Gas chromatograph with oil-gas separation function and gas chromatography process for determination of trace moisture in insulating oil

A gas chromatograph and functional technology, applied in the field of gas chromatographic analysis, can solve the problems of high performance requirements of the sampler, contamination of the thermal conductivity cell, damage to the chromatograph, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

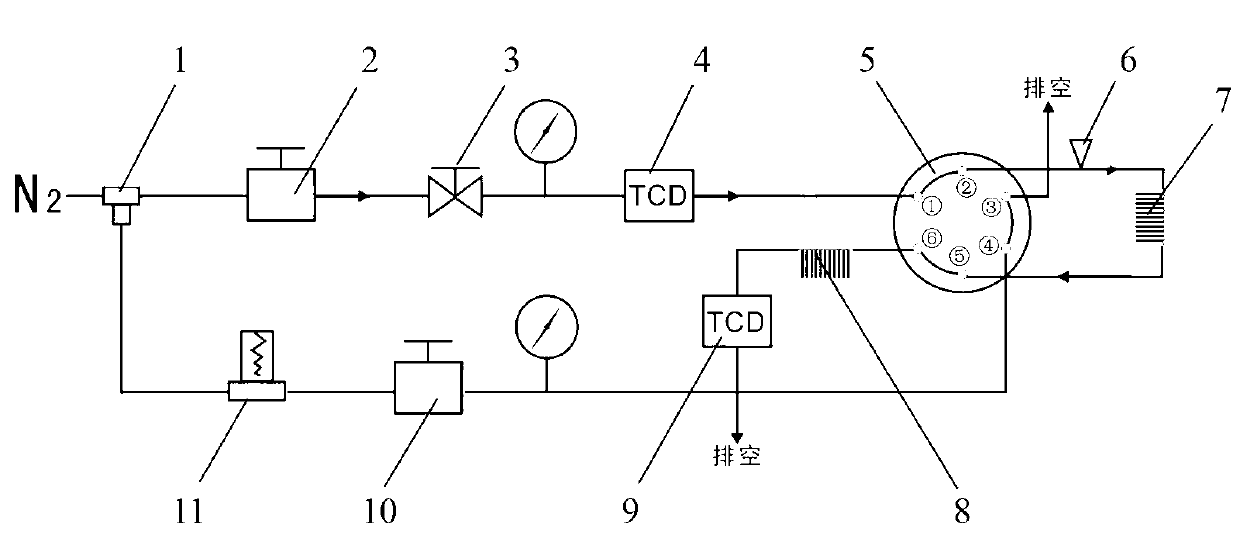

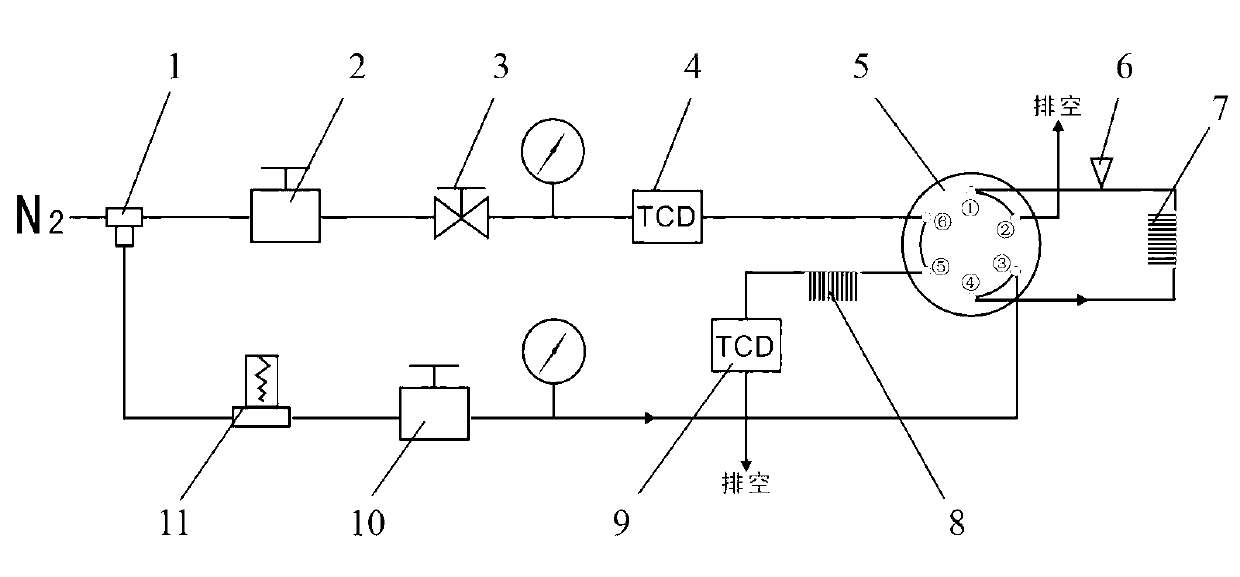

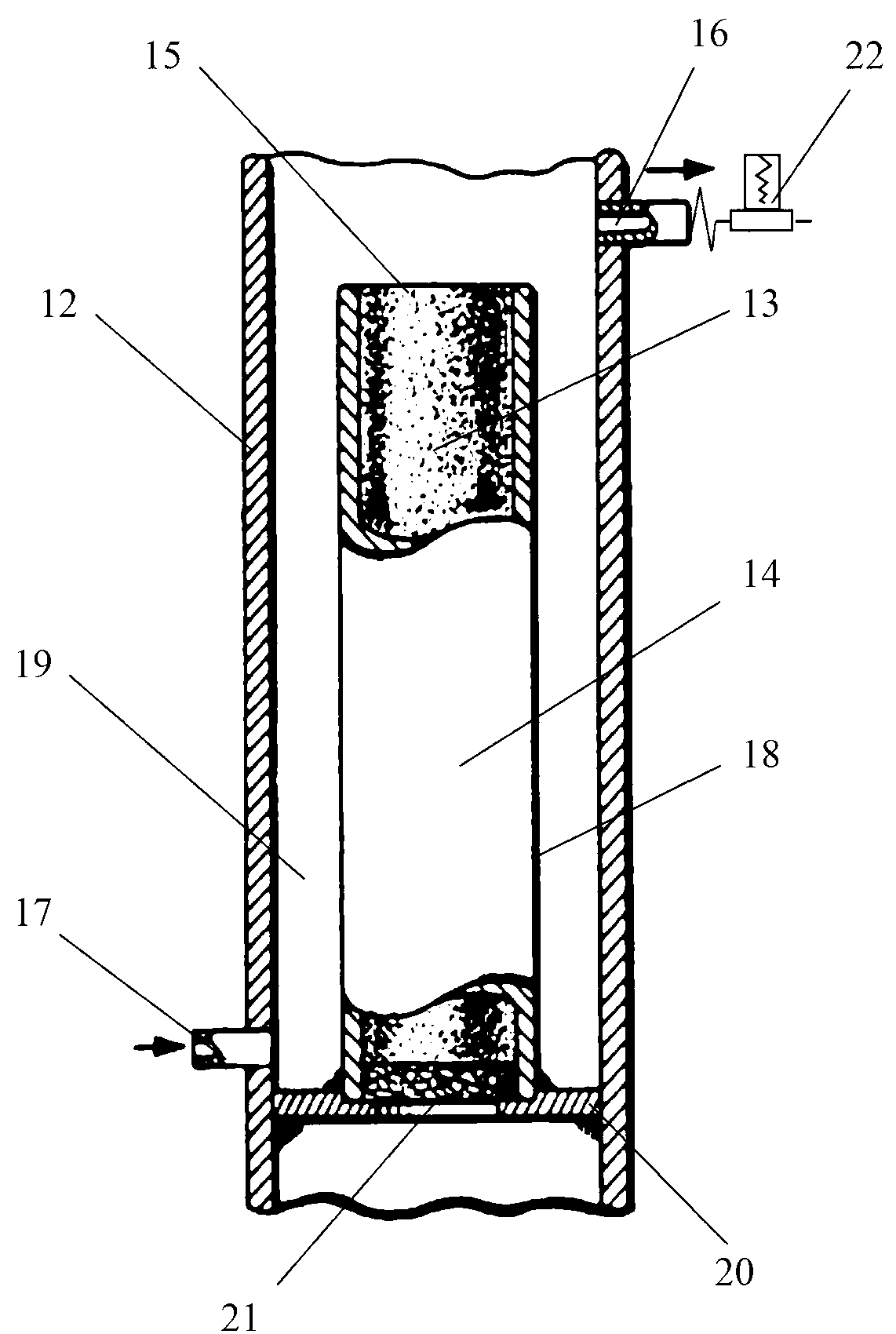

[0024] Example 1 A gas chromatograph with oil-gas separation function, see figure 1 , figure 2 , image 3 , the gas path structure contains a thermal conductivity detector, an analytical chromatographic column 8 (with an inner diameter of 2mm, and a column length of not less than 1.8m, and a polymer porous microsphere filler, such as GDX502, GDX301 or GDX102), and a protective chromatographic column 7 ( The inner diameter is 2mm, and the column length is about one-tenth of the analytical column. Polymer porous microsphere packing is used, such as GDX502, GDX301 or GDX102), six-way valve 5, injector 6, three-way valve 1, pressure regulator valve A 2 and regulator valve B 11, needle valve 3 with pressure gauge, solenoid valve A 10 and solenoid valve B 22, the air inlet of the three-way valve 1 is connected to the carrier gas source, and its two outlets are respectively connected to the detection gas circuit and the blowback air path, the detection air path is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com