacked and packaged in the three-dimensional component module 1, and the upper layer circuit board 2 has an upper layer microstrip line conduction belt 22, The lower layer circuit board 3 has a lower layer of microstrip line conduction tape 32, and the upper layer of microstrip line conduction tape 22 and the lower layer of microstrip line conduction tape 32 are all to the edges of the circuit boards 2 and 3 to ensure that the upper layer of microstrip line conduction tape 22 and the lower microstrip line conduction strip 32 can be well connected with the side surface circuit; the side surface of the three-dimensional component module 1 adopts a copl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com