Stone with functional thin film layer and manufacturing method thereof

A manufacturing method and technology of thin film layer, applied in the field of stone manufacturing, can solve the problems of surface wear resistance, corrosion resistance not ideal, decoration not diverse enough, influence the service life of buildings and building color changes, etc. The effect of cost reduction and more choice space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

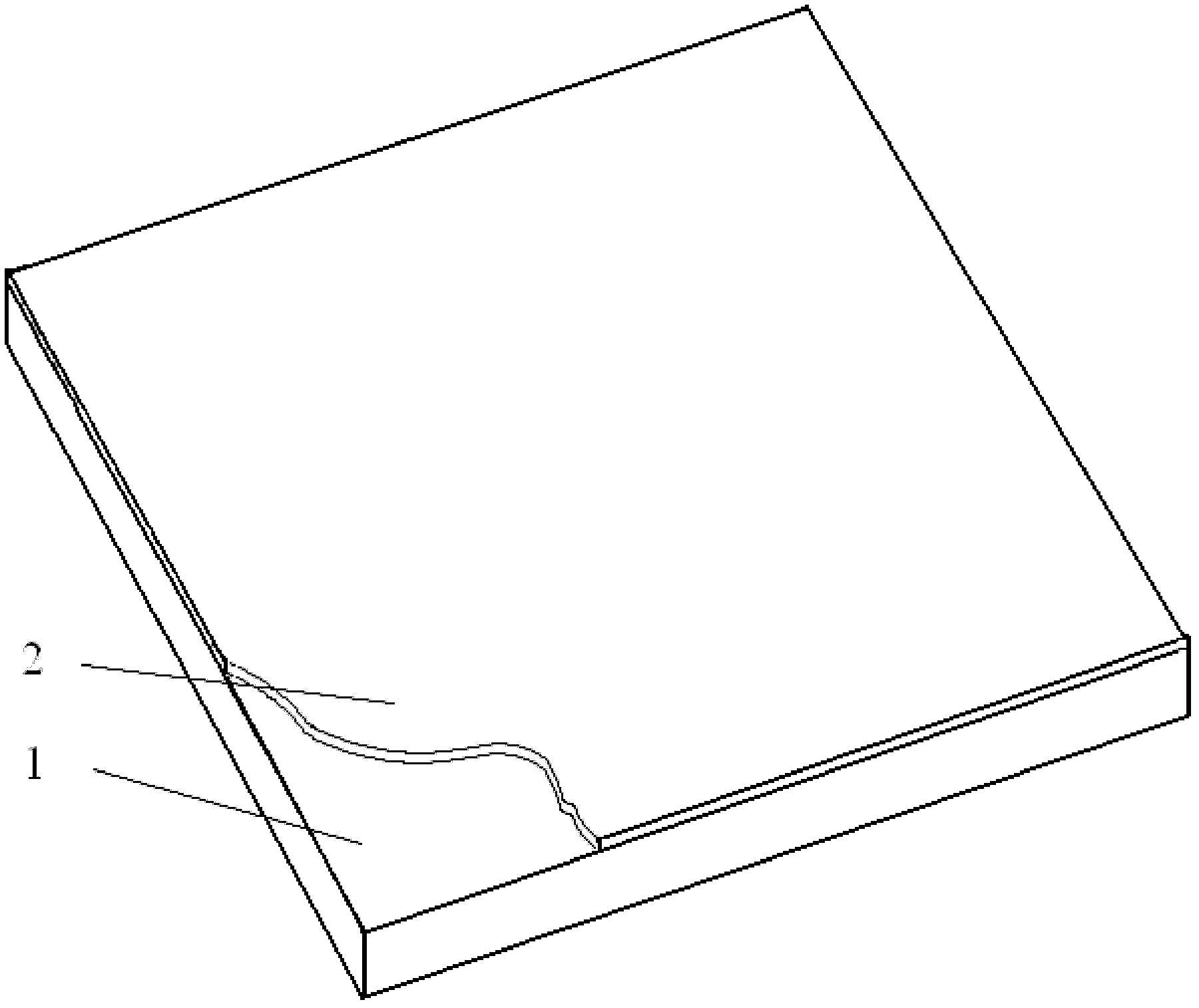

Image

Examples

Embodiment 1

[0015] Example 1: The flat natural stone is used as the base material, and gold is used as the target material, and they are sent into the magnetron sputtering operation chamber together, and sputtering and adsorption are generated according to the magnetron sputtering method, and the gold is attached to the surface of the stone And spread to the inside to form a gold film. Thus, the stone material with the functional film layer of the present invention is obtained, so that the surface of the stone material has the decorative performance of gold. Especially when the thickness of the film layer is very thin, the texture on the surface of the natural stone is still faintly visible, and the decorative effect is excellent.

Embodiment 2

[0016] Example 2: The flat-shaped natural stone is used as the base material, and the titanium-aluminum alloy is used as the target material, and they are sent into the magnetron sputtering operation room together. According to the magnetron sputtering method, sputtering and adsorption are generated, and the titanium-aluminum alloy is attached to the The surface of the above-mentioned stone and diffuses to the inside to form a titanium or titanium alloy film. Thus, the stone material with a functional thin film layer of the present invention is obtained. Because the titanium aluminum alloy has the characteristics of high strength, good corrosion resistance, and high heat resistance, the surface of the stone material has the characteristics of titanium aluminum alloy.

Embodiment 3

[0017] Example 3: Using natural stone as the base material and silicon nitride as the target material, they are sent together into the ion beam sputtering operation room. According to the ion beam sputtering method, sputtering and adsorption occur, and silicon nitride is attached to the stone material On the surface, a silicon nitride film is formed. Thus, the stone material with the functional film layer of the present invention is obtained, which is white or off-white, so that the surface of the stone material has the wear-resistant property of silicon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com