Powder dust conveying method and system device for powder dust field

A conveying system, a technology for ash, applied in the directions of liquid distribution, conveying or transfer devices, devices for controlling liquid flow, distribution devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

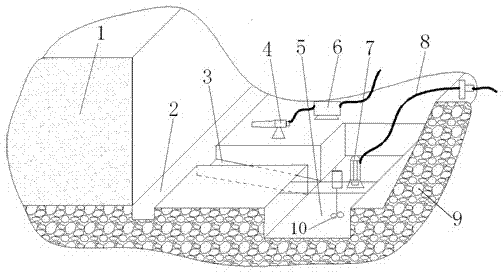

[0029] Such as figure 2 As shown, a fly ash conveying system includes a high-pressure hydraulic impact device 4, a water slurry stirring device 7 and a water slurry conveying device 8; the high-pressure hydraulic impact device impacts the fly ash block to make the fly ash block into a water slurry , and then use the water slurry stirring device 10 to stir the water slurry powder and ash block to make it into a water slurry suitable for transportation, and then use the water slurry delivery device 7 to transport the water slurry to the designated storage point through the pipeline 8 as the next step. preparations.

[0030] Further, the high-pressure hydraulic impact device 4 is a high-pressure water gun, and the high-pressure water gun is provided with high-pressure water by the water supply device 6, and uses high-pressure water to disperse the powder ash that has become agglomerated into a water slurry, and then after the pulping treatment , and use the mud pump to transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com