Fast heating device for high-temperature split Hopkinson pressure bar experiment

A Hopkinson pressure rod and rapid heating technology, which is applied in the direction of measuring devices, induction heating, instruments, etc., can solve the problems of slow heating speed, serious surface oxidation, plastic deformation, etc., to achieve accurate installation, ensure safety, and improve The effect of heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

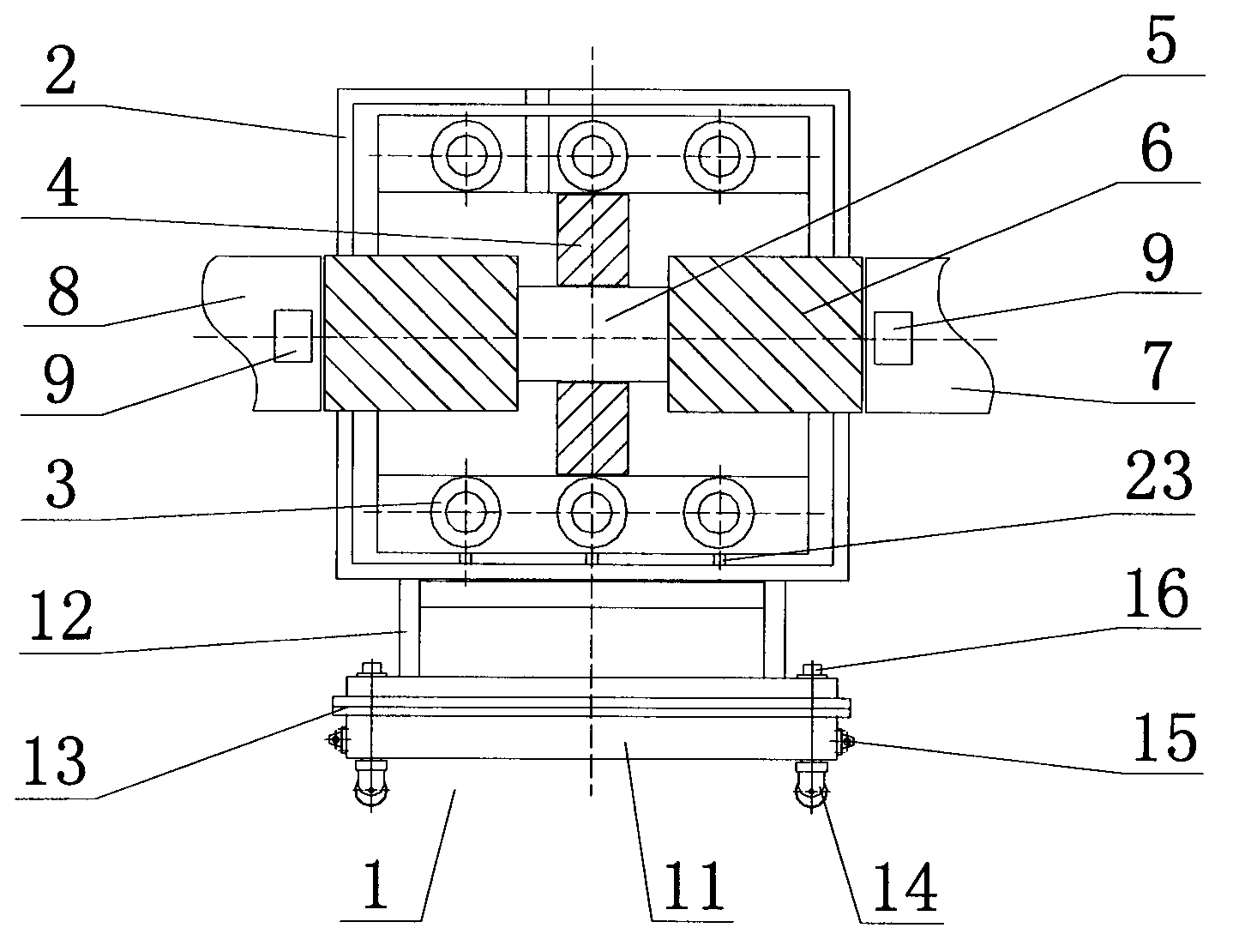

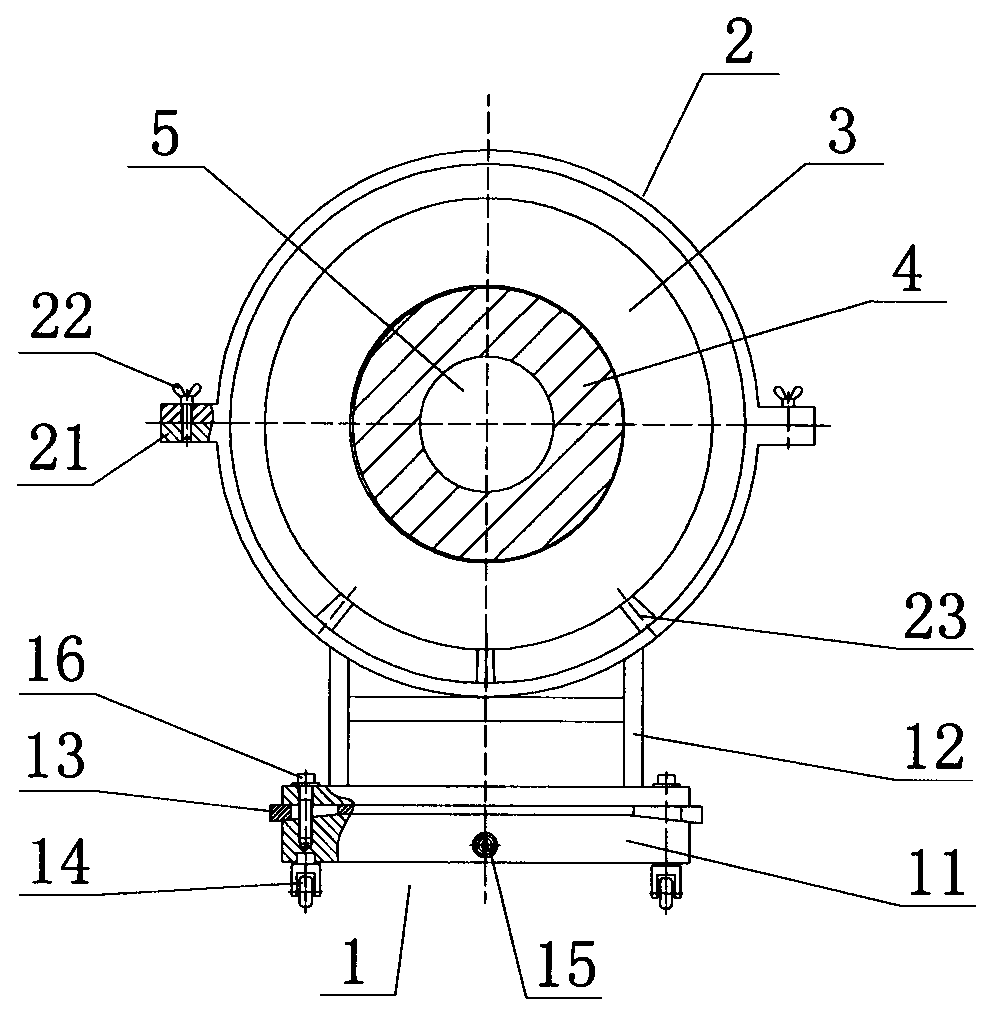

