Exposure machine

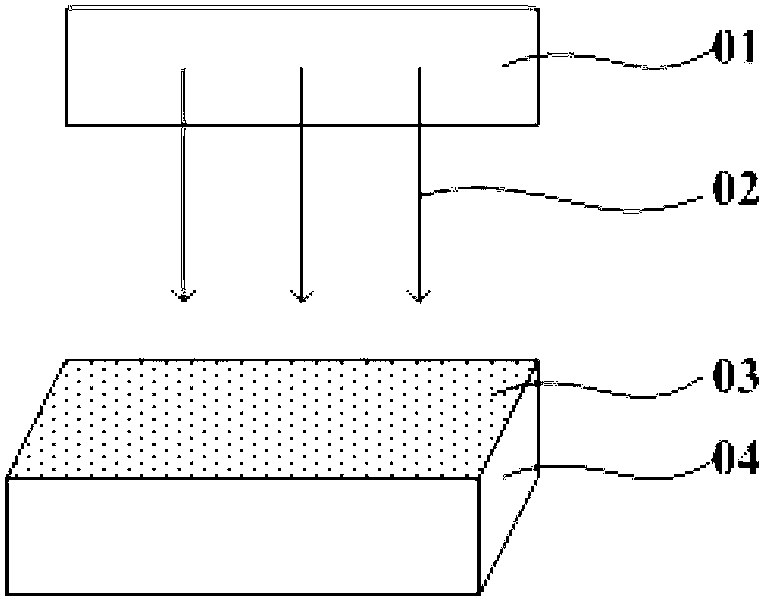

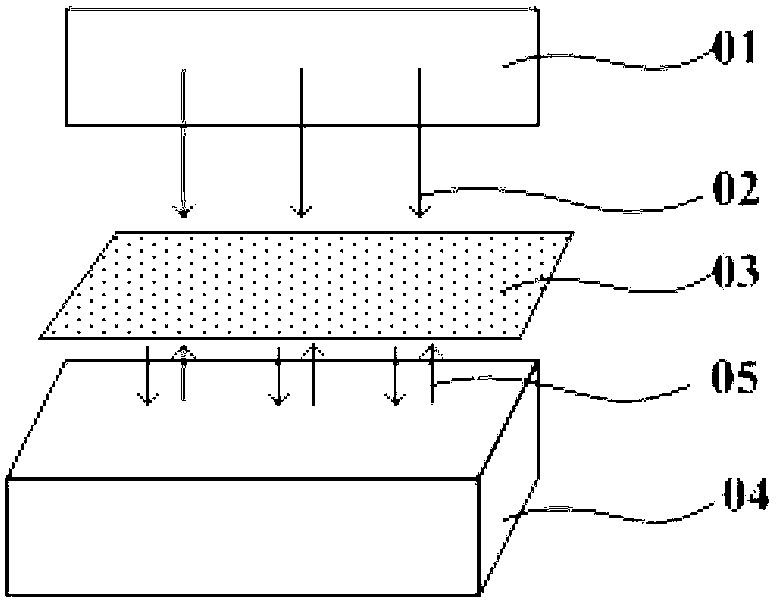

A technology of exposure machine and light source device, which is applied in the field of exposure machine, can solve the problems of particle adhesion, easy generation of static electricity, etc., and achieve the effect of avoiding spots and improving exposure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

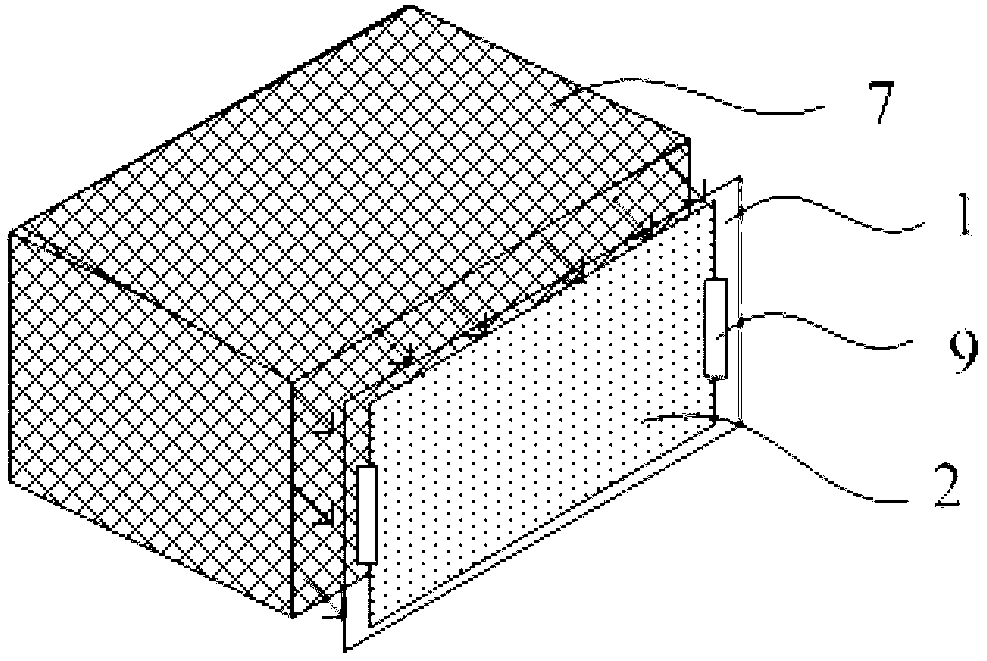

[0030] In order to avoid the spots on the stage generated during exposure, an embodiment of the present invention provides an exposure machine. In this technical solution, the object stage of the exposure machine adopts an object frame structure, and a fixing piece is arranged inside the object frame, and the object to be exposed is fixed in the object frame through the fixing piece, and the exposure light cannot be reflected after passing through the object to be exposed. Therefore, the stage spot on the object to be exposed is avoided, and the exposure quality is improved. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

[0031] like image 3 As shown, the exposure machine of the embodiment of the present invention includes:

[0032] The loading frame 1, the inner side of the frame of the loading frame 1 is provided with a fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com