High speed spindle motor

A spindle and high-speed technology, applied in the field of high-speed spindle motors, can solve the problems of complex combination of mechanical parts, affecting production efficiency, large energy loss, etc., and achieve the effect of compact structure, zero energy loss, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

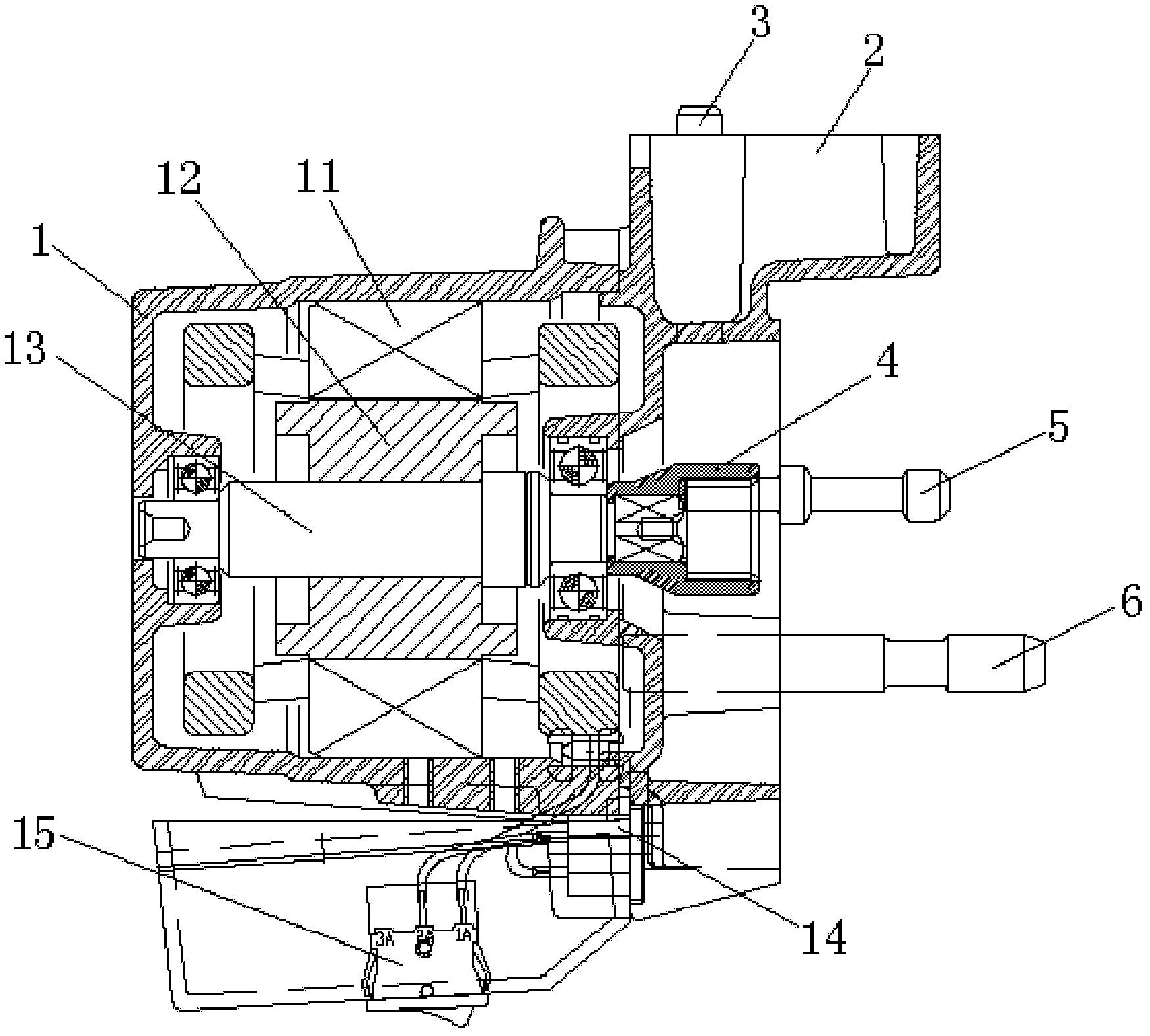

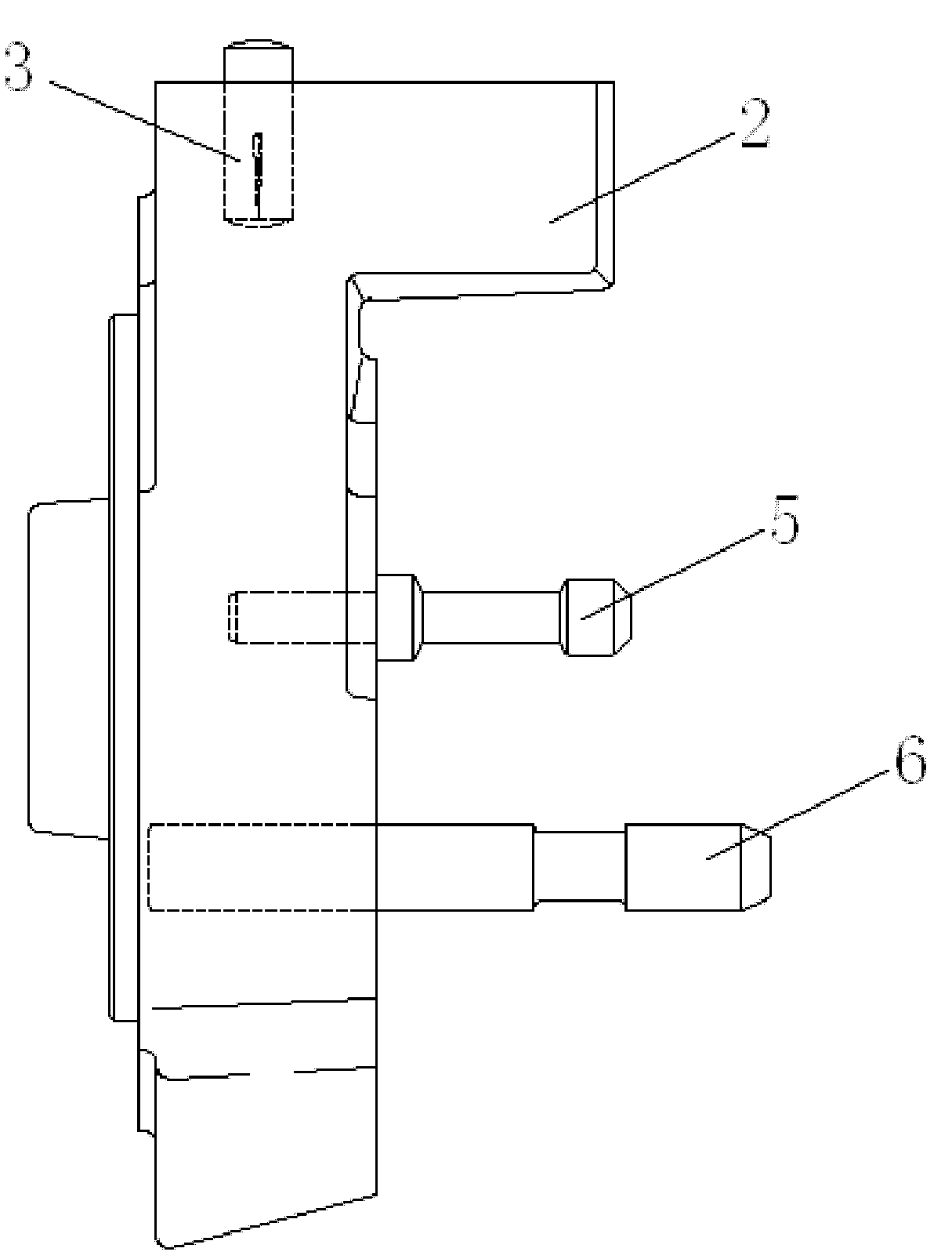

[0025] See figure 1 with figure 2 , This embodiment is a two-pole asynchronous motor, including a housing 1, a cover plate 2, a bolt 3, a coupling 4, a false twister spindle pin 5 and a false twister self-locking shaft 6.

[0026] The driving voltage of the motor is 400V, the frequency is 0Hz-350HZ, and the rated current is 0.45A. The shell 1 is integrally formed of pure aluminum alloy, with exquisite appearance and workmanship, good heat resistance and heat dissipation, which well solves the problem of high temperature heat dissipation of high-speed motors. The housing 1 and the cover plate 2 are fixedly connected by bolts 3 . The housing 1 is provided with a spindle winding 11 , a motor rotor 12 , an output shaft 13 , a steering switch 14 , and a motor start-stop switch 15 . The spindle winding 11 is fixed in the housing 1 . The motor rotor 12 is fixed on the output shaft 13 . The output shaft 13 is rotatably connected with the casing 1 . The steering switch 14 is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com