Waste heat recovery heating system of biomass power plant

A waste heat recovery and heating system technology, which is applied in the circulation cooling water of biomass power plants, slag waste heat recovery heating system, and flue gas fields, can solve the problems of difficult recovery and utilization of waste heat, and achieve the effect of high heat recovery and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

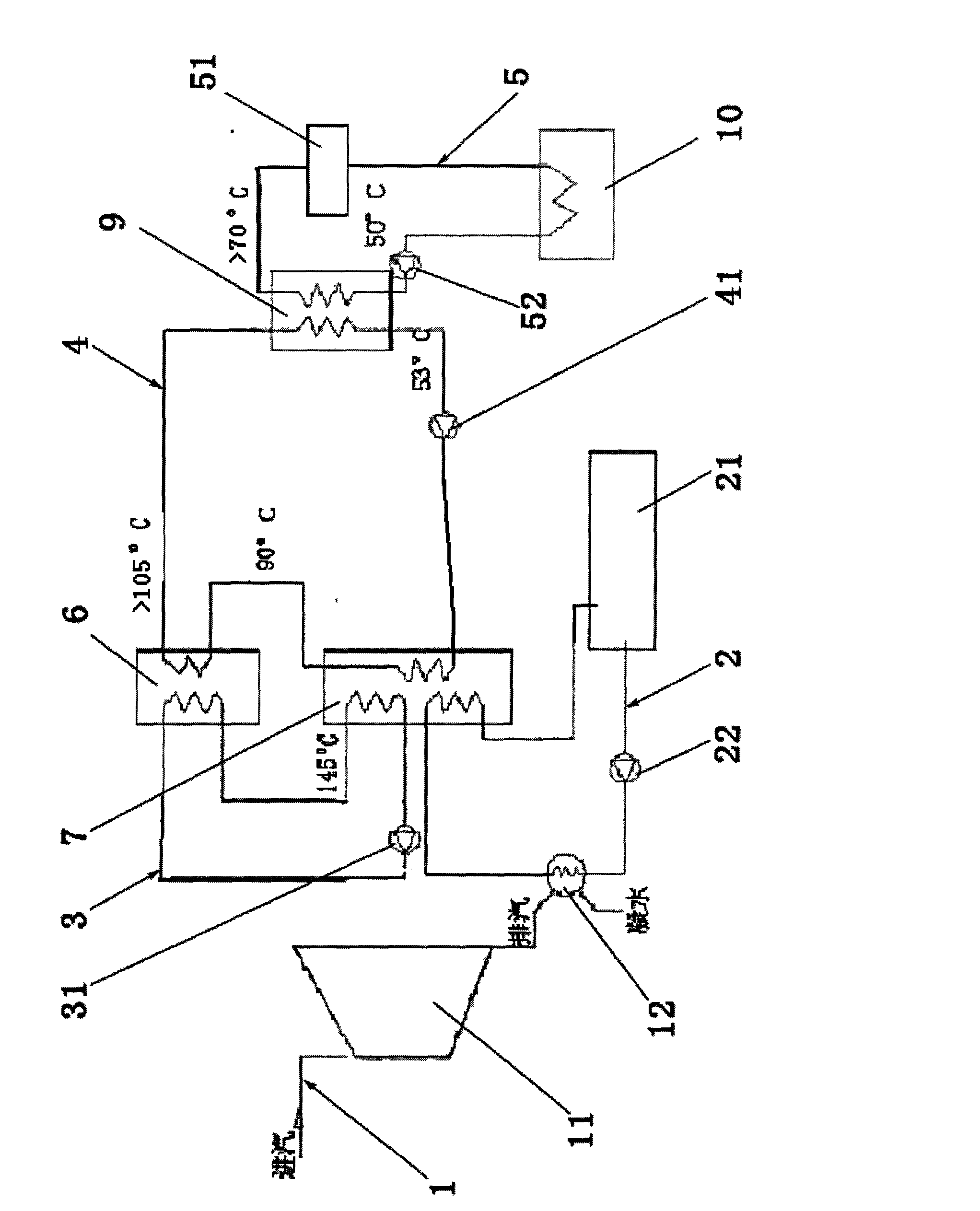

[0016] Attached below figure 1 The present invention is described in further detail with the specific embodiment:

[0017] A biomass power plant waste heat recovery heating system, such as figure 1 As shown, it includes a steam pipeline 1 , a circulating cooling water pipeline 2 , a flue gas heat exchange pipeline 3 , an internal circulation pipeline 4 and a heat supply pipeline 5 .

[0018] The steam pipeline 1 is connected to the steam turbine 11 and the condenser 12; the circulating cooling water pipeline 2 starts from the cooling circulating water pool 21 and returns to the cooling circulating water pool 21 after passing through the circulating cooling water pump, the condenser 12 and the absorption heat pump 7. After the steam in the steam pipeline 1 passes through the steam turbine 11 to do work, the exhaust steam discharged from the turbine 11 is transported to the condenser 12, and the exhaust steam passes through the condenser 12 to transfer heat energy to the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com