Optical fiber routing indicator and method for manufacturing same

An optical fiber and routing technology, applied in the field of optical fiber routing marking and its manufacturing, can solve the problems of difficult application of urban fiber-to-the-home network, large thickness of glass substrate, complicated process, etc., and achieve easy storage and transportation, cost reduction, and process reduction. The effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

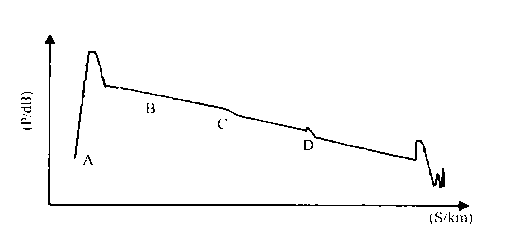

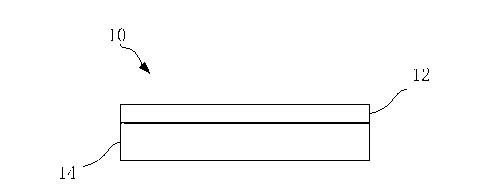

[0023] Such as Figure 4 As shown, the present invention provides an optical fiber routing marking device 10, which uses a flexible material as a substrate 14, and an optical film 12 is coated on it. The flexible material can transmit light, preferably polyimide. Wherein, the thickness of the substrate 14 is smaller than the wavelength of the signal in the optical fiber, thereby reducing the insertion loss. Preferably, the substrate 14 is less than 400 nanometers thick. Wherein, the optical film 12 only reflects the light emitted by the OTDR, but can transmit the service signal.

[0024] In an embodiment of the present invention, the service signal wavelengths may be 1270nm, 1310nm, 1550nm and 1650nm.

[0025] The wavelength of light emitted by OTDR is generally 1610nm, 1625nm or 1650nm.

[0026] Such as Figure 5 As shown, the present invention also provides a method 20 for manufacturing the optical fiber marking routing device, including coating an optical film on a lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com