Dope for spinning lyocell, method for preparing a lyocell filament fiber using same, and method for preparing a lyocell staple fiber using same

A technology of soluble fiber and filament fiber, which is applied in the direction of single-component cellulose rayon, rayon made of viscose, spinning machine, etc., which can solve complex manufacturing process, fabric weight reduction, surface touch Product quality decline and other problems, to achieve the effect of excellent final product quality and excellent surface touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

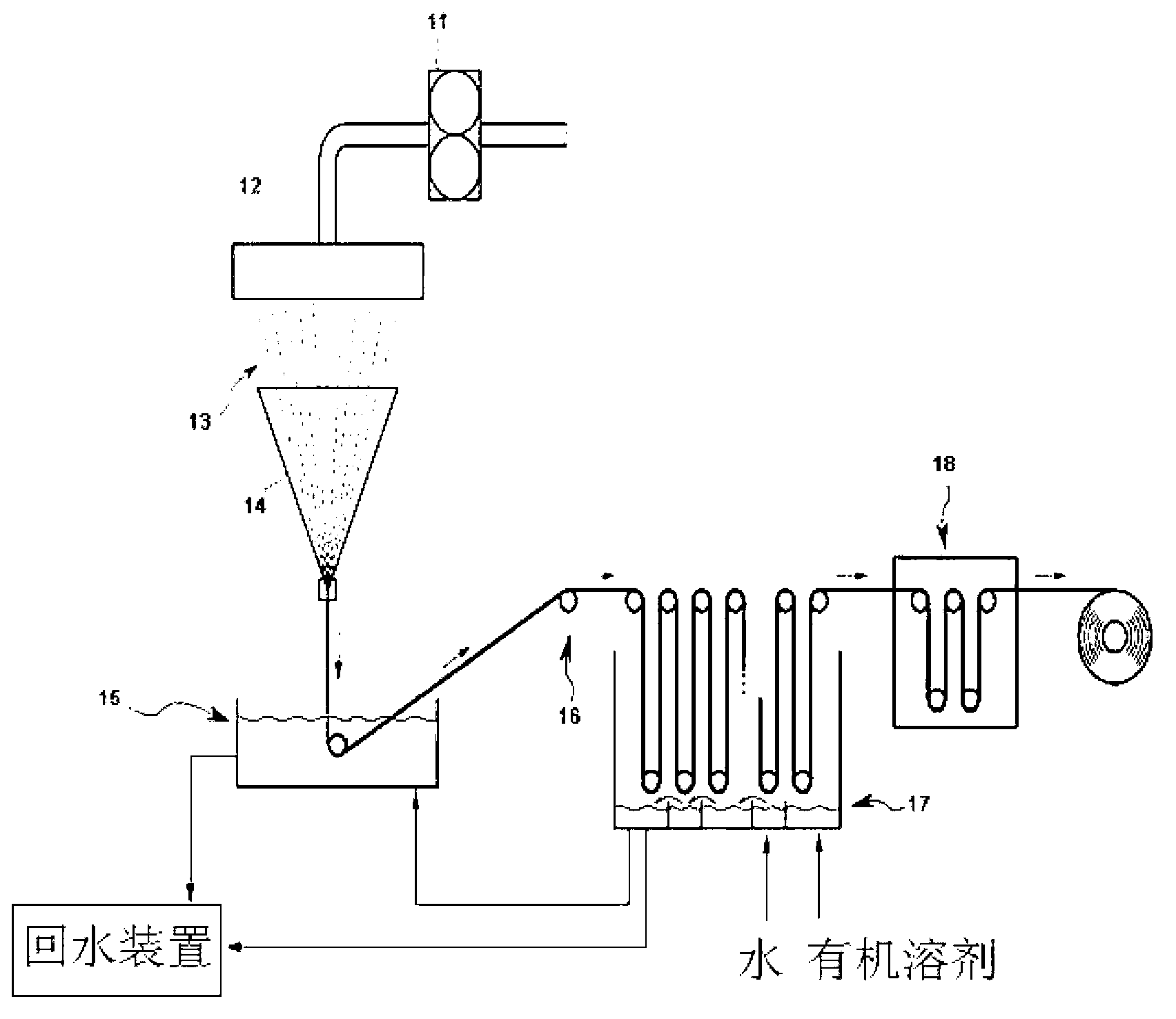

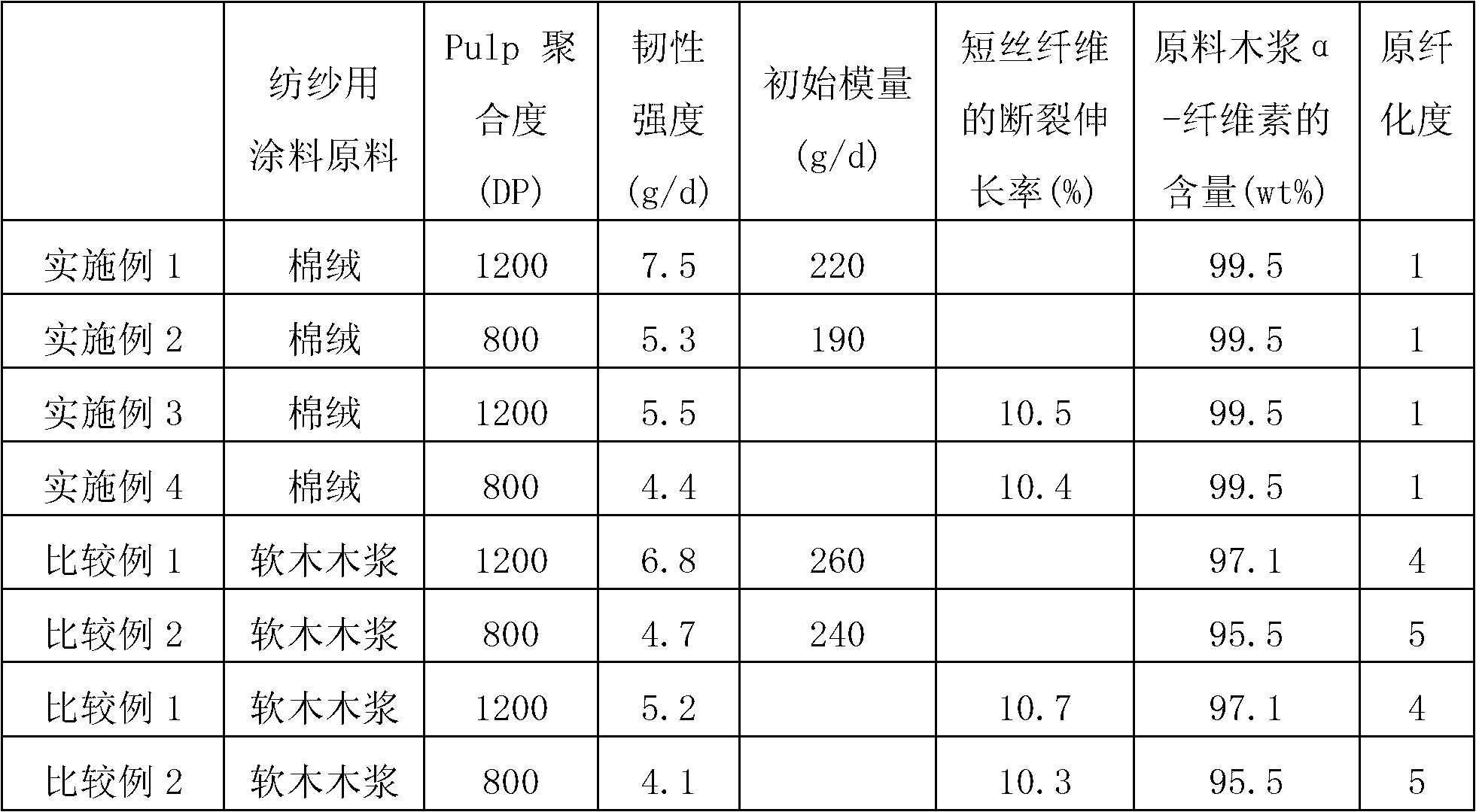

[0079] Example 1: Manufacturing Dissolvable Filament Fibers Using Cotton Linter Slurry

[0080] Put the cotton linter slurry (provided by Mint) with a degree of polymerization (DP) of 1200 into a pulverizer equipped with a 100-mesh filter to produce a slurry powder with a diameter of less than 1700μ.

[0081] The above-mentioned slurry powder was swollen in a 50% by weight NMMO aqueous solution. At this time, the content of the slurry in the NMMO aqueous solution was 6% by weight, and an oxidation inhibitor was added in an amount of 0.01% by weight relative to the cotton linter.

[0082] While maintaining the internal temperature of the swollen slurry at 90°C, inject it into a mixer with an absolute pressure of 50mmHg at a rate of 16kg / hour using a rotary piston pump, and remove excess water to make 50% by weight of NMMO The aqueous solution was an 89% by weight NMMO aqueous solution, and after the slurry was completely dissolved, the spinning dope was discharged through the ...

Embodiment 2

[0086] Example 2: Manufacturing Dissolvable Filament Fibers Using Cotton Linter Slurry

[0087] Dissolving multifilament fiber precursors were obtained in the same manner as in Example 1 except that a cotton linter slurry having a degree of polymerization (DP) of 800 was used.

