Novel high-temperature erosion-resistant thermocouple protection sleeve and production method thereof

A technology for protective sleeves and thermocouples, applied to thermometers, measuring heat, and parts of thermometers, etc., can solve the problem of material loss on the surface of thermocouple protective sleeves, the impact of long-term safe operation of boilers, and insufficient high-temperature erosion resistance, etc. Problems, to achieve excellent high temperature salt corrosion resistance, excellent electrochemical corrosion resistance, excellent high temperature erosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

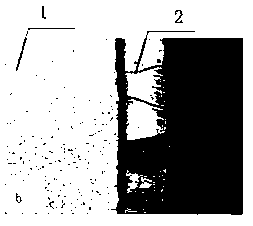

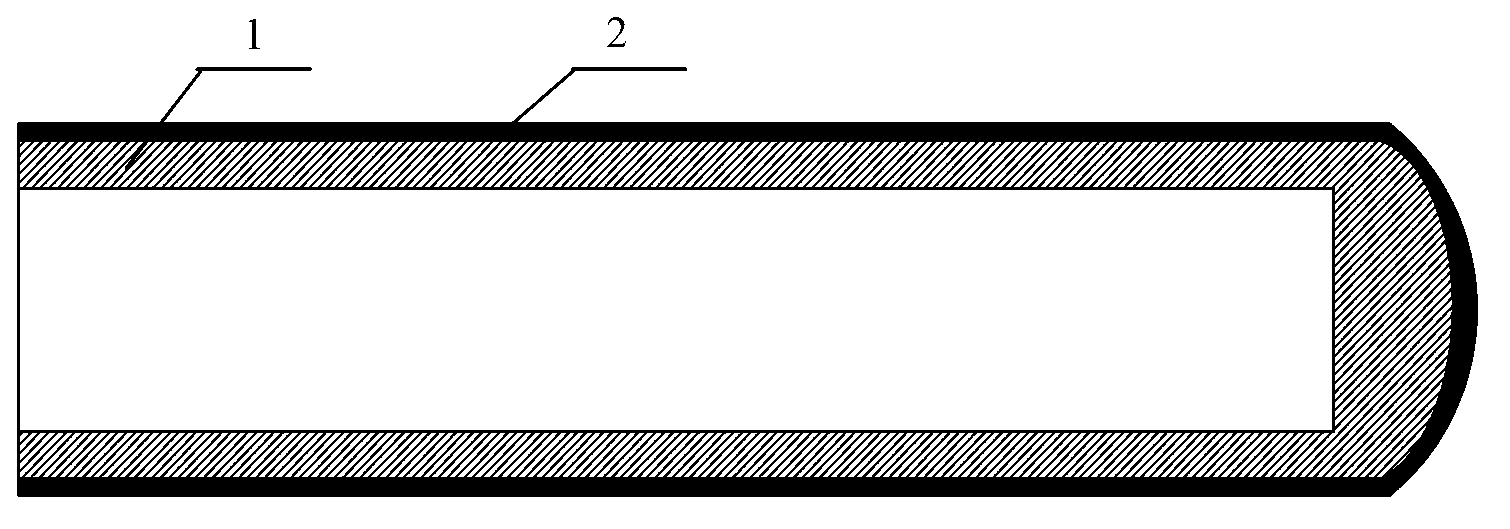

[0026] Such as figure 1 As shown, the protection sleeve of the present invention is a FeAl intermetallic compound single-phase coating 2 with a B2 structure on the surface of the austenitic stainless steel thermocouple protection sleeve base 1, and this intermetallic compound coating 2 is directional growth Characteristic columnar B2-FeAl intermetallic compound coating. From Figure 2a and Figure 2b It can be seen that coating 2 has a typical columnar crystal structure, and the coating structure is relatively uniform.

[0027] The preparation method of the present invention will be described in detail below with a specific example, which is not intended to limit the protection scope of the present invention.

[0028] The first step is to select 1.6kg of pure Al powder, 1.1kg of Fe powder and 1.2kg of Ni powder with a purity of ≥99.0% and a particle size of about 70μm (approximately atomic ratio 3:1:1), and put them into a ball mill for 20 minutes. The rotational speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com