Electronic tag manufacturing method

A technology of electronic tags and manufacturing methods, which is applied in the field of radio frequency communication, can solve problems such as difficult use of metal surfaces, large size of electronic tags, and poor environmental adaptability of products, and achieve simple and easy manufacturing methods, convenient production, and good market competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

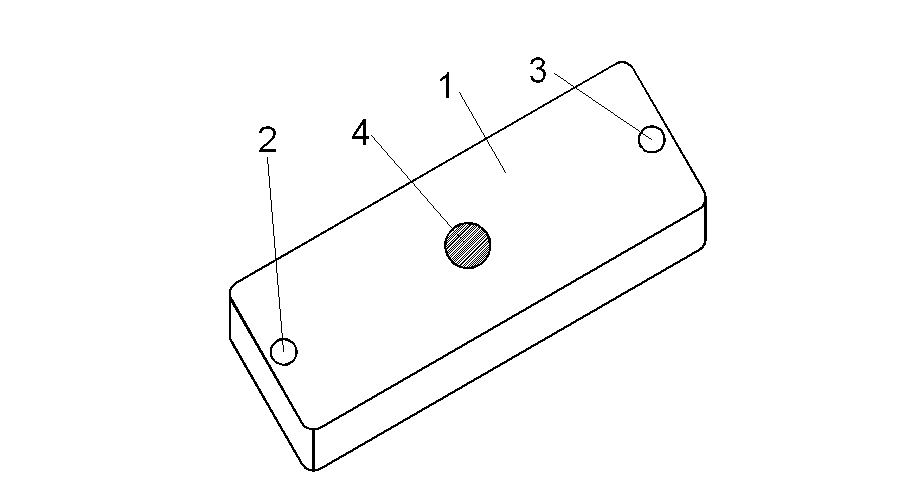

[0033] Adopting the manufacturing method of the electronic tag of the present invention can realize the industrialized production of small ultra-high frequency electronic tags, realize the miniaturization of the volume of ultra-high frequency electronic tags and products with high reliability, and then provide technical solutions and specific implementation methods as follows:

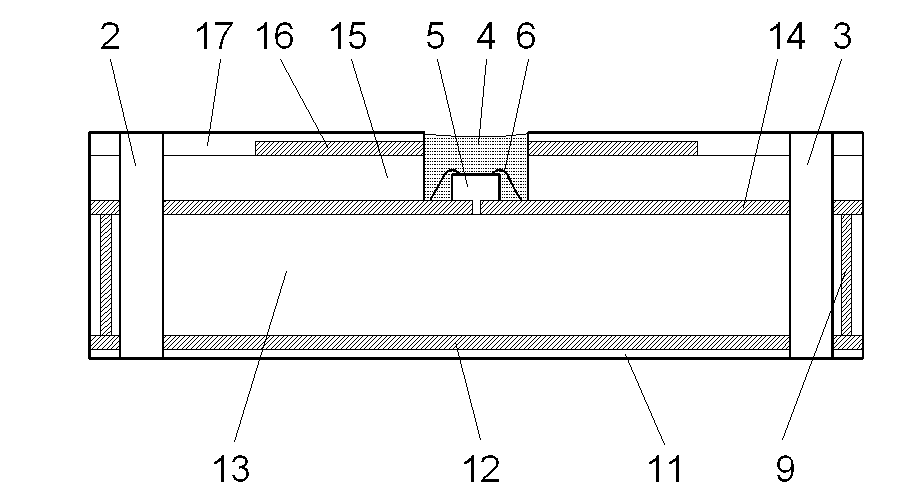

[0034] see figure 2 The cross-sectional schematic diagram of the electronic tag of the present invention, the antenna of the electronic tag is composed of the bottom solder resist layer 11, the ground plane metal layer 12, the antenna insulating medium layer 13, the signal radiation unit layer 14, the capacitor insulating medium layer 15, the capacitor The metal layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com