Polishing device for polishing a metal product

A grinding and product technology, applied in the direction of machine tools, metal processing equipment, grinding/polishing equipment, etc. suitable for grinding workpiece planes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

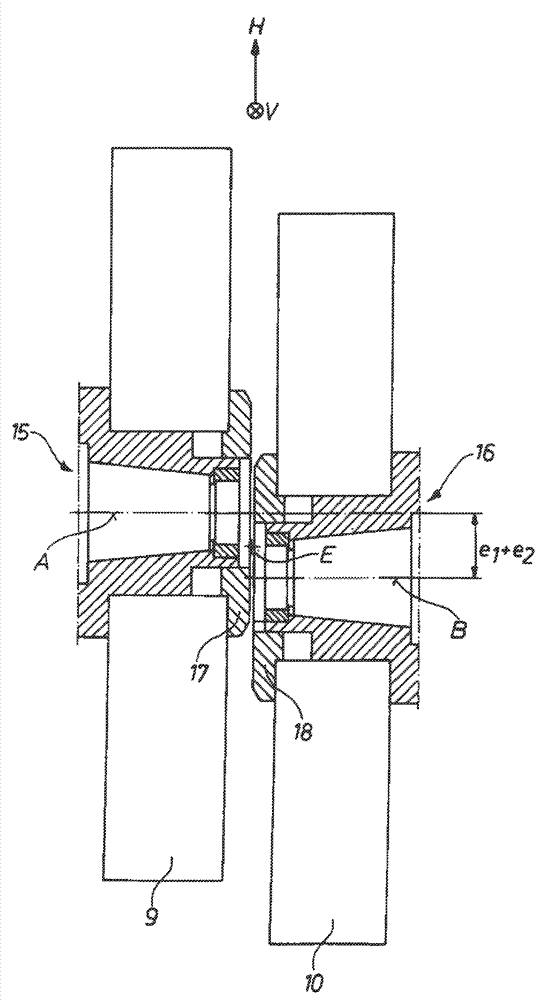

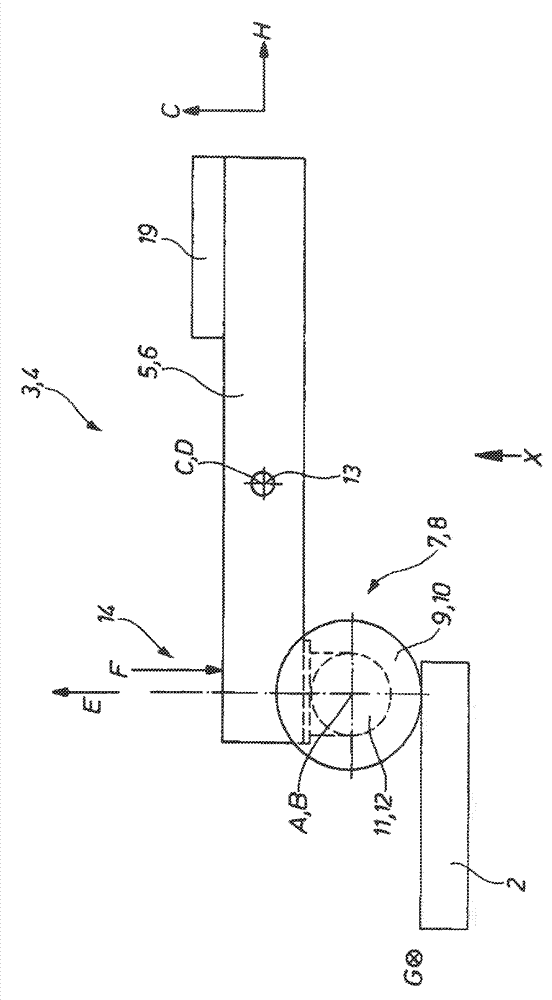

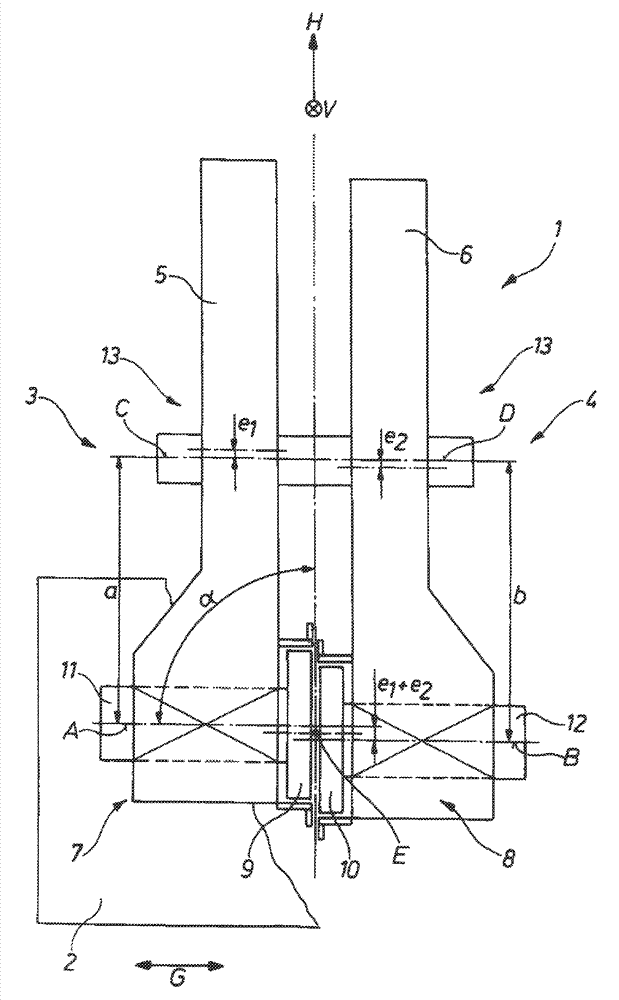

[0021] exist figure 1 with figure 2 Grinding assemblies 3, 4 are shown in image 3 The components of the grinding device 1 seen in .

[0022] The grinding unit 3 , 4 has a support 5 , 6 which is designed as a pivot console with a counterweight 19 . The supports 5 , 6 are mounted pivotably about pivot axes C, D. The grinding unit 3 , 4 has a grinding unit 7 , 8 and has a supported grinding disc 9 , 10 which is directly driven by a drive motor 11 , 12 . The grinding disc rotates about axes of rotation A, B.

[0023] In order to apply the desired pressing force F to the metal product 2 to be ground, an application device 14 , which is only briefly indicated, for example in the form of a piston-cylinder system, is provided.

[0024] Also shown is a means 13 with which the distance between the pivot axes C, D and the rotation axes A, B can be varied. Currently, the axes of rotation A, B can be adjusted or adjusted in the horizontal direction H relative to the axes of pivotin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com