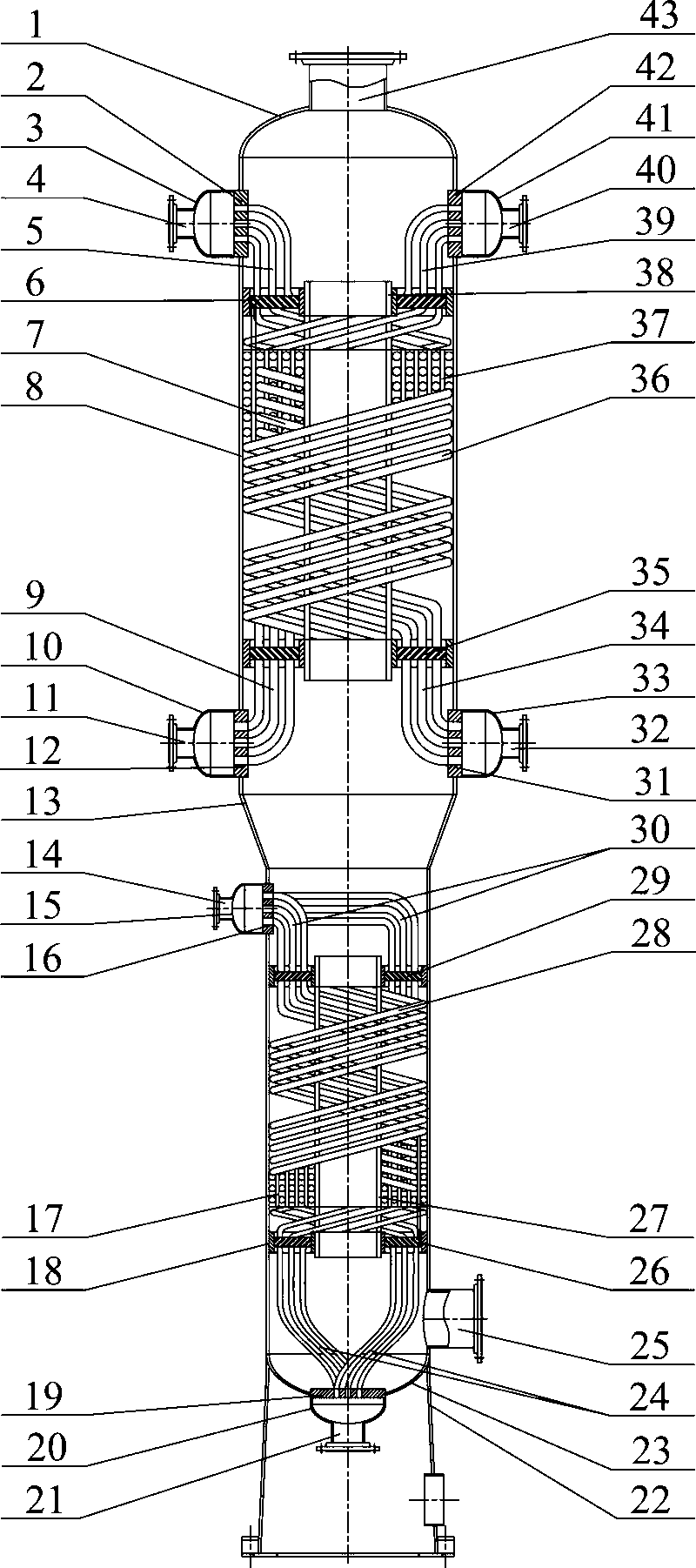

Low-temperature spiral wound heat exchanger for non-converted gas cooler

A winding tube type cooler technology, applied in heat exchanger types, indirect heat exchangers, climate sustainability, etc., can solve problems such as complex heat transfer process, small heat transfer area, and reduced heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First, process and manufacture the main components of the low-temperature coiled tube heat exchanger for the unshifted gas cooler, including the upper head (1), the synthesis gas outlet tube sheet (2), the synthesis gas outlet pipe box (3), and the synthesis gas outlet connection ( 4), synthesis gas outlet tube bundle (5), first support ring (6), synthesis gas winding tube bundle (7), double flow shell (8), double flow tail gas inlet pipe bundle (9), double flow tail gas Inlet pipe box (10), double-stream exhaust gas inlet connector (11), dual-stream exhaust gas inlet tube plate (12), tapered transition shell (13), single-stream exhaust gas outlet connector (14), single-stream exhaust gas Exhaust gas outlet tube box (15), single-stream exhaust gas outlet tube plate (16), single-stream tube bundle partition (17), single-stream shell (18), single-stream exhaust gas inlet tube plate (19), single Stream exhaust gas inlet pipe box (20), single stream exhaust gas inlet connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com