Preparation method for anti-fingerprint film and anti-fingerprint film prepared by method

An anti-fingerprint and film technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of easy sticking of fingerprints and oil stains on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

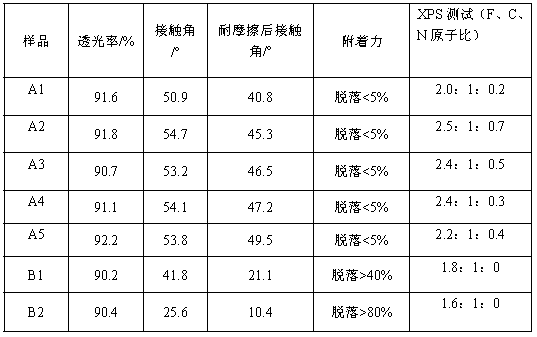

[0009] The preparation method of the anti-fingerprint film disclosed by the present invention adopts magnetron sputtering to form an anti-fingerprint film on the surface of the substrate, the target material used in the magnetron sputtering is a fluorine-containing organic substance, and the reaction gas is filled in the magnetron sputtering process , the reaction gas is CF 4 and N 2 of mixed gas. Control CF when feeding reaction gas 4 and N 2 The flow ratio of the gas is 0.1-1:1, and the flow rate of the two gases is between 100-500 sccm. Magnetron sputtering makes the atoms in the target and the reaction gas deposit on the surface of the substrate to form a thin film containing three atoms of F, C and N, which not only significantly improves the anti-fingerprint effect, but also has high light transmittance and Wear resistance, and good adhesion. The substrate can be glass or metal.

[0010] The present invention uses fluorine-containing organic substances as target ma...

Embodiment 1

[0020] Wash the glass substrate with water in a 20KHz ultrasonic instrument for 20 minutes, put the cleaned glass substrate into the vacuum furnace of the magnetron sputtering apparatus, close the furnace door, and turn on the vacuum pump to evacuate to 10 -2 Pa, argon gas is introduced, the flow rate of argon gas is 200 sccm, the vacuum degree is adjusted to 1.5Pa, the bias voltage is 400V, the duty ratio is 35%, the sputtering power is 800W, and the glass substrate is subjected to ion bombardment treatment. for 5min. Then put the prefabricated target into the vacuum chamber, close the furnace door and evacuate to a vacuum degree of 10 -2 Pa, through the reaction gas CF 4 and N 2 , CF 4 The flow rate is 100 sccm, N 2 The flow rate is 330 sccm, adjust the CF 4 and N 2 The ratio is 0.3:1, the vacuum degree is 0.8Pa, the RF power is turned on, the power of the target power is 800W, the bias voltage is 50V, the duty cycle is 20%, and the time is 15min. After cooling for 3 ...

Embodiment 2

[0022] Wash the glass substrate with water in a 20KHz ultrasonic instrument for 20 minutes, put the cleaned glass substrate into a vacuum furnace, close the furnace door, turn on the vacuum pump to evacuate, and evacuate to 10 -2 Pa, argon gas is introduced, the flow rate of argon gas is 250 sccm, the vacuum degree is adjusted to 1.5Pa, the bias voltage is 500V, the duty ratio is 40%, the sputtering power is 600W, and the glass substrate is subjected to ion bombardment treatment, time for 3min. Then put the prefabricated target into the vacuum chamber, close the furnace door and evacuate to a vacuum degree of 10 -2 Pa, through the reaction gas CF 4 and N 2 , CF 4 The flow rate is 300 sccm, N 2 The flow rate is 300 sccm, adjust the CF 4 and N 2 The ratio is 1:1, the vacuum degree is 0.8Pa, the RF power is turned on, the power of the target power is 1000W, the bias voltage is 100V, the duty cycle is 30%, and the time is 8min. After cooling for 3 minutes, take it out of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com