Embodiment 3

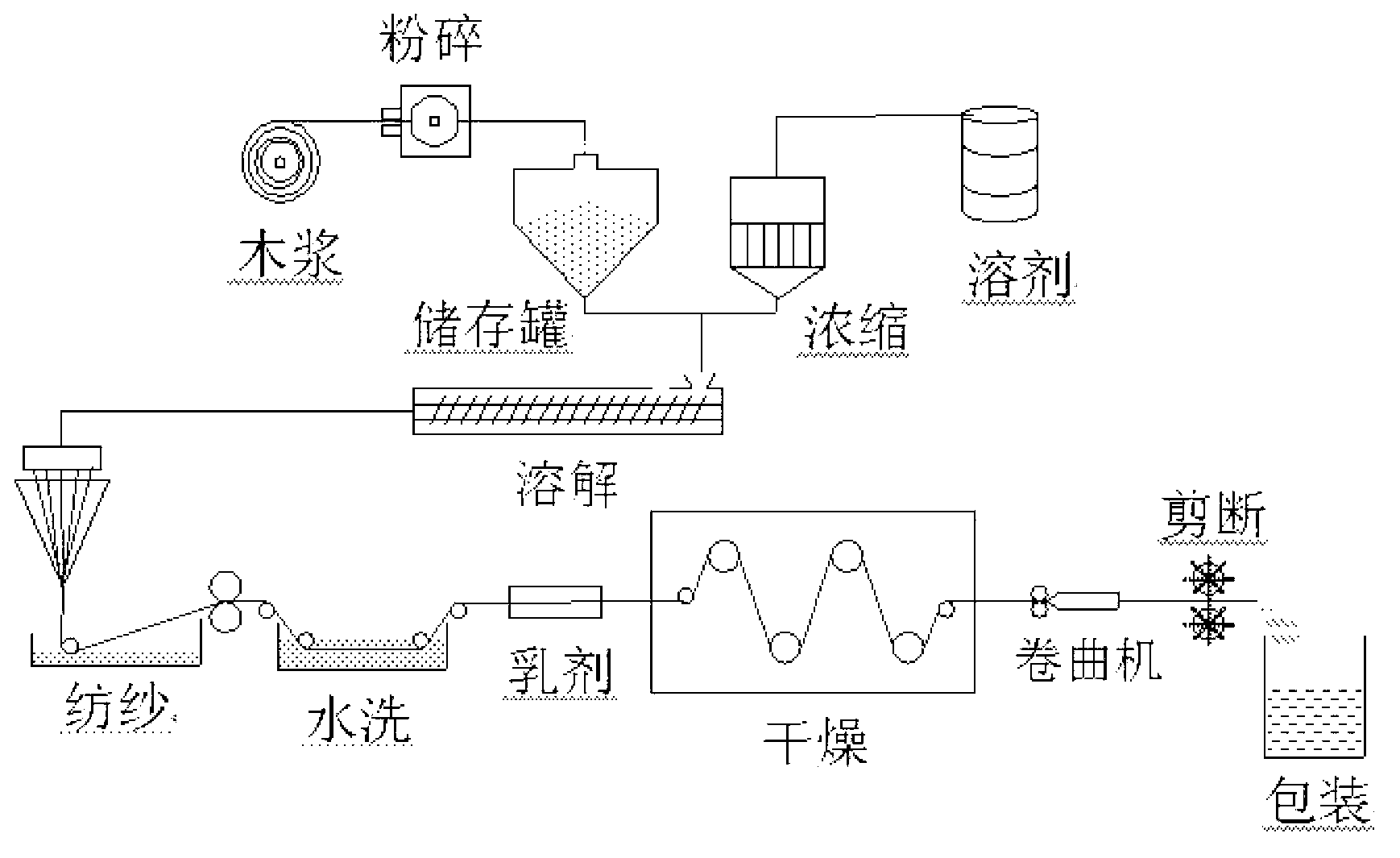

[0088] Example 3: Production of Staple Fibers Using Cotton Linter Slurry

[0089] Put the cotton linter slurry (provided by Mint) with a degree of polymerization (DP) of 1200 into a pulverizer equipped with a 100-mesh filter to produce a slurry powder with a diameter of less than 1700 μm.

[0090] The above-mentioned slurry powder was swollen in a 50% by weight NMMO aqueous solution. At this time, the content of the slurry in the above-mentioned NMMO aqueous solution was 6% by weight, and 0.01% of an oxidation inhibitor was added with respect to the weight of the above-mentioned cotton linter.

[0091] While maintaining the internal temperature of the above-mentioned swollen slurry at 90° C., inject it into a mixer with an absolute pressure of 50 mmHg at a rate of 16 kg / hour using a rotary piston pump, and make 50% by weight after removing excess water. The NMMO aqueous solution becomes an 89% by weight NMMO aqueous solution, and after the slurry is completely dissolved, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com