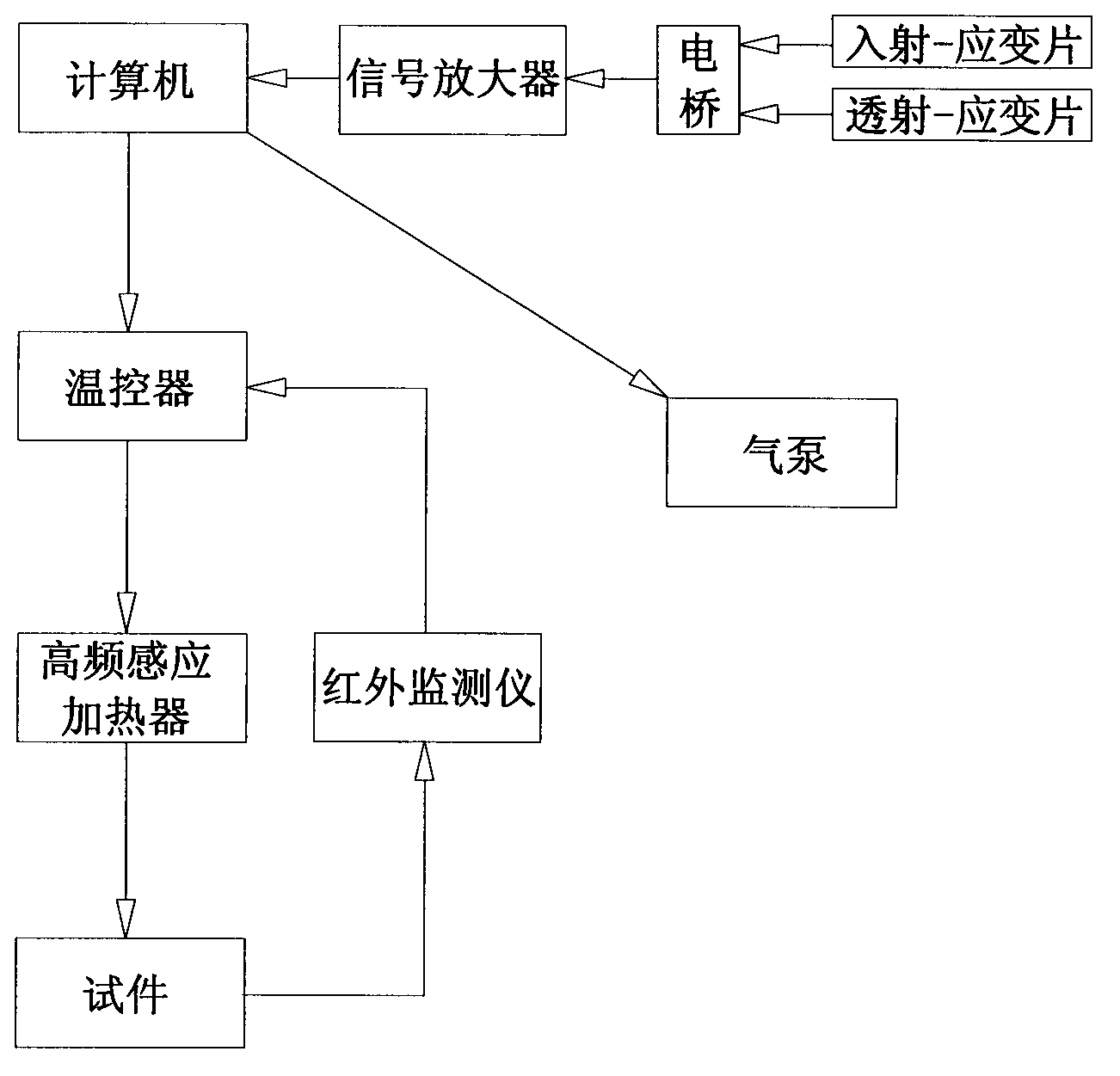

[0035]In conjunction with the accompanying drawings, a rapid heating device for high-temperature Hopkinson pressure bar experiments, which includes a supporting trolley 1 outside the shielding cover 2, in order to ensure that the high-frequency induction heater and the test piece in the shielding cover are flexible, fast and convenient , Accurate installation, in order to ensure the safety and reliability of the high-frequency induction heater in the shield to heat the test piece, in order to save the troublesome process of moving the pressing rod or heating furnace by mechanical devices before and after heating the test piece, to realize the test The heating and impact of the piece are carried out at the same position, which greatly improves the heating speed and eliminates the influence of the oxidation of the test piece on the material properties of the test piece during the heating process; Adjustable pads 13 and locking bolts 16 are provided, casters 14 are provided at